NY 144-1988

基本信息

标准号: NY 144-1988

中文名称:小磨香油检验规程

标准类别:农业行业标准(NY)

标准状态:现行

发布日期:1988-01-27

实施日期:1988-08-01

出版语种:简体中文

下载格式:.rar .pdf

下载大小:1881751

标准分类号

关联标准

出版信息

出版社:中国标准出版社

书号:155066·2-7028

页数:4页

标准价格:8.0 元

出版日期:1988-08-01

相关单位信息

发布部门:中华人民共和国农牧渔业部

标准简介

本标准适用于采用水代法生产的小磨香油主要工序的检验,不适用于采用其它工艺生产的芝麻油的检验。当企业的生产工序与本标准规定的检验工序不一致时,企业可参照本标准自行制定检验规程,但成品油的检验应按本标准执行。 NY 144-1988 小磨香油检验规程 NY144-1988 标准下载解压密码:www.bzxz.net

标准图片预览

标准内容

NOTiCE: This standard has either been superseded and replaced by a new version or withdrawn.ContactUoP(methods@uop.com)forthelatestinformation.COPPERINGASOLINEANDNAPHTHA

UoPMethod144-88

This method is for determining low concentrations of copper present as a hydrocarbon-soluble form ingasoline, kerosine and similar distillates. It is particularly useful on products that have been coppersweetened. The lower limit of detection is 5 μg of copper per liter of sample (approximately 6 parts perbillion). Silver and bismuth may interfere. However, the presence of these metals in a sample ofhydrocarbon is unlikely. The complexation with ethylene-diaminetetraacetate (EDTA) and citrate preventsinterferencefrom all othermetals.OUTLINEOFMETHOD

An aqueous

extract containing the copper is prepared. To this is added a solution of sodiumdiethyldithiocarbamate which forms a yellow-colored complex with copper. The colored complex isextracted quantitatively with butyl acetate.Determination of the copper present is made by comparing the intensity of the yellow color,spectrophotometrically or visually, to standards.APPARATUS

Balance, readability 0.1-mg

Beakers, 30- and 100-mL, Fisher Scientific, Cat. No. 02-540-F and H, respectively, or equivalentBottle, polyethylene, 1000-mLCells, spectrophotometer, glass, cylindrical, 20-mm light path, matched set of 2 cells, Fisher Scientific,Cat.No.14-385-932D,orequivalentCuvettes, round, for visual color comparison only, 105-mm high x 19-mm diameter, Fisher Scientific,Cat.No.14-385-900D,orequivalentCylinders, graduated, 25-, 500- and 1000-mL, Fisher Scientific, Cat. Nos. 08-550-C, -G, -H, respectivelyor equivalent

Flasks, volumetric, 250-, 500- and 1000-mL, Class AIT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE PRECAUTIONARY PRACTICES AND TODETERMINETHEAPPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE.EFFECTIVE HEALTH ANDSAFETYPRACTICES ARE TO BE FOLLOWED WHEN UTILIZING THIS PROCEDURE.FAILURETO UTILIZE THISPROCEDURE IN THE MANNER PRESCRIBED HEREIN CAN BE HAZARDOUS.MATERIAL SAFETY DATA SHEETS(MSDS)OREXPERIMENTALMATERIALSAFETYDATASHEETS (EMSDS)FORALLOFTHEMATERIALSUSED INTHIS PROCEDURE SHOULD BE REVIEWED FOR SELECTION OF THE APPROPRIATE PERSONAL PROTECTIONEQUIPMENT (PPE).

C COPYRIGHT 1970, 1988 UOP LLCALL RIGHTS RESERVED

UOP Methods are available through ASTM Intemational, 100 Barr Harbor Drive, PO Box C700, West Conshohocken PA 19428-2959,United States. The Methods may be obtained through the ASTM website, www.astm.org., or by contacting Customer Service atservice@astm.org,610.832.9555FAx,or610.832.9585PHONE.2of6

Funnel, powder, polypropylene, 65-mm diameter, Fisher Scientific, Cat. No. 10-348A, or equivalentFunnels, separatory, 125- and 1000-mL with Teflon stopcocks and polyethylene stoppers, FisherScientific Cat. Nos. 10-437-11C and -F, respectively, or equivalentpH indicator strips, papers, ColorpHast, pH 0 to 14, EM Science, Sargent-Welch Scientific. Cat. No. S-65271,orequivalent

Pipets, Mohr, long-tip, 2- and 5-mL, Fisher Scientific, Cat. Nos. 13-664-8J and -K, or equivalentPipets, volumetric, Class A, 10-, 15-, 20- and 25-mL, Fisher Scientific, Cat. Nos. 13-650-2L, -M, -N and-P,respectively,orequivalentScoop-spatula-spoon, porcelain, Fisher Scientific, Cat. No. 14-430A, or equivalentSpectrophotometer, 5-mm band pass, photometric stability of ± 0.003 absorbance units near zeroabsorbance, Milton Roy Co., Model 601, available from Fisher Scientific, Cat. No. 14-385-267, orequivalent

REAGENTSANDMATERIALS

All reagents shall conform to the specifications established by the Committee on Analytical Reagents ofthe American Chemical Society, when such specifications are available, unless otherwise specifiedReferences to water mean deionized by polystyrene amberlite type resins. The water must meet Type IIrequirements described in ASTM D 1193. Unqualified references to solutions mean aqueous solutions.Ammonium hydroxide, concentrated,28-30%,J.T.Baker, Cat.No.9721, or equivalentn-Butyl acetate, 99% minimum purity, Fisher Scientific, Cat. No. B-396, or equivalentCarbamate solution, 250 mg/250 mL.Weigh 250 ± 0.1 mg of sodium diethyldithiocarbamate,“carbamate,\ into a 250-mL volumetric flask and dilute to the mark with water.Citric acid, anhydrous, 99.5% minimum purity, Aldrich Chemical Co., Cat. No.25,127-5, or equivalentCitric acid solution, 25 mass/vol-%. Dissolve 62.5 ± 0.01 g citric acid in water in a 250-mL volumetricflask.Diluteto themark with water and mix.Cupric sulfate, CuSO4·5HO, 98% minimum purity,Fisher Scientific, Cat.No.C-493, or equivalentCopper stock standard, 400 μg Cu/mL. Weigh 1.571 g ± 0.1 mg CuSO4 · 5H20 and transfer to a 1000-mL volumetric flask. Dissolve in water, dilute to the mark and mix. Prepare fresh monthly and store ina polyethylene bottle.

Copper working standard, 10 μg Cu/mL. Pipet 25 mL of the copper stock standard into a 1000-mLvolumetric flask, dilute to the mark with water and mix. Prepare on a daily basis as needed and store ina polyethylene bottle.

EDTA, disodium salt, dihydrate, J. T. Baker, Cat. No. 1-8993, or equivalentEDTA solution, 4 mass/vol-%.Dissolve 20 ± 0.01 g of EDTA disodium salt in about 400 mL of watercontained in a 500-mL volumetric flask. Dilute to the mark with water and mix.Hydrochloricacid,concentrated,37%144-88

Hydrochloric acid, approximately 4-M. Dilute 333 mL of concentrated hydrochloric acid to 1000 mL andmix.

Hydrochloric acid, approximately 1-M. Dilute 83 mL of concentrated hydrochloric acid to 1000 mL andmix.

Sodium hypochlorite,approximately 5% solution.\Clorox\,or any equivalent household bleach issuitable.

Sodium diethyldithiocarbamate,“carbamate\, 99% minimum purity, Fisher Scientific, Cat. No. S-287, orequivalent

Sodium sulfale, granular, 12-60 mesh, 99% minimum purity, J. T. Baker, Cat. No. 3375, or equivalentSTANDARDIZATION

SpectrophotometricAnalysis

Into each of seven 125 mL separatory funnels, place 20 mL of 4-M hydrochloric acid. Using 2- and 5-mLlong-tip Mohr pipets, add 0.2, 0.5, 1, 2, 3 and 4 mL of the copper working standard (10 μg Cu/mL) to thefirst six funnels, respectively. Mix well by swirling affer addition. Add no copper standard to the seventhflask which will serve as a blank. Next add 10 mL of citric acid solution followed by 20 mL of concentratedammonium-hydroxide to each flask. Swirl and allow to cool. Add 15 mL of EDTA solution followed by 10mL of carbamate solution. Again swirl to mix and wait approximately 15 minutes for the copper-carbamatecomplex to form. Add by pipet 20 mL of n-butyl acetate, stopper the separatory funnels and shake for 2minutes, Allow the layers to separate for 2 minutes. Using a pH indicator strip, test a drop of the aqueouslayer to verify that the pH is greater than 9. If not, repeat the above procedure but add approximately 25 mLof ammonium hydroxide. Drain and discard the lower aqueous layer. To the yellow butyl acetate layercontaining the copper complex, add 25 mL of 1-M hydrochloric acid. Stopper and shake for 3o seconds.Allow the layers to separate for 1 minute, drain the lower acidic-aqueous layer and discard.Using the plastic powder funnel and a scoop-spatula-spoon, add to each funnel approximately 5 g ofsodium sulfate. Stopper and shake for one minute to absorb all moisture from the organic phase. Brieflyclean the neck of each flask using a paper towel and, sequentially, decant each extract through the neck ofthe separatory funnel directly into a 20-mm spectrophotometric cell. Measure the absorbance at 430 nm,using n-butyl acetate as the reference solution for the standards and the reagent blank.From the absorbance readings, calculate the net absorbance and plot the net absorbance values versus O,2, 5, 10, 20, 30 and 40 μg of copper per 20 mL of n-butyl acetate. The resulting calibration curve should besimilartotheaccompanyingFigure.PreparationofColorStandardsforVisualComparisonIf visual color comparison of extracts is to be made, prepare the standards as described underSpectrophotometric Analysis and decant the yellow extracts into matched round cuvettes. Prepare samplesfor analysis at the same time to avoid possible color changes.PROCEDURE

The procedure for making a determination is essentially the same whether the colored solution ismeasuredspectrophotometricallyorvisually144-88

With a graduated cylinder place 500 mL of the hydrocarbon sample in a 1000-mL separatory funnel.Pipet 10 mL of the sodium hydrochlorite solution into the funnel and shake vigorously for 5 minutes. Addby pipet 15 mL of 4-M hydrochloric acid and shake for another 5 minutes. Allow the layers to separate anddrain the sodium hypochlorite-acid layer into a clean, dry, 30-mL beaker.Pipet a 20-mL aliquot of the sodium hydrochlorite-acid mixture into a 125 mL separatory funnel. Add 20mL of concentrated ammonium hydroxide, swirl and let cool. Add 25 mL of n-butyl acetate, stopper andshake for 2 minutes to remove any yellow organic color bodies which might later interfere with the yellowcopper-carbamate complex. Allow the layers to separate for 2 minutes and quantitatively collect the loweraqueous layer into a 10-mL beaker. Discard the upper butyl acetate layer, pour the aqueous layer back intothe separatory funnel and repeat the extraction two more times or until the butyl acetate layer is water-white. Return the ammoniacal, aqueous layer to the separatory funnel. Add 10 mL of citric acid solution, 15mL of EDTA-solution followed by 10 mL of carbamate solution. Swirl to mix and allow 15 minutes for thecopper-carbamatecomplextoform.Add by pipet 20 mL of n-butyl acetate, stopper the separatory funnel and shake for 2 minutes. Allow thelayers to separate for 2 minutes. Using a pH indicator strip, test a drop of the aqueous layer to verify that thepH is greater than 9. If not, repeat the analysis but add approximately 25 mL of ammonium hydroxide.Drain and discard the lower aqueous layer. To the yellow butyl acetate layer containing the copper complex,add 25 mL of 1-M hydrochloric acid, stopper and shake for 30 seconds. Allow the layers to separate forapproximately 1 minute, drain the lower acidic-aqucous layer and discard.Using the plastic powder funnel and a scoop-spatula-spoon, add approximately 5 g of sodium sulfate tothe sample extract. Stopper and shake for one minute to absorb all moisture from the organic phase. Brieflyclean the neck of each flask using a paper towel and decant the extract through the neck of the separatoryfunnel directly into a 20-mm spectrophotometric cell. Determine the net absorbance at 430 nm, using n-butyl acetate as the reference solution for the cxtracts and reagent blank. Determine the absorbance within30 minutes of the n-butyl acetate addition and avoid undue exposure to light. If the color is too intense, takea smaller sample volume and repeat the analysis. If a visual comparison is to be made, decant the extractinto a roundcuvette.

Determine the micrograms of copper per 2o mL from the spectrophotometric calibration curve or byvisual comparison to the previously prepared standards.CALCULATIONS

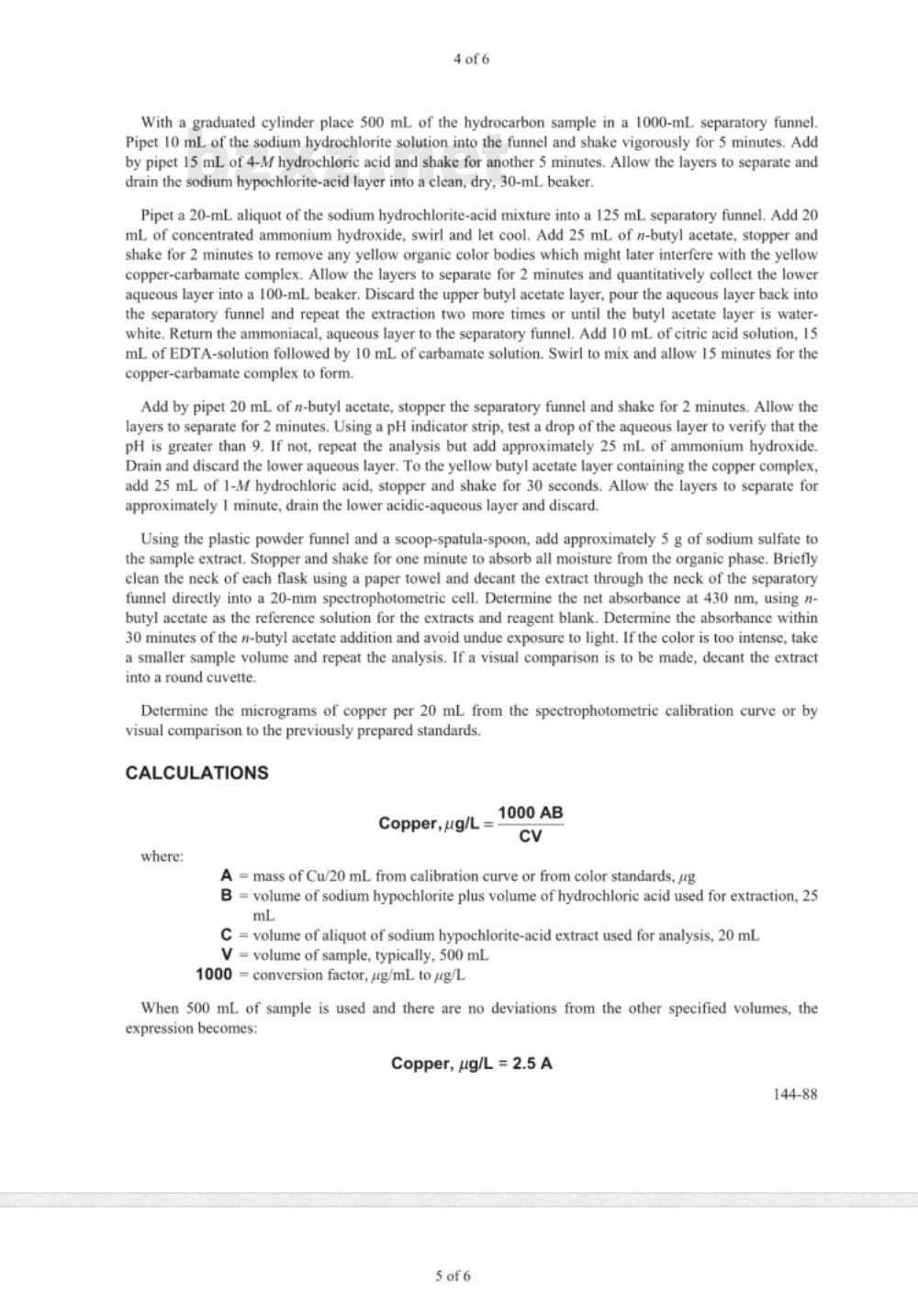

1000AB免费标准bzxz.net

Copper,μg/L=

where:

A=mass ofCu/20mLfrom calibrationcurve orfromcolor standards,μgB = volume of sodium hypochlorite plus volume of hydrochloric acid used for extraction, 25mL

C =volume ofaliquotof sodiumhypochlorite-acid extractused for analysis,20mLV=volumeofsample,typically,500mL1000=conversionfactor,μg/mLto μg/LWhen 5oo mL of sample is used and there are no deviations from the other specified volumes, theexpressionbecomes:

Copper, μg/L = 2.5 A

144-88

whereAisaspreviouslydefined

PRECAUTIONS

Keep all glassware scrupulously clean in order to avoid contamination from copper.Thebestresults areobtained when the glassware is reserved only for these analyses.When extracting the hydrocarbon with the hypochlorite-acid mixture, vent the funnel frequently. Do thisalso when scrubbing the ammoniacal solution with n-butyl acetate.PRECISION

Repeatability

Based on two tests performed by each of two analysts, on each of two days (8 tests), the within-laboratoryestimated standard deviation (esd) was calculated to be 3.27 at a copper concentration of 21 μg/L. Two testsperformed in one laboratory by different analysts on different days should not differ by more than 12.8(95%probability)atthestatedlevel.Reproducibility

There is insufficient data to calculate the reproducibility of the test atthis time.TIMEFORANALYSIS

The elapsed time and labor requirement for calibration and one analysis are identical, 6 hours. In groupsof 4 samples, the elapsed time and labor requirement are 8 hours.REFERENCE

ASTMMethodD1193,www.astm.orgFurman, N. Howell, Editor, Standard Methods of Chemical Analysis, D. Van Nostrand Co., Inc., (1962)Vol.1, 6th ed.,407

SUGGESTEDSUPPLIERS

Aldrich Chemical Co., 940 W. St. Paul Ave., Milwaukee, WI 53233J.T. Baker Chemical Co., 222 Red School Ln., Phillipsburg, NJ 08865Fisher Scientific Co., 711 Forbes Ave., Pittsburgh, PA 15219Sargent-Welch Scientific Co., 7300 N.Linder Ave., Skokie, IL 60077144-88

还剩1页未读,是否继续阅读?

此文档由标准图书馆分享于2018-03-10..

REF.SOLUTION:

n-BUTYLACETATE

20-mmcELL

μgcu/20ml

Figure

Typical Calibration Curve for Determinationof Copper in Gasoline and Naphtha40

144-88

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

UoPMethod144-88

This method is for determining low concentrations of copper present as a hydrocarbon-soluble form ingasoline, kerosine and similar distillates. It is particularly useful on products that have been coppersweetened. The lower limit of detection is 5 μg of copper per liter of sample (approximately 6 parts perbillion). Silver and bismuth may interfere. However, the presence of these metals in a sample ofhydrocarbon is unlikely. The complexation with ethylene-diaminetetraacetate (EDTA) and citrate preventsinterferencefrom all othermetals.OUTLINEOFMETHOD

An aqueous

extract containing the copper is prepared. To this is added a solution of sodiumdiethyldithiocarbamate which forms a yellow-colored complex with copper. The colored complex isextracted quantitatively with butyl acetate.Determination of the copper present is made by comparing the intensity of the yellow color,spectrophotometrically or visually, to standards.APPARATUS

Balance, readability 0.1-mg

Beakers, 30- and 100-mL, Fisher Scientific, Cat. No. 02-540-F and H, respectively, or equivalentBottle, polyethylene, 1000-mLCells, spectrophotometer, glass, cylindrical, 20-mm light path, matched set of 2 cells, Fisher Scientific,Cat.No.14-385-932D,orequivalentCuvettes, round, for visual color comparison only, 105-mm high x 19-mm diameter, Fisher Scientific,Cat.No.14-385-900D,orequivalentCylinders, graduated, 25-, 500- and 1000-mL, Fisher Scientific, Cat. Nos. 08-550-C, -G, -H, respectivelyor equivalent

Flasks, volumetric, 250-, 500- and 1000-mL, Class AIT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE PRECAUTIONARY PRACTICES AND TODETERMINETHEAPPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE.EFFECTIVE HEALTH ANDSAFETYPRACTICES ARE TO BE FOLLOWED WHEN UTILIZING THIS PROCEDURE.FAILURETO UTILIZE THISPROCEDURE IN THE MANNER PRESCRIBED HEREIN CAN BE HAZARDOUS.MATERIAL SAFETY DATA SHEETS(MSDS)OREXPERIMENTALMATERIALSAFETYDATASHEETS (EMSDS)FORALLOFTHEMATERIALSUSED INTHIS PROCEDURE SHOULD BE REVIEWED FOR SELECTION OF THE APPROPRIATE PERSONAL PROTECTIONEQUIPMENT (PPE).

C COPYRIGHT 1970, 1988 UOP LLCALL RIGHTS RESERVED

UOP Methods are available through ASTM Intemational, 100 Barr Harbor Drive, PO Box C700, West Conshohocken PA 19428-2959,United States. The Methods may be obtained through the ASTM website, www.astm.org., or by contacting Customer Service atservice@astm.org,610.832.9555FAx,or610.832.9585PHONE.2of6

Funnel, powder, polypropylene, 65-mm diameter, Fisher Scientific, Cat. No. 10-348A, or equivalentFunnels, separatory, 125- and 1000-mL with Teflon stopcocks and polyethylene stoppers, FisherScientific Cat. Nos. 10-437-11C and -F, respectively, or equivalentpH indicator strips, papers, ColorpHast, pH 0 to 14, EM Science, Sargent-Welch Scientific. Cat. No. S-65271,orequivalent

Pipets, Mohr, long-tip, 2- and 5-mL, Fisher Scientific, Cat. Nos. 13-664-8J and -K, or equivalentPipets, volumetric, Class A, 10-, 15-, 20- and 25-mL, Fisher Scientific, Cat. Nos. 13-650-2L, -M, -N and-P,respectively,orequivalentScoop-spatula-spoon, porcelain, Fisher Scientific, Cat. No. 14-430A, or equivalentSpectrophotometer, 5-mm band pass, photometric stability of ± 0.003 absorbance units near zeroabsorbance, Milton Roy Co., Model 601, available from Fisher Scientific, Cat. No. 14-385-267, orequivalent

REAGENTSANDMATERIALS

All reagents shall conform to the specifications established by the Committee on Analytical Reagents ofthe American Chemical Society, when such specifications are available, unless otherwise specifiedReferences to water mean deionized by polystyrene amberlite type resins. The water must meet Type IIrequirements described in ASTM D 1193. Unqualified references to solutions mean aqueous solutions.Ammonium hydroxide, concentrated,28-30%,J.T.Baker, Cat.No.9721, or equivalentn-Butyl acetate, 99% minimum purity, Fisher Scientific, Cat. No. B-396, or equivalentCarbamate solution, 250 mg/250 mL.Weigh 250 ± 0.1 mg of sodium diethyldithiocarbamate,“carbamate,\ into a 250-mL volumetric flask and dilute to the mark with water.Citric acid, anhydrous, 99.5% minimum purity, Aldrich Chemical Co., Cat. No.25,127-5, or equivalentCitric acid solution, 25 mass/vol-%. Dissolve 62.5 ± 0.01 g citric acid in water in a 250-mL volumetricflask.Diluteto themark with water and mix.Cupric sulfate, CuSO4·5HO, 98% minimum purity,Fisher Scientific, Cat.No.C-493, or equivalentCopper stock standard, 400 μg Cu/mL. Weigh 1.571 g ± 0.1 mg CuSO4 · 5H20 and transfer to a 1000-mL volumetric flask. Dissolve in water, dilute to the mark and mix. Prepare fresh monthly and store ina polyethylene bottle.

Copper working standard, 10 μg Cu/mL. Pipet 25 mL of the copper stock standard into a 1000-mLvolumetric flask, dilute to the mark with water and mix. Prepare on a daily basis as needed and store ina polyethylene bottle.

EDTA, disodium salt, dihydrate, J. T. Baker, Cat. No. 1-8993, or equivalentEDTA solution, 4 mass/vol-%.Dissolve 20 ± 0.01 g of EDTA disodium salt in about 400 mL of watercontained in a 500-mL volumetric flask. Dilute to the mark with water and mix.Hydrochloricacid,concentrated,37%144-88

Hydrochloric acid, approximately 4-M. Dilute 333 mL of concentrated hydrochloric acid to 1000 mL andmix.

Hydrochloric acid, approximately 1-M. Dilute 83 mL of concentrated hydrochloric acid to 1000 mL andmix.

Sodium hypochlorite,approximately 5% solution.\Clorox\,or any equivalent household bleach issuitable.

Sodium diethyldithiocarbamate,“carbamate\, 99% minimum purity, Fisher Scientific, Cat. No. S-287, orequivalent

Sodium sulfale, granular, 12-60 mesh, 99% minimum purity, J. T. Baker, Cat. No. 3375, or equivalentSTANDARDIZATION

SpectrophotometricAnalysis

Into each of seven 125 mL separatory funnels, place 20 mL of 4-M hydrochloric acid. Using 2- and 5-mLlong-tip Mohr pipets, add 0.2, 0.5, 1, 2, 3 and 4 mL of the copper working standard (10 μg Cu/mL) to thefirst six funnels, respectively. Mix well by swirling affer addition. Add no copper standard to the seventhflask which will serve as a blank. Next add 10 mL of citric acid solution followed by 20 mL of concentratedammonium-hydroxide to each flask. Swirl and allow to cool. Add 15 mL of EDTA solution followed by 10mL of carbamate solution. Again swirl to mix and wait approximately 15 minutes for the copper-carbamatecomplex to form. Add by pipet 20 mL of n-butyl acetate, stopper the separatory funnels and shake for 2minutes, Allow the layers to separate for 2 minutes. Using a pH indicator strip, test a drop of the aqueouslayer to verify that the pH is greater than 9. If not, repeat the above procedure but add approximately 25 mLof ammonium hydroxide. Drain and discard the lower aqueous layer. To the yellow butyl acetate layercontaining the copper complex, add 25 mL of 1-M hydrochloric acid. Stopper and shake for 3o seconds.Allow the layers to separate for 1 minute, drain the lower acidic-aqueous layer and discard.Using the plastic powder funnel and a scoop-spatula-spoon, add to each funnel approximately 5 g ofsodium sulfate. Stopper and shake for one minute to absorb all moisture from the organic phase. Brieflyclean the neck of each flask using a paper towel and, sequentially, decant each extract through the neck ofthe separatory funnel directly into a 20-mm spectrophotometric cell. Measure the absorbance at 430 nm,using n-butyl acetate as the reference solution for the standards and the reagent blank.From the absorbance readings, calculate the net absorbance and plot the net absorbance values versus O,2, 5, 10, 20, 30 and 40 μg of copper per 20 mL of n-butyl acetate. The resulting calibration curve should besimilartotheaccompanyingFigure.PreparationofColorStandardsforVisualComparisonIf visual color comparison of extracts is to be made, prepare the standards as described underSpectrophotometric Analysis and decant the yellow extracts into matched round cuvettes. Prepare samplesfor analysis at the same time to avoid possible color changes.PROCEDURE

The procedure for making a determination is essentially the same whether the colored solution ismeasuredspectrophotometricallyorvisually144-88

With a graduated cylinder place 500 mL of the hydrocarbon sample in a 1000-mL separatory funnel.Pipet 10 mL of the sodium hydrochlorite solution into the funnel and shake vigorously for 5 minutes. Addby pipet 15 mL of 4-M hydrochloric acid and shake for another 5 minutes. Allow the layers to separate anddrain the sodium hypochlorite-acid layer into a clean, dry, 30-mL beaker.Pipet a 20-mL aliquot of the sodium hydrochlorite-acid mixture into a 125 mL separatory funnel. Add 20mL of concentrated ammonium hydroxide, swirl and let cool. Add 25 mL of n-butyl acetate, stopper andshake for 2 minutes to remove any yellow organic color bodies which might later interfere with the yellowcopper-carbamate complex. Allow the layers to separate for 2 minutes and quantitatively collect the loweraqueous layer into a 10-mL beaker. Discard the upper butyl acetate layer, pour the aqueous layer back intothe separatory funnel and repeat the extraction two more times or until the butyl acetate layer is water-white. Return the ammoniacal, aqueous layer to the separatory funnel. Add 10 mL of citric acid solution, 15mL of EDTA-solution followed by 10 mL of carbamate solution. Swirl to mix and allow 15 minutes for thecopper-carbamatecomplextoform.Add by pipet 20 mL of n-butyl acetate, stopper the separatory funnel and shake for 2 minutes. Allow thelayers to separate for 2 minutes. Using a pH indicator strip, test a drop of the aqueous layer to verify that thepH is greater than 9. If not, repeat the analysis but add approximately 25 mL of ammonium hydroxide.Drain and discard the lower aqueous layer. To the yellow butyl acetate layer containing the copper complex,add 25 mL of 1-M hydrochloric acid, stopper and shake for 30 seconds. Allow the layers to separate forapproximately 1 minute, drain the lower acidic-aqucous layer and discard.Using the plastic powder funnel and a scoop-spatula-spoon, add approximately 5 g of sodium sulfate tothe sample extract. Stopper and shake for one minute to absorb all moisture from the organic phase. Brieflyclean the neck of each flask using a paper towel and decant the extract through the neck of the separatoryfunnel directly into a 20-mm spectrophotometric cell. Determine the net absorbance at 430 nm, using n-butyl acetate as the reference solution for the cxtracts and reagent blank. Determine the absorbance within30 minutes of the n-butyl acetate addition and avoid undue exposure to light. If the color is too intense, takea smaller sample volume and repeat the analysis. If a visual comparison is to be made, decant the extractinto a roundcuvette.

Determine the micrograms of copper per 2o mL from the spectrophotometric calibration curve or byvisual comparison to the previously prepared standards.CALCULATIONS

1000AB免费标准bzxz.net

Copper,μg/L=

where:

A=mass ofCu/20mLfrom calibrationcurve orfromcolor standards,μgB = volume of sodium hypochlorite plus volume of hydrochloric acid used for extraction, 25mL

C =volume ofaliquotof sodiumhypochlorite-acid extractused for analysis,20mLV=volumeofsample,typically,500mL1000=conversionfactor,μg/mLto μg/LWhen 5oo mL of sample is used and there are no deviations from the other specified volumes, theexpressionbecomes:

Copper, μg/L = 2.5 A

144-88

whereAisaspreviouslydefined

PRECAUTIONS

Keep all glassware scrupulously clean in order to avoid contamination from copper.Thebestresults areobtained when the glassware is reserved only for these analyses.When extracting the hydrocarbon with the hypochlorite-acid mixture, vent the funnel frequently. Do thisalso when scrubbing the ammoniacal solution with n-butyl acetate.PRECISION

Repeatability

Based on two tests performed by each of two analysts, on each of two days (8 tests), the within-laboratoryestimated standard deviation (esd) was calculated to be 3.27 at a copper concentration of 21 μg/L. Two testsperformed in one laboratory by different analysts on different days should not differ by more than 12.8(95%probability)atthestatedlevel.Reproducibility

There is insufficient data to calculate the reproducibility of the test atthis time.TIMEFORANALYSIS

The elapsed time and labor requirement for calibration and one analysis are identical, 6 hours. In groupsof 4 samples, the elapsed time and labor requirement are 8 hours.REFERENCE

ASTMMethodD1193,www.astm.orgFurman, N. Howell, Editor, Standard Methods of Chemical Analysis, D. Van Nostrand Co., Inc., (1962)Vol.1, 6th ed.,407

SUGGESTEDSUPPLIERS

Aldrich Chemical Co., 940 W. St. Paul Ave., Milwaukee, WI 53233J.T. Baker Chemical Co., 222 Red School Ln., Phillipsburg, NJ 08865Fisher Scientific Co., 711 Forbes Ave., Pittsburgh, PA 15219Sargent-Welch Scientific Co., 7300 N.Linder Ave., Skokie, IL 60077144-88

还剩1页未读,是否继续阅读?

此文档由标准图书馆分享于2018-03-10..

REF.SOLUTION:

n-BUTYLACETATE

20-mmcELL

μgcu/20ml

Figure

Typical Calibration Curve for Determinationof Copper in Gasoline and Naphtha40

144-88

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。