SN/T 2648-2010

基本信息

标准号: SN/T 2648-2010

中文名称:进出口食品中啶酰菌胺残留量的测定 气相色谱-质谱法

标准类别:商检行业标准(SN)

标准状态:现行

出版语种:简体中文

下载格式:.rar .pdf

下载大小:599KB

相关标签: 进出口 食品 中啶 酰菌胺 残留量 测定 相色谱 质谱法

标准分类号

关联标准

出版信息

相关单位信息

标准简介

SN/T 2648-2010 进出口食品中啶酰菌胺残留量的测定 气相色谱-质谱法

SN/T2648-2010

标准下载解压密码:www.bzxz.net

标准图片预览

标准内容

中华人民共和国出入境检验检疫行业标准SN/T2648—2010

进出口食品中啶酰菌胺残留量的测定气相色谱-质谱法

Determination of boscalid residues in food for import and export-GC-MSmethod

2010-11-01发布

中华人民共和国

国家质量监督检验检疫总局

2011-05-01实施

本标准按照GB/T1.1—2009给出的规则起草。本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国山东出人境检验检疫局,本标准主要起草人:王建华、郭翠、宫萍、王松、蔡发SN/T2648—2010

1范围

进出口食品中啶菌胺残留量的测定气相色谱-质谱法

本标准规定了食品中酰菌胺残留量的气相色谱-质谱检测方法SN/T2648—2010

本标准适用于菠菜、胡萝下、草莓、花生、板栗、茶叶、葱、鸡肉、鳕鱼和蜂密中啶酰菌胺残留量的检测和确证。

2方法提要

试样中啶酰菌胺用乙睛提取,经液/液分配和PSA固相萃取柱净化,用气相色谱-电子轰击源质谱测定,外标法定量。

3试剂和材料

除另有规定外,所用试剂均为分析纯,水为二次蒸馏水。3.1丙酮:农药残留级。

3.2乙睛:农药残留级。

3.3正已烷:农药残留级。

3.4正已烷饱和乙睛:取100mL正已烷,100mL乙睛于分液漏斗中,振荡混勾,取下层待用。3.5乙睛饱和正已烷:取100mL正已烷,100mL乙睛于分液漏斗中,振荡混勾,取上层待用。3.6氯化钠:650℃灼烧4h,置人干燥器中冷却,备用。3.7丙酮-正已烷(3+7.体积比):取300mL丙酮.加入700mL正已烷,摇匀备用。3.8啶酰菌胺标准物质(boscalid,CAS编号:188425-85-6,分子式:C1sH12C12N,O):纯度大于或等于98.0%。

3.9啶酰菌胺标准溶液:准确称取适量标准品用丙酮溶解并配制成浓度为1.0mg/mL的标准储备液根据需要再用不含啶酰菌胺的空白样品基质溶液稀释成适当浓度的标准工作溶液。保存于一18℃冰箱中。

3.10丙基乙二胺键合硅胶(PrimarySecondaryamine,PSA)固相萃取柱:500mg,3mL或相当者。4

仪器和设备

4.1气相色谱-质谱议:配有电子轰击源(EI)。4.2固相萃取装置。

4.3均质器,转速10000r/min。

4.4旋转蒸发器。

4.5氮气浓缩仪。

4.6具塞离心管:50mL、100mL。4.7浓缩瓶:50mL、100mL。

4.8分析天平:感量0.01g。

SN/T2648—2010

4.9分析天平:感量0.1mg。

5试样制备与保存

5.1试样制备

5.1.1粮谷和坚果

取有代表性样品量500g,全部磨碎并通过2.0mm圆孔筛。混匀,装人洁净的容器内,密闭,标明标记。

5.1.2水果和蔬菜

取有代表性样品500g,将其可食用部分切碎后(不可水洗),用食品捣碎机将样品加工成浆状。混匀,装人洁净的容器内,密闭,标明标记5.1.3肉和鱼

取有代表性样品500g,取可食部分充分搅碎均匀,装入洁净容器内作为试样。密闭,标明标记,5.1.4蜂蜜

取有代表性样品500g,对无结晶的蜂蜜样品将其搅拌均匀;对有结晶析出的蜂蜜样品,在密闭情况下,将样品瓶置于不超过60℃的水浴中温热,振荡,待样品全部融化后搅勾,迅速冷却至室温,在融化时应注意防止水分挥发。装入洁净的容器,密闭,标明标记。5.1.5茶叶

取有代表性样品500g,用磨碎机全部磨碎并通过2.0mm圆孔筛。混匀,装人洁净的洁净容器内密闭,标明标记。

5.2试样保存

粮谷和坚果类试样于0℃~4℃保存;其他类试样于一18℃以下冷冻保存。在制样的操作过程中应防止样品受到污染或发生残留物含量的变化。6测定步骤

6.1提取

称取10g试样(精确至0.01g)于100mL具塞离心管中,加入10mL水,准确加人40.0mL正已烷饱和乙睛(3.4),均质器提取2min(蜂蜜需加水10mL和乙睛剧烈振荡20min),再加人5g氯化钠.剧烈振荡10min,3000r/min离心10min,待净化。6.2净化

6.2.1液/液分配净化

取上层提取液20.0mL(菠菜、胡萝卜、草莓)或10.0mL(花生、鸡肉、葱、鳕鱼、蜂蜜、板栗和茶叶)转移至50mL具塞离心管中,加人10mL乙睛饱和正已烷(3.5),振摇3min,静置分层,弃去上层正已烷相,再用10mL乙睛饱和正已烷(3.5)重复操作一次,弃去正已烷相;下层乙睛相收集于100mL浓缩瓶中,于40℃水浴中浓缩至近1mL。2

6.2.2固相萃取(SPE)净化

SN/T2648—2010

用5mL内酮-正已烷(3.7)预淋洗PSA柱。将样液(6.2.1)倾入柱中,用10mL内酮-正已烷(3.7)洗脱,控制流速小于2mL/min。收集全部洗脱液于40℃水浴中浓缩至近干,氮气吹干。用丙酮-正已烷(3.7)溶解并定容至1.0mL,气相色谱-质谱仪测定。6.3测定

6.3.1气相色谱-质谱条件

气相色谱-质谱条件如下:

色谱柱:HP-5MS石英毛细管柱,30m×0.25mm(内径),膜厚0.25μm,或相当者;a)

色谱柱温度:初始温度为70℃,保持2min,以25℃/min程序升温至150℃,以15℃/min程序升温至200℃,再以10℃/min程序升温至280℃,保持10min;进样口温度:250℃;

色谱-质谱接口温度:280℃;

载气:氢气,纯度大于等于99.999%,恒流模式,1mL/min;进样量:1uL;

进样方式:无分流进样,0.65min后开阀;电离方式:电子轰击;

离子源温度:230℃;

四极杆温度:150℃:

测定方式:选择离子监测方式;1)

选择监测离子(m/z):定量140,定性112、167、342;m)溶剂延迟:4.0min。

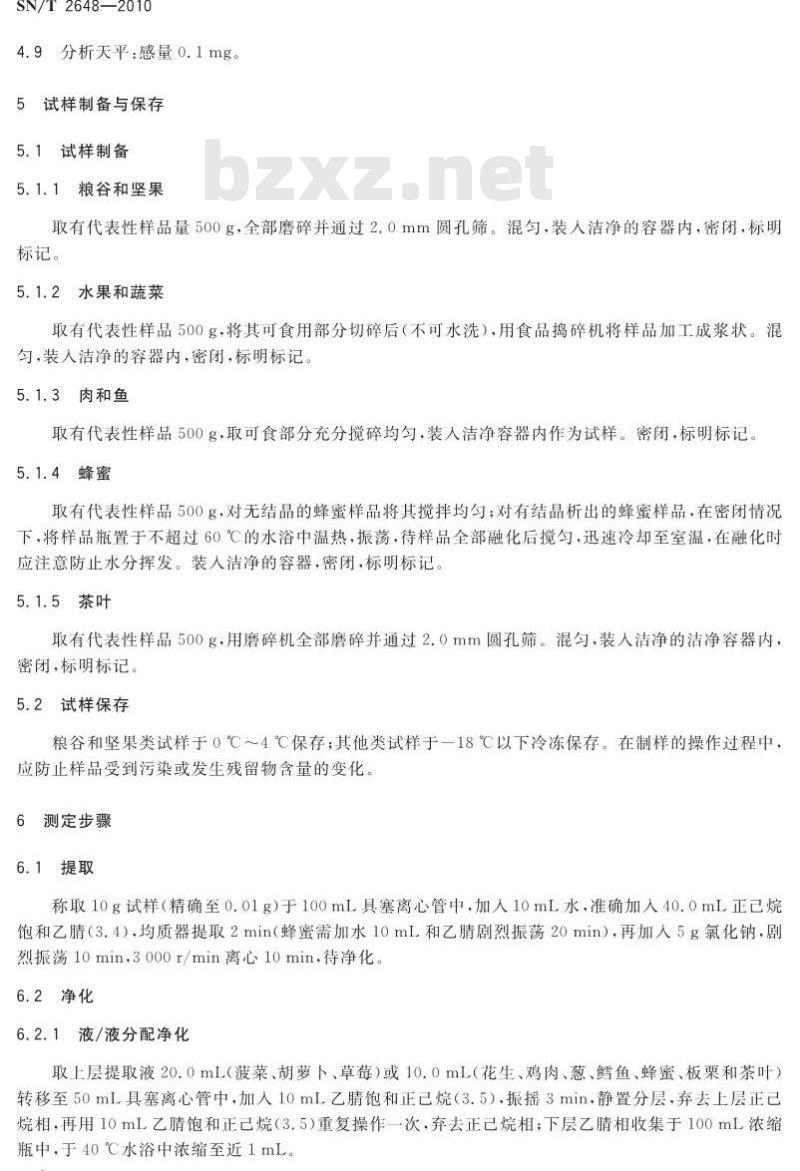

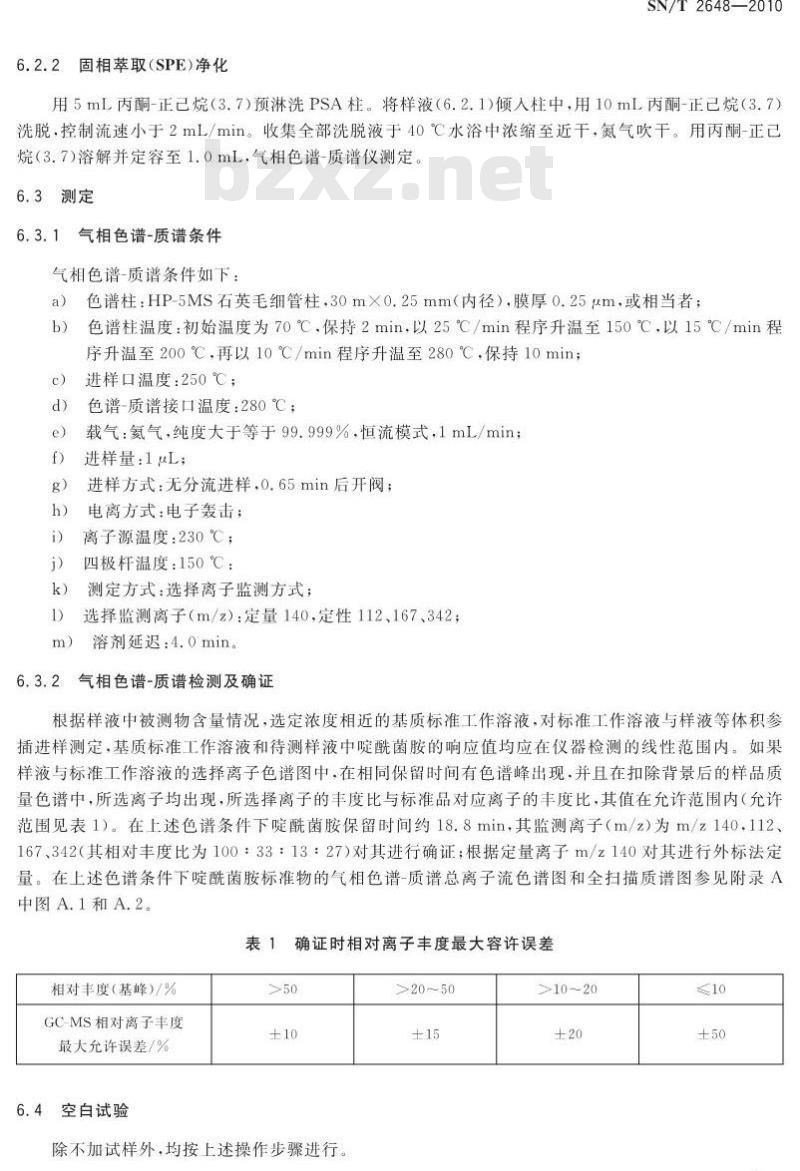

6.3.2气相色谱-质谱检测及确证根据样液中被测物含量情况,选定浓度相近的基质标准工作溶液,对标准工作溶液与样液等体积参插进样测定,基质标准工作溶液和待测样液中啶酰菌胺的响应值均应在仪器检测的线性范围内。如果样液与标准工作溶液的选择离子色谱图中,在相同保留时间有色谱峰出现:并自在扣除背景后的样品质量色谱中,所选离子均出现,所选择离子的丰度比与标准品对应离子的丰度比,其值在允许范围内(允许范围见表1)。在上述色谱条件下啶酰菌胺保留时间约18.8min,其监测离子(m/z)为m/z140,112、167、342(其相对丰度比为100:33:13:27)对其进行确证;根据定量离子m/z140对其进行外标法定量。在上述色谱条件下啶酰菌胺标准物的气相色谱-质谱总离子流色谱图和全扫描质谱图参见附录A中图A.1和A.2。

表1确证时相对离子丰度最大容许误差相对丰度(基峰)/%

GC-MS相对离子丰度

最大允许误差/%

6.4空白试验

除不加试样外,均按上述操作步骤进行。>20~50

>10~20

SN/T2648—2010

结果计算和表述

用色谱数据处理机或按式(1)计算试样中啶酰菌胺残留量:hXexV

式中:

试样中啶酰菌胺残留量,单位为毫克每千克(mg/kg);样液中啶酰菌胺的色谱峰高,单位为毫米(mm);标准工作液中啶酰菌胺的浓度,单位为微克每毫升(μg/mL);样液最终定容体积,单位为毫升(mL);标准工作液中啶酰菌胺的色谱峰高,单位为毫米(mm);最终样液所代表的试样质量,单位为克(g)。测定低限、回收率

测定低限

本方法的测定低限为0.01mg/kg

回收率

样品添加浓度及回收率范围的实验数据见表2。表2

胡萝下

添加浓度

样品添加浓度及回收率范围的实验数据回收率范围

90.0~110.0

97.5112.5

95.0~105.0

95.0~111.0

95.0~107.0

96.0~105.0

95.0~110.0

97.5~105.5

97.0~105.0

90.0~110.0

97.5~107.5

98.0~107.0

95.0~110.0

96.0~107.5

94.0~106.0

添加浓度

回收率范围

90.0~110.0

97.5~104.5

94,0~112.0

90.0~110.0

92.5~102.5

95.0~105.0

95.0~110.0

92.5~107.5免费标准bzxz.net

95.0~106.0

90.0~110.0

97.5~112.5

98.05~103.0

95.0~110.0

97.5~105.0

95.0112.0

附录A

(资料性附录)

啶酰菌胺标准物质的气相色谱-质谱总离子流色谱图及质谱图图A.1

啶酰菌胺标准物的气相色谱-质谱总离子流色谱图-T

啶酰菌胺标准物质的质谱图

SN/T2648—2010

aedaaae

SN/T2648—2010

Foreword

This standard was proposed by and is under the charge of the Certification and Accreditation AdminstrationofthePeople'sRepublicofChinaThis standard was drafted by the Shandong Entry-Exit Inspection and Quarantine Bureau of the People's Republic of China

This main drafters of this standard:Wang jianhuaGuocui、Gongping、Wangsong、CaifaSN/T2648—2010

Determinationofboscalidresiduesinfoodforimport and exportGc-MS methodScope

This standard specifies the method of sample preparation and determination of Boscalid residue infoodstuffsbygaschromatography-massspectrometry.This standard is applicable to the determination and confirmation of Boscalid residue in spinach,carrot,strawberry.peanut.chicken,scallion.ling.honey.chestnut and tea.2 Principle

Thetest sampleisextracted with acetonitrile,then the extract is partitioned withn-hexane beforecleaning upprocedure by passingthrougha PSA solid phase extraction(SPE)column.Residue is determined by GC-Ei-MS,and quantitated by external standard method.3Reagents andmaterials

All the reagents used should be analytically pure unless otherwise specified.\Water\ is redistilledwater.

Acetone:Pesticideresiduesgrade3.2 Acetonitrile:Pesticide residues grade.3.3n-Hexane:Pesticideresiduesgrade3.4

Saturated hexaneSaturatedwithacetonitrileSaturatedacetonitrileSaturatedwithhexane3.5

Sodiumchloride:Driedat650℃for4h,andstoredinasealedcontainer3.7

Acetone-n-Hexane(3+7,V/V):Dilute 300 mL acetone with n-Hexane to the volume of1000mL

SN/T2648—2010

Boscalidstandard(boscalid.CASNo.:188425-85-6.:C18Ht2C12N,O):Purity≥98.0%3.9

Standard stock solution:Accurately weigh appropriate amount of Boscalid standard anddissolve with a little volume of acetone followed by a further dilution to the final concentration of1.Omg/mL.Thendilutethestandard stock solutionwith matrix solutionto makestandard workingsolutionofrequiredconcentrationandstoredat-18℃.3.10PSASPEcolumns:500mg.3mL.cleanertorequivalent.4

Apparatusandequipment

Gaschromatographyequippedwithelectronimpactmassspectrometry4.1

Column Processor.

4.3Homogenizer:10000r/min.

4.4Rotary vacuumevaporator

4.5Nitrogenevaporator.

Centrifugetube,50mL100mLwithstopper4.7

Concentratingbottle:50mL,100mL4.8Analyticalbalance:accurateto0.01g.4.9Analyticalbalance:accurateto0.1mgPreparationandstorageof test sample5

5.1 Preparation of test sample5.1.1Cerealsand nut

Take approximately500gof representative sample.Grind withagrindertopassthrougha2.0mmround-hole sieve.Mix thoroughly and divide into two equal portions. Each portion is placed into aclean container,as test sample,sealed and labelled.8

5.1.2Fruits and vegetables

SN/T2648—2010

Takeapproximately5o0gof.representative sample(witoutwashbywater).The ediblepartsareblendedandhomogenized in a high speed blender.Divide into two equal portions.Each portion isplacedintoacleancontainerastestsamplesealedandlabeled.5.1.3Meatand fish

Take approximately500g of representative sample.Theedible partsare blended andhomogenized inahighspeedblender.Divideintotwo equalportions.Eachportion isplacedintoaclean containerasthetest sample.sealed and labeled.5.1.4Honey and honey productTake approximately 5oo g of representative sample.Homogenize the non-crystallization honey andthe crystallized honey in the sample bottle should be warmed under water bath at the temperature ofno more than 60C.Shake the bottle until the sample is completely dissolved.Sample should be ho-mogenizedandcooleddown toroomtemperaturerapidly.Dopreventtheevaporatingof waterdur-ingtheheatingprocedure.Thenplace intoaclean containeras thetest sample,sealed andlabeled.5.1.5Tea

Takeapproximately500gof representative sample.Grind andpass througha2.0mm round-holesieve.Mixthoroughlyandplace into aclean containerasthetest sample,sealed and labeled.5.2Storageoftestsample

The test samples of cereals and nut shall be stored at the range of o C ~4 ℃. The test samples offruitsandvegetablesshallbestoredbelow-18C.Duringsamplingandsamplepreparation.precau-tion shall betaken to avoid contaminationorany factors which may cause the change of residue con.tent.

6Procedure

6.1Extraction

Weigh 10 g (accurate to 0.01g)of the test sample into a 100 mL centrifuge tube equipped withastopper.And accuratelyadd10mLof water,40mLsaturatedacetonitrile(3.4)intotheflask.Extractfor2min inahighspeedhomogenizer.Add5gSodiumchloride(3.6),shakefor10min,centrifugefor10minat3000r/min.

SN/T2648—2010

6.2Cleaningup

6.2. 1Liquid /liquid partitionTransferthe20.0mL(spinach,carrot,strawberry)or10.0mL(peanut,chicken,scallion.ling.honeychestnut,teaandsauce)ofsupernatantintoa50mLcentrifugetubeadd10mLofsaturatedhexaneshakefor3min and place aside for separation.Discard the hexane phase.Repeat aboveprocedureand condense acetonitrile to nearly dryness by a rotary evaporator at 40 .Dissolve the residuewith1mLofacetone-hexane(3.7)forSPEpurification.6.2.2 SPE cleaning up

RinseaPSAcolumnwith5mLofacetone-hexane(3.7).Loadtheabovesolutiontocolumn,andelutethecolumnwith10mLofacetone-hexane(3.7).alleluatesaretransfered intoa50mLconcen-trate bottle and evaporated to drynessbya rotary evaporator at 4o .Dissolve the residuewith ac-etone-hexane(3.7)toexactvolumeof1.0mLfordeterminationbyGC-MS.6.3Determination

6.3.1Gc-MSoperatingconditiona)

Chromatographiccolumn:HP-5MSsilicacapillarycolumn30m×0.25mm(i.d.),0.25μmfilmthickness,and or equivalent;Columntemperature:70℃for2min.rampat25℃/minto150℃,thenincreaseat15℃/minto200℃,andthenincreaseat1o℃/minto280℃,holdfor10min;Injectortemperature:250℃

Interfacetemperature:280℃;

Carriergas:Helium.purity≥99.999%,constantflow:1mL/min;Injection volume:1μL;

InjectionmodeSplitless,openthevalveafter0.65min;Electricalionizationmode:El;lon source temperature:230℃;Quadropoletemperature:15o℃Selectedionmonitoringmode

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

进出口食品中啶酰菌胺残留量的测定气相色谱-质谱法

Determination of boscalid residues in food for import and export-GC-MSmethod

2010-11-01发布

中华人民共和国

国家质量监督检验检疫总局

2011-05-01实施

本标准按照GB/T1.1—2009给出的规则起草。本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国山东出人境检验检疫局,本标准主要起草人:王建华、郭翠、宫萍、王松、蔡发SN/T2648—2010

1范围

进出口食品中啶菌胺残留量的测定气相色谱-质谱法

本标准规定了食品中酰菌胺残留量的气相色谱-质谱检测方法SN/T2648—2010

本标准适用于菠菜、胡萝下、草莓、花生、板栗、茶叶、葱、鸡肉、鳕鱼和蜂密中啶酰菌胺残留量的检测和确证。

2方法提要

试样中啶酰菌胺用乙睛提取,经液/液分配和PSA固相萃取柱净化,用气相色谱-电子轰击源质谱测定,外标法定量。

3试剂和材料

除另有规定外,所用试剂均为分析纯,水为二次蒸馏水。3.1丙酮:农药残留级。

3.2乙睛:农药残留级。

3.3正已烷:农药残留级。

3.4正已烷饱和乙睛:取100mL正已烷,100mL乙睛于分液漏斗中,振荡混勾,取下层待用。3.5乙睛饱和正已烷:取100mL正已烷,100mL乙睛于分液漏斗中,振荡混勾,取上层待用。3.6氯化钠:650℃灼烧4h,置人干燥器中冷却,备用。3.7丙酮-正已烷(3+7.体积比):取300mL丙酮.加入700mL正已烷,摇匀备用。3.8啶酰菌胺标准物质(boscalid,CAS编号:188425-85-6,分子式:C1sH12C12N,O):纯度大于或等于98.0%。

3.9啶酰菌胺标准溶液:准确称取适量标准品用丙酮溶解并配制成浓度为1.0mg/mL的标准储备液根据需要再用不含啶酰菌胺的空白样品基质溶液稀释成适当浓度的标准工作溶液。保存于一18℃冰箱中。

3.10丙基乙二胺键合硅胶(PrimarySecondaryamine,PSA)固相萃取柱:500mg,3mL或相当者。4

仪器和设备

4.1气相色谱-质谱议:配有电子轰击源(EI)。4.2固相萃取装置。

4.3均质器,转速10000r/min。

4.4旋转蒸发器。

4.5氮气浓缩仪。

4.6具塞离心管:50mL、100mL。4.7浓缩瓶:50mL、100mL。

4.8分析天平:感量0.01g。

SN/T2648—2010

4.9分析天平:感量0.1mg。

5试样制备与保存

5.1试样制备

5.1.1粮谷和坚果

取有代表性样品量500g,全部磨碎并通过2.0mm圆孔筛。混匀,装人洁净的容器内,密闭,标明标记。

5.1.2水果和蔬菜

取有代表性样品500g,将其可食用部分切碎后(不可水洗),用食品捣碎机将样品加工成浆状。混匀,装人洁净的容器内,密闭,标明标记5.1.3肉和鱼

取有代表性样品500g,取可食部分充分搅碎均匀,装入洁净容器内作为试样。密闭,标明标记,5.1.4蜂蜜

取有代表性样品500g,对无结晶的蜂蜜样品将其搅拌均匀;对有结晶析出的蜂蜜样品,在密闭情况下,将样品瓶置于不超过60℃的水浴中温热,振荡,待样品全部融化后搅勾,迅速冷却至室温,在融化时应注意防止水分挥发。装入洁净的容器,密闭,标明标记。5.1.5茶叶

取有代表性样品500g,用磨碎机全部磨碎并通过2.0mm圆孔筛。混匀,装人洁净的洁净容器内密闭,标明标记。

5.2试样保存

粮谷和坚果类试样于0℃~4℃保存;其他类试样于一18℃以下冷冻保存。在制样的操作过程中应防止样品受到污染或发生残留物含量的变化。6测定步骤

6.1提取

称取10g试样(精确至0.01g)于100mL具塞离心管中,加入10mL水,准确加人40.0mL正已烷饱和乙睛(3.4),均质器提取2min(蜂蜜需加水10mL和乙睛剧烈振荡20min),再加人5g氯化钠.剧烈振荡10min,3000r/min离心10min,待净化。6.2净化

6.2.1液/液分配净化

取上层提取液20.0mL(菠菜、胡萝卜、草莓)或10.0mL(花生、鸡肉、葱、鳕鱼、蜂蜜、板栗和茶叶)转移至50mL具塞离心管中,加人10mL乙睛饱和正已烷(3.5),振摇3min,静置分层,弃去上层正已烷相,再用10mL乙睛饱和正已烷(3.5)重复操作一次,弃去正已烷相;下层乙睛相收集于100mL浓缩瓶中,于40℃水浴中浓缩至近1mL。2

6.2.2固相萃取(SPE)净化

SN/T2648—2010

用5mL内酮-正已烷(3.7)预淋洗PSA柱。将样液(6.2.1)倾入柱中,用10mL内酮-正已烷(3.7)洗脱,控制流速小于2mL/min。收集全部洗脱液于40℃水浴中浓缩至近干,氮气吹干。用丙酮-正已烷(3.7)溶解并定容至1.0mL,气相色谱-质谱仪测定。6.3测定

6.3.1气相色谱-质谱条件

气相色谱-质谱条件如下:

色谱柱:HP-5MS石英毛细管柱,30m×0.25mm(内径),膜厚0.25μm,或相当者;a)

色谱柱温度:初始温度为70℃,保持2min,以25℃/min程序升温至150℃,以15℃/min程序升温至200℃,再以10℃/min程序升温至280℃,保持10min;进样口温度:250℃;

色谱-质谱接口温度:280℃;

载气:氢气,纯度大于等于99.999%,恒流模式,1mL/min;进样量:1uL;

进样方式:无分流进样,0.65min后开阀;电离方式:电子轰击;

离子源温度:230℃;

四极杆温度:150℃:

测定方式:选择离子监测方式;1)

选择监测离子(m/z):定量140,定性112、167、342;m)溶剂延迟:4.0min。

6.3.2气相色谱-质谱检测及确证根据样液中被测物含量情况,选定浓度相近的基质标准工作溶液,对标准工作溶液与样液等体积参插进样测定,基质标准工作溶液和待测样液中啶酰菌胺的响应值均应在仪器检测的线性范围内。如果样液与标准工作溶液的选择离子色谱图中,在相同保留时间有色谱峰出现:并自在扣除背景后的样品质量色谱中,所选离子均出现,所选择离子的丰度比与标准品对应离子的丰度比,其值在允许范围内(允许范围见表1)。在上述色谱条件下啶酰菌胺保留时间约18.8min,其监测离子(m/z)为m/z140,112、167、342(其相对丰度比为100:33:13:27)对其进行确证;根据定量离子m/z140对其进行外标法定量。在上述色谱条件下啶酰菌胺标准物的气相色谱-质谱总离子流色谱图和全扫描质谱图参见附录A中图A.1和A.2。

表1确证时相对离子丰度最大容许误差相对丰度(基峰)/%

GC-MS相对离子丰度

最大允许误差/%

6.4空白试验

除不加试样外,均按上述操作步骤进行。>20~50

>10~20

SN/T2648—2010

结果计算和表述

用色谱数据处理机或按式(1)计算试样中啶酰菌胺残留量:hXexV

式中:

试样中啶酰菌胺残留量,单位为毫克每千克(mg/kg);样液中啶酰菌胺的色谱峰高,单位为毫米(mm);标准工作液中啶酰菌胺的浓度,单位为微克每毫升(μg/mL);样液最终定容体积,单位为毫升(mL);标准工作液中啶酰菌胺的色谱峰高,单位为毫米(mm);最终样液所代表的试样质量,单位为克(g)。测定低限、回收率

测定低限

本方法的测定低限为0.01mg/kg

回收率

样品添加浓度及回收率范围的实验数据见表2。表2

胡萝下

添加浓度

样品添加浓度及回收率范围的实验数据回收率范围

90.0~110.0

97.5112.5

95.0~105.0

95.0~111.0

95.0~107.0

96.0~105.0

95.0~110.0

97.5~105.5

97.0~105.0

90.0~110.0

97.5~107.5

98.0~107.0

95.0~110.0

96.0~107.5

94.0~106.0

添加浓度

回收率范围

90.0~110.0

97.5~104.5

94,0~112.0

90.0~110.0

92.5~102.5

95.0~105.0

95.0~110.0

92.5~107.5免费标准bzxz.net

95.0~106.0

90.0~110.0

97.5~112.5

98.05~103.0

95.0~110.0

97.5~105.0

95.0112.0

附录A

(资料性附录)

啶酰菌胺标准物质的气相色谱-质谱总离子流色谱图及质谱图图A.1

啶酰菌胺标准物的气相色谱-质谱总离子流色谱图-T

啶酰菌胺标准物质的质谱图

SN/T2648—2010

aedaaae

SN/T2648—2010

Foreword

This standard was proposed by and is under the charge of the Certification and Accreditation AdminstrationofthePeople'sRepublicofChinaThis standard was drafted by the Shandong Entry-Exit Inspection and Quarantine Bureau of the People's Republic of China

This main drafters of this standard:Wang jianhuaGuocui、Gongping、Wangsong、CaifaSN/T2648—2010

Determinationofboscalidresiduesinfoodforimport and exportGc-MS methodScope

This standard specifies the method of sample preparation and determination of Boscalid residue infoodstuffsbygaschromatography-massspectrometry.This standard is applicable to the determination and confirmation of Boscalid residue in spinach,carrot,strawberry.peanut.chicken,scallion.ling.honey.chestnut and tea.2 Principle

Thetest sampleisextracted with acetonitrile,then the extract is partitioned withn-hexane beforecleaning upprocedure by passingthrougha PSA solid phase extraction(SPE)column.Residue is determined by GC-Ei-MS,and quantitated by external standard method.3Reagents andmaterials

All the reagents used should be analytically pure unless otherwise specified.\Water\ is redistilledwater.

Acetone:Pesticideresiduesgrade3.2 Acetonitrile:Pesticide residues grade.3.3n-Hexane:Pesticideresiduesgrade3.4

Saturated hexaneSaturatedwithacetonitrileSaturatedacetonitrileSaturatedwithhexane3.5

Sodiumchloride:Driedat650℃for4h,andstoredinasealedcontainer3.7

Acetone-n-Hexane(3+7,V/V):Dilute 300 mL acetone with n-Hexane to the volume of1000mL

SN/T2648—2010

Boscalidstandard(boscalid.CASNo.:188425-85-6.:C18Ht2C12N,O):Purity≥98.0%3.9

Standard stock solution:Accurately weigh appropriate amount of Boscalid standard anddissolve with a little volume of acetone followed by a further dilution to the final concentration of1.Omg/mL.Thendilutethestandard stock solutionwith matrix solutionto makestandard workingsolutionofrequiredconcentrationandstoredat-18℃.3.10PSASPEcolumns:500mg.3mL.cleanertorequivalent.4

Apparatusandequipment

Gaschromatographyequippedwithelectronimpactmassspectrometry4.1

Column Processor.

4.3Homogenizer:10000r/min.

4.4Rotary vacuumevaporator

4.5Nitrogenevaporator.

Centrifugetube,50mL100mLwithstopper4.7

Concentratingbottle:50mL,100mL4.8Analyticalbalance:accurateto0.01g.4.9Analyticalbalance:accurateto0.1mgPreparationandstorageof test sample5

5.1 Preparation of test sample5.1.1Cerealsand nut

Take approximately500gof representative sample.Grind withagrindertopassthrougha2.0mmround-hole sieve.Mix thoroughly and divide into two equal portions. Each portion is placed into aclean container,as test sample,sealed and labelled.8

5.1.2Fruits and vegetables

SN/T2648—2010

Takeapproximately5o0gof.representative sample(witoutwashbywater).The ediblepartsareblendedandhomogenized in a high speed blender.Divide into two equal portions.Each portion isplacedintoacleancontainerastestsamplesealedandlabeled.5.1.3Meatand fish

Take approximately500g of representative sample.Theedible partsare blended andhomogenized inahighspeedblender.Divideintotwo equalportions.Eachportion isplacedintoaclean containerasthetest sample.sealed and labeled.5.1.4Honey and honey productTake approximately 5oo g of representative sample.Homogenize the non-crystallization honey andthe crystallized honey in the sample bottle should be warmed under water bath at the temperature ofno more than 60C.Shake the bottle until the sample is completely dissolved.Sample should be ho-mogenizedandcooleddown toroomtemperaturerapidly.Dopreventtheevaporatingof waterdur-ingtheheatingprocedure.Thenplace intoaclean containeras thetest sample,sealed andlabeled.5.1.5Tea

Takeapproximately500gof representative sample.Grind andpass througha2.0mm round-holesieve.Mixthoroughlyandplace into aclean containerasthetest sample,sealed and labeled.5.2Storageoftestsample

The test samples of cereals and nut shall be stored at the range of o C ~4 ℃. The test samples offruitsandvegetablesshallbestoredbelow-18C.Duringsamplingandsamplepreparation.precau-tion shall betaken to avoid contaminationorany factors which may cause the change of residue con.tent.

6Procedure

6.1Extraction

Weigh 10 g (accurate to 0.01g)of the test sample into a 100 mL centrifuge tube equipped withastopper.And accuratelyadd10mLof water,40mLsaturatedacetonitrile(3.4)intotheflask.Extractfor2min inahighspeedhomogenizer.Add5gSodiumchloride(3.6),shakefor10min,centrifugefor10minat3000r/min.

SN/T2648—2010

6.2Cleaningup

6.2. 1Liquid /liquid partitionTransferthe20.0mL(spinach,carrot,strawberry)or10.0mL(peanut,chicken,scallion.ling.honeychestnut,teaandsauce)ofsupernatantintoa50mLcentrifugetubeadd10mLofsaturatedhexaneshakefor3min and place aside for separation.Discard the hexane phase.Repeat aboveprocedureand condense acetonitrile to nearly dryness by a rotary evaporator at 40 .Dissolve the residuewith1mLofacetone-hexane(3.7)forSPEpurification.6.2.2 SPE cleaning up

RinseaPSAcolumnwith5mLofacetone-hexane(3.7).Loadtheabovesolutiontocolumn,andelutethecolumnwith10mLofacetone-hexane(3.7).alleluatesaretransfered intoa50mLconcen-trate bottle and evaporated to drynessbya rotary evaporator at 4o .Dissolve the residuewith ac-etone-hexane(3.7)toexactvolumeof1.0mLfordeterminationbyGC-MS.6.3Determination

6.3.1Gc-MSoperatingconditiona)

Chromatographiccolumn:HP-5MSsilicacapillarycolumn30m×0.25mm(i.d.),0.25μmfilmthickness,and or equivalent;Columntemperature:70℃for2min.rampat25℃/minto150℃,thenincreaseat15℃/minto200℃,andthenincreaseat1o℃/minto280℃,holdfor10min;Injectortemperature:250℃

Interfacetemperature:280℃;

Carriergas:Helium.purity≥99.999%,constantflow:1mL/min;Injection volume:1μL;

InjectionmodeSplitless,openthevalveafter0.65min;Electricalionizationmode:El;lon source temperature:230℃;Quadropoletemperature:15o℃Selectedionmonitoringmode

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。