SN 0599-1996

基本信息

标准号: SN 0599-1996

中文名称:出口水果中速灭磷残留量检验方法

标准类别:商检行业标准(SN)

标准状态:现行

出版语种:简体中文

下载格式:.zip .pdf

下载大小:2845050

标准分类号

关联标准

出版信息

相关单位信息

标准简介

SN 0599-1996.Method for the determination of mevinphos residues in fruits for export.

1范围

SN 0599规定了出口水果中速灭磷残留量检验的抽样、制样和气相色谱测定方法。

SN 0599适用于出口苹果中速灭磷残留量的检验。

21曲样和制样

2.1检验批

以不超过1500件为一检验批。

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。

2.2抽样数量

批量,件 最低抽样数,件

1~25 1

26~100 5

101~250 10

251~1500 15

2.3抽样方法

按2.2规定的抽样件数随机抽职,逐件开启。每件至少职500为原始样品,原始样品总量不得少于2kge加封后,标明标记,及时送实验室。

2.4试样制备

将所取原始样品缩分出1kg,职可食部分,经组织捣碎机捣碎,均分成两份,装入洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于-18℃以下冷冻保存。

注:在抽样和制样的操作过程中,必须防止样品受到污染或发生残留物含量的变化。

3测定方法

3.1方法提要

试样经丙酮提职,提取液经用二氯甲烷和水进行液液分配,使待测农残进入二氯甲烷层。二氯甲烷层再经氧化铝和活性炭净化,浓缩,定容后,用配有火焰光度检测器的气相色谱仪测定,外标法定量。

3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为重蒸馏水。

1范围

SN 0599规定了出口水果中速灭磷残留量检验的抽样、制样和气相色谱测定方法。

SN 0599适用于出口苹果中速灭磷残留量的检验。

21曲样和制样

2.1检验批

以不超过1500件为一检验批。

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。

2.2抽样数量

批量,件 最低抽样数,件

1~25 1

26~100 5

101~250 10

251~1500 15

2.3抽样方法

按2.2规定的抽样件数随机抽职,逐件开启。每件至少职500为原始样品,原始样品总量不得少于2kge加封后,标明标记,及时送实验室。

2.4试样制备

将所取原始样品缩分出1kg,职可食部分,经组织捣碎机捣碎,均分成两份,装入洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于-18℃以下冷冻保存。

注:在抽样和制样的操作过程中,必须防止样品受到污染或发生残留物含量的变化。

3测定方法

3.1方法提要

试样经丙酮提职,提取液经用二氯甲烷和水进行液液分配,使待测农残进入二氯甲烷层。二氯甲烷层再经氧化铝和活性炭净化,浓缩,定容后,用配有火焰光度检测器的气相色谱仪测定,外标法定量。

3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为重蒸馏水。

标准图片预览

标准内容

中华人民共和国进出口商品检验行业标准SN0599-1996

出口水果中速灭磷残留量检验方法Methodforthedetermination ofmevinphosresiduesinfruitsforexport1996-11-15发布

1997-05-01实施

中华人民共和国国家进出口商品检验局发布SN0599-1996

本标准是根据GB/T1.1一1993≤标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》进行编写的。其中测定方法是参考国内外有关文献,经研究、改进和验证后制定的。本标准同时制定了抽样和制样方法。测定低限是根据国际上对水果中速灭磷的最高限量和测定方法的灵敏度而制定的。本标准的附录A是提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准起草单位:中华人民共和国辽宁进出口商品检验局和沈阳农业大学。本标准主要起草人:宫英姿、牛森、周艳明、宋文斌。本标准系首次发布的行业标准。1范围

中华人民共和国进出口商品检验行业标准出口水果中速灭磷残留量检验方法Method for the determination ofmevinphos residues in fruits for exportSN0599-1996

本标准规定了出口水果中速灭磷残留量检验的抽样、制样和气相色谱测定方法。本标准适用于出口苹果中速灭磷残留量的检验。2抽样和制样

2.1检验批

以不超过1500件为一检验批,

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

批量,件

101~250

251~1500

2.3抽样方法

最低抽样数,件

按2.2规定的抽样件数随机抽取,逐件开启。每件至少取500g作为原始样品,原始样品总量不得少于2kg。加封后,标明标记,及时送实验室。2.4试样制备

将所取原始样品缩分出1kg,取可食部分,经组织据碎机揭碎,均分成两份,装入洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于一18℃以下冷冻保存。注:在抽样和制样的操作过中,必须防止样品受到污或发生残留物含量的变化。3测定方法

3.1方法提要

试样经丙酮提取,提取液经用二氯甲烷和水进行液液分配,使待测农残进入二氟甲烷层。二氟甲烷层再经氧化铝和活性炭净化,浓缩,定容后,用配有火焰光度检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为重蒸馏水。3.2.1丙酮。

3.2.2二氯甲烷,

中华人民共和国国家进出口商品检验局1996-11-15批准1997-05-01实施

SN0599-1996

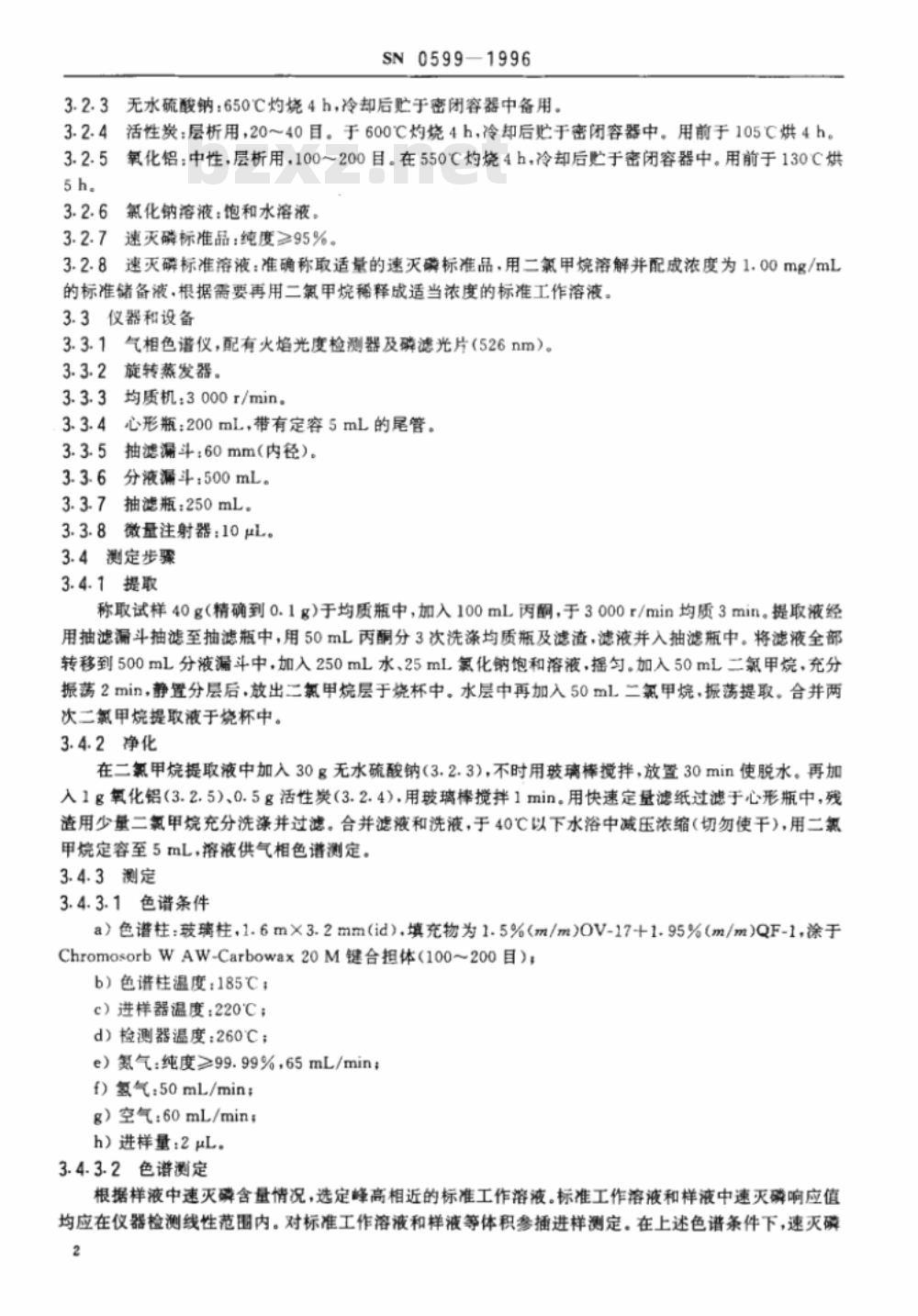

3.2.3无水硫酸钠:650℃灼烧4h,冷却后贮于密闭容器中备用。3.2.4活性炭:层析用,20~40目。于600℃灼烧4h,冷却后贮于密闭容器中。用前于105C烘4h。3.2.5氧化铝:中性,层析用,100~200目。在550℃C灼烧4h,冷却后贮于密闭容器中。用前于130℃烘5h。

氟化钠溶液:饱和水溶液。

3.2.7速灭磷标准品:纯度≥95%。3.2.8速灭磷标准溶液:准确称取适量的速灭磷标准品,用二氟甲烷溶解并配成浓度为1.00mg/mL的标准储备液,根据需要再用二氟甲烷稀释成适当浓度的标准工作溶液。3.3仅器和设备

3.3.1气相色谱仪,配有火焰光度检测器及磷滤光片(526nm)。3.3.2旋转蒸发器。

均质机:3000r/min。

心形瓶:200mL,带有定容5mL的尾管。抽滤漏斗:60mm(内径)

分液漏斗:500mL。

3.3.7抽滤瓶:250mL。

3.3.8微量注射器:10μL。

3.4测定步骤

3.4.1提取

称取试样40g(精确到0.1g)于均质瓶中,加入100mL丙酮,于3000r/min均质3min。提取液经用抽滤漏斗抽滤至抽滤瓶中,用50mL丙酮分3次洗涤均质瓶及滤渣,滤液并入抽滤瓶中。将滤液全部转移到500mL分液漏斗中,加入250mL水、25mL氯化钠饱和溶液,摇匀。加入50mL二氯甲烷,充分振荡2min,静置分层后,放出二氯甲烷层于烧杯中。水层中再加入50mL二氟甲烷,振荡提取。合并两次二氯甲烷提取液于烧杯中。

3.4.2净化

在二氯甲烷提取液中加入30g无水硫酸钠(3.2.3),不时用玻璃棒搅拌,放置30min使脱水。再加入1g氧化铝(3.2.5)、0.5g活性炭(3.2.4).用玻璃棒搅拌1min。用快速定量滤纸过滤于心形瓶中,残渣用少量二氯甲烷充分洗涤并过滤。合并滤液和洗液,于40℃以下水浴中减压浓缩(切勿使干),用二氟甲烧定容至5mL,溶液供气相色谱测定。3.4.3测定

3.4.3.1色谱条件

a)色谱柱:玻璃柱,1.6m×3.2mm(id).填充物为1.5%(m/m)0V-17+1.95%(m/m)QF-1涂于ChromosorbWAW-Carbowax2oM键合担体(100~200目);b)色谱柱温度:185℃;

c)进样器温度:220℃C;

d)检测器温度:260C;

e)氮气:纯度≥99.99%,65mL/minf)氢气:50mL/min;

g)空气:60mL/min;

h)进样量:2μL,

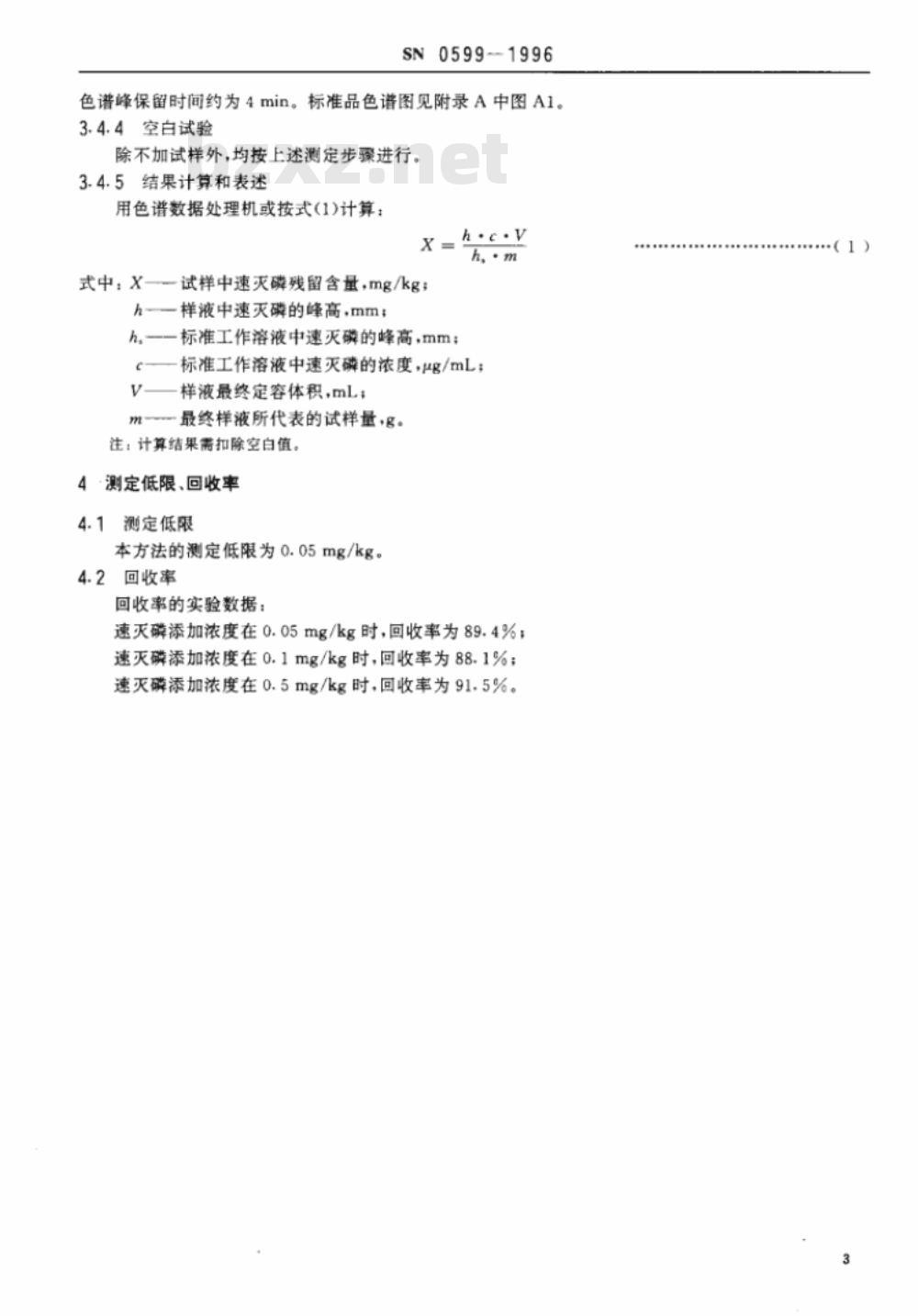

3.4.3.2色谱测定

根据样液中速灭磷含量情况,选定峰高相近的标准工作溶液。标准工作溶液和样液中速灭磷响应值均应在仪器检测线性范围内。对标准工作溶液和样液等体积参插进样测定。在上述色谱条件下,速灭碳2

SN0599-1996

色谱峰保留时间约为4min。标准品色谱图见附录A中图A1。3.4.4空白试验

除不加试样外,均按上述测定步骤进行。3.4.5结果计算和表述

用色谱数据处理机或按式(1)计算:h.c.y

式中:X—试样中速灭磷残留含量,mg/kg;h-样液中速灭磷的峰高,mm;

h,一-标准工作溶液中速灭磷的峰高,mm;一标准工作溶液中速灭磷的浓度,g/mL;V—样液最终定容体积,mL;

m-最终样液所代表的试样量.g。注:计算结果需扣除空白值。

4·测定低限、回收率

测定低限

本方法的测定低限为0.05mg/kg。4.2回收率

回收率的实验数据:

速灭磷添加浓度在0.05mg/kg时,回收率为89.4%;速灭磷添加浓度在0.1mg/kg时,回收率为88.1%;速灭磷添加浓度在0.5mg/kg时,回收率为91.5%。(1)

SN0599-1996

附录A

(提示的附录)

标准品气相色谱图

速灭磷标准品气相色谱图

SN05991996

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1-1993 \Directivesfor the work of standardization--Unit l:Drafting and presentation of standards-Part 1:General rulesfor drafting standards” and SN/T 0001-1995\General rules for drafting the standard methods for thedetermination of pesticide,veterinary drug residues and biotoxins in commodities for export.\ Themethods of determination of this standard was drafted by referring to relevant domestic and foreign lit-eratures through research,modification and verification. In addition,methods of sampling and samplepreparation are also specified in this standard.The limit of determination in this standard is defined on the basis of the current internationalmaximum limit for mevinphos residues in fruits and the sensitivity of the method.Annex Aof this standard is an informative annex.This standard was proposed by and is under the charge of the State Administration of Import andExport commodity Inspection of the People's Republic of China.This standard was drafted by the Liaoning Import and Export Commodity Inspection Bureau ofthe People's Republic of China and Shenyang Agriculture University.The main drafters of this standard are Gong Yingzi,Nu Shen,Zhou Yanming,Song Wenbin.This standard is a professional standard promulgated for thefirst time.Note: This English version,a translation from the Chinese text,is solely for guidance.Professional Standard of the People's Republic of ChinaforImportandExportCommodityInspectionSN0599-1996

Method for the determination ofmevinphosresiduesinfruitsforexport1Scope

This standard specifies the methods of samplingsample preparation and determination of mevinphos residues by gas chromatoqraphy in fruits for export.This standard is applicable to the determination of mevinphos residues in applefor exportSampling and sample preparation2

2.1Inspectionlot

Thequantityof aninspectionlotshouldnotbemorethan15oopackages.The characteristics of the cargo within the same inpection lot,such as packing,mark,origin,gradeand specification.should be the same.2.2Quantityof sampletaken

Numberofpackagesin

each inspection lot

26-100

101-250

251-1500

2.3 Sampling Procedure

Minimum number of

packages to be taken

A number of packages specified in 2.2 are taken at random and opened one by one.The sampleweight taken as the primary sample from each package should be at least 500 grams. The total weightof all primary samples should not be less than 2kg,which shall be sealed,labeled and sent to laboratoryin time.

2.4Preparationoftestsample

The combined primary sample is reduced to 1 kg,the edible portions are blended in a blender,andthen divided into two equal portions. Each portion is placed in a clean container as the test sample,which is sealed and labeled.2.5 Storageoftest sample

Thetestsamplesshouldbestoredbelow-18C.NoteIn the courseofsampling and samplepreparationprecautionmustbetaken to avoidthe contaminationoranyfactors which msy cause the change of residue content.ApprovedbytheStateAdministration ofImport and ExportCommodityInspection ofthePeople'sRepublicofChinaonNov.15,19966

ImplementedfromMay1.1997

3Mthodof determination

3.1Principle

SN0599-1996

The mevinphos residues in test sample are extracted with acetone, The extract is partitioned witha mixture of dichloromethane and water and the dichloromethane solution is cleand up with aluminaand charcoal.Then the solution is concentrated to a definite volume and analyzed by GC with flamephotometric detector,using external standard method.3.2Reagents and materials

Unless otherwise specified,all reagents should be analytically pure,\water\ is redistilled water.3.2.1Acetone.

3.2.2 Dichloromethane.

3.2.3Anhydrous sodium sulfate:Ignite at 650C for 4h,and keep in a desiccator.3.2.4Activated charcoal;For chromatographic use,2040mesh.Ignite at 600C for4hand store ina desiccator.Heat at 105 C for 4 h before use.3.2.5Alumina:Neutral,for chromatographic use,100-200mesh.Ignite at 550C for 4 h and storein a desiccator.Heat at 130C for 5 h before use.3.2.6Sodiumchloride solutionsaturated aqueous solution.3.2.7MevinphosstandardPurity≥95%.3.2.8 Mevinphos standard sodution:Accurately weigh a suitable amount of mevinphos standard,dis.solve in dichloromethane and prepare a solution of 1.O0 mg/mL in concentration as the standard stocksolution.Accordingto the requirement,dilute withdichloromethane to prepare a standardworking solution ofappropriateconcentration.3.3Apparatusand equipment

3.3.1Chromatograph;Equipped with flame photometric detector and phosphorous filter (526 nm).3.3.2 Rotary evaporator.

3.3.3Homogenizer3000or/min.

3.3.4Heart-shaped bottle;200mL,with5mLgraduated tip.3.3.5此内容来自标准下载网

Suctionfiliterfunnel:60mm(id).3.3.6

Separatoryfunnel:500mL.

Suctionflask:250mL

3.3.8Micro-syringe:10 μL.

3.4Procedure

3.4.1Extraction

Weigh ca 40 g of the test sample(accurate to 0.1 g) into a homogenizing bottle.Add 100 mL ofacetone and homogenize for 3min at 3 O00 r/min.Filter by suction the extract with a suction filter fun-nel into a suction flask,rinse the homogenizing bottle and the residue for several times with 50 mL ofacetone in total and filter.Combine the filtrates and the rinsings. Tranfer the filtrate into a 500-mLseparatory funnel,add 250 mL of water and 25 mL of saturated sodium chloride soiution and shake.Add 50 mL of dichloromethane and shake vigorously for 2 min. Let stand for separation. Drain thedichloromethane layer into a beaker.Re-extract the aqueous phase with 50 mL of dichloromethane asabove.Combinethedichloromethaneextracts in thebeaker.3.4.2Cleanup

Add 30 g of anhydrous sodium sulfate (3. 2. 3) into the dichloromethane extract. Let stand for 307

SN0599-1996

min with occasionally stirring with a glass rod to remove the water.Add 1 g of alumina (3. 2.5) and0.5 g of activated charcoal (3.2.4),and stir for 1 min.Filter the dichloromethane layer through high-speed quantitative filter paper into a heart shaped bottle,and wash the residue for several times withsamll amount of dichloromethane and filter. Combine the washings with the filtrates. The solution isconcentrated (never to dryness) in a 4o C water-bath under reduced pressure,and exactly diluted to 5mL with dichioromethane. The solution is used for chromatographic determination.3.4.3Determination

3.4.3.1 GC operating conditiona)Column:Glass1.6mX3.2mm(id).packedwith1.5%(m/m)0V-17+1.95%(m/m)QF-1onChromosorbWAW-Carbowax20Mcrosslinkedphase(100-200mesh);b)Column temperature:185C;

c)Injectionporttemperature:220Cd)Detector temperature:260'C;e)Nitrogen:Purity≥99.99%,65mL/min;f)Hydrogen:50mL/min;

g)Air60mL/min

3.4.3.2GC determination

According ro the approximate concentration of mevinphos in the sample solution,select the stan-dard working solution with similar peak height to that of sample solution, The responses of mevinphosin the standard solution and sample solution should be in the linear range of the instrumental detec-tion. The standard working solution should be injected in-between the injections of sample solution ofequal volume.Under the above chromatographic condition.the retention time of mevinphos is about 4min.For chromatogram of the standard,see fig.Al in annex A.3.4.4Blank test

The operation of the blank test is the same as that described in the method of determination butwithout addition of sample.

3.4.5Calculation and expression of result.The calculation of result is carried out by GC data processor or according to formula (1):h.c·V

X--the residue contentofmevinphos in test samplemg/kg;hthepeakheightofmevinphos inthesamplesolution.mm;h,the peak height of mevinphos in the standard working solution,mm;C-the concentration of mevinphos in the standard working solution,μg/mL;V-the final volume of sample solution,mL;mthe corresponding mass of test sample in the final sample solutiongNote: The blank value should be subttacted from the above result of calculstion.4Limit of determination and recovery4.1Limit ofdetermination

The limit of determination of this method is 0. 05 mg/kg.4.2Recovery

SN0599-1996

According to the experimental data,the fortifying concentrations of mevinphos and their correspondingrecoveriesare:

0.05mg/kg,therecovery89.4%;

0.1mg/kg,the recovery88.1%

0.5mg/kg,the recovery91.5%.

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

出口水果中速灭磷残留量检验方法Methodforthedetermination ofmevinphosresiduesinfruitsforexport1996-11-15发布

1997-05-01实施

中华人民共和国国家进出口商品检验局发布SN0599-1996

本标准是根据GB/T1.1一1993≤标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》进行编写的。其中测定方法是参考国内外有关文献,经研究、改进和验证后制定的。本标准同时制定了抽样和制样方法。测定低限是根据国际上对水果中速灭磷的最高限量和测定方法的灵敏度而制定的。本标准的附录A是提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准起草单位:中华人民共和国辽宁进出口商品检验局和沈阳农业大学。本标准主要起草人:宫英姿、牛森、周艳明、宋文斌。本标准系首次发布的行业标准。1范围

中华人民共和国进出口商品检验行业标准出口水果中速灭磷残留量检验方法Method for the determination ofmevinphos residues in fruits for exportSN0599-1996

本标准规定了出口水果中速灭磷残留量检验的抽样、制样和气相色谱测定方法。本标准适用于出口苹果中速灭磷残留量的检验。2抽样和制样

2.1检验批

以不超过1500件为一检验批,

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

批量,件

101~250

251~1500

2.3抽样方法

最低抽样数,件

按2.2规定的抽样件数随机抽取,逐件开启。每件至少取500g作为原始样品,原始样品总量不得少于2kg。加封后,标明标记,及时送实验室。2.4试样制备

将所取原始样品缩分出1kg,取可食部分,经组织据碎机揭碎,均分成两份,装入洁净容器内,作为试样。密封,并标明标记。

2.5试样保存

将试样于一18℃以下冷冻保存。注:在抽样和制样的操作过中,必须防止样品受到污或发生残留物含量的变化。3测定方法

3.1方法提要

试样经丙酮提取,提取液经用二氯甲烷和水进行液液分配,使待测农残进入二氟甲烷层。二氟甲烷层再经氧化铝和活性炭净化,浓缩,定容后,用配有火焰光度检测器的气相色谱仪测定,外标法定量。3.2试剂和材料

除另有规定外,所用试剂均为分析纯,水为重蒸馏水。3.2.1丙酮。

3.2.2二氯甲烷,

中华人民共和国国家进出口商品检验局1996-11-15批准1997-05-01实施

SN0599-1996

3.2.3无水硫酸钠:650℃灼烧4h,冷却后贮于密闭容器中备用。3.2.4活性炭:层析用,20~40目。于600℃灼烧4h,冷却后贮于密闭容器中。用前于105C烘4h。3.2.5氧化铝:中性,层析用,100~200目。在550℃C灼烧4h,冷却后贮于密闭容器中。用前于130℃烘5h。

氟化钠溶液:饱和水溶液。

3.2.7速灭磷标准品:纯度≥95%。3.2.8速灭磷标准溶液:准确称取适量的速灭磷标准品,用二氟甲烷溶解并配成浓度为1.00mg/mL的标准储备液,根据需要再用二氟甲烷稀释成适当浓度的标准工作溶液。3.3仅器和设备

3.3.1气相色谱仪,配有火焰光度检测器及磷滤光片(526nm)。3.3.2旋转蒸发器。

均质机:3000r/min。

心形瓶:200mL,带有定容5mL的尾管。抽滤漏斗:60mm(内径)

分液漏斗:500mL。

3.3.7抽滤瓶:250mL。

3.3.8微量注射器:10μL。

3.4测定步骤

3.4.1提取

称取试样40g(精确到0.1g)于均质瓶中,加入100mL丙酮,于3000r/min均质3min。提取液经用抽滤漏斗抽滤至抽滤瓶中,用50mL丙酮分3次洗涤均质瓶及滤渣,滤液并入抽滤瓶中。将滤液全部转移到500mL分液漏斗中,加入250mL水、25mL氯化钠饱和溶液,摇匀。加入50mL二氯甲烷,充分振荡2min,静置分层后,放出二氯甲烷层于烧杯中。水层中再加入50mL二氟甲烷,振荡提取。合并两次二氯甲烷提取液于烧杯中。

3.4.2净化

在二氯甲烷提取液中加入30g无水硫酸钠(3.2.3),不时用玻璃棒搅拌,放置30min使脱水。再加入1g氧化铝(3.2.5)、0.5g活性炭(3.2.4).用玻璃棒搅拌1min。用快速定量滤纸过滤于心形瓶中,残渣用少量二氯甲烷充分洗涤并过滤。合并滤液和洗液,于40℃以下水浴中减压浓缩(切勿使干),用二氟甲烧定容至5mL,溶液供气相色谱测定。3.4.3测定

3.4.3.1色谱条件

a)色谱柱:玻璃柱,1.6m×3.2mm(id).填充物为1.5%(m/m)0V-17+1.95%(m/m)QF-1涂于ChromosorbWAW-Carbowax2oM键合担体(100~200目);b)色谱柱温度:185℃;

c)进样器温度:220℃C;

d)检测器温度:260C;

e)氮气:纯度≥99.99%,65mL/minf)氢气:50mL/min;

g)空气:60mL/min;

h)进样量:2μL,

3.4.3.2色谱测定

根据样液中速灭磷含量情况,选定峰高相近的标准工作溶液。标准工作溶液和样液中速灭磷响应值均应在仪器检测线性范围内。对标准工作溶液和样液等体积参插进样测定。在上述色谱条件下,速灭碳2

SN0599-1996

色谱峰保留时间约为4min。标准品色谱图见附录A中图A1。3.4.4空白试验

除不加试样外,均按上述测定步骤进行。3.4.5结果计算和表述

用色谱数据处理机或按式(1)计算:h.c.y

式中:X—试样中速灭磷残留含量,mg/kg;h-样液中速灭磷的峰高,mm;

h,一-标准工作溶液中速灭磷的峰高,mm;一标准工作溶液中速灭磷的浓度,g/mL;V—样液最终定容体积,mL;

m-最终样液所代表的试样量.g。注:计算结果需扣除空白值。

4·测定低限、回收率

测定低限

本方法的测定低限为0.05mg/kg。4.2回收率

回收率的实验数据:

速灭磷添加浓度在0.05mg/kg时,回收率为89.4%;速灭磷添加浓度在0.1mg/kg时,回收率为88.1%;速灭磷添加浓度在0.5mg/kg时,回收率为91.5%。(1)

SN0599-1996

附录A

(提示的附录)

标准品气相色谱图

速灭磷标准品气相色谱图

SN05991996

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1-1993 \Directivesfor the work of standardization--Unit l:Drafting and presentation of standards-Part 1:General rulesfor drafting standards” and SN/T 0001-1995\General rules for drafting the standard methods for thedetermination of pesticide,veterinary drug residues and biotoxins in commodities for export.\ Themethods of determination of this standard was drafted by referring to relevant domestic and foreign lit-eratures through research,modification and verification. In addition,methods of sampling and samplepreparation are also specified in this standard.The limit of determination in this standard is defined on the basis of the current internationalmaximum limit for mevinphos residues in fruits and the sensitivity of the method.Annex Aof this standard is an informative annex.This standard was proposed by and is under the charge of the State Administration of Import andExport commodity Inspection of the People's Republic of China.This standard was drafted by the Liaoning Import and Export Commodity Inspection Bureau ofthe People's Republic of China and Shenyang Agriculture University.The main drafters of this standard are Gong Yingzi,Nu Shen,Zhou Yanming,Song Wenbin.This standard is a professional standard promulgated for thefirst time.Note: This English version,a translation from the Chinese text,is solely for guidance.Professional Standard of the People's Republic of ChinaforImportandExportCommodityInspectionSN0599-1996

Method for the determination ofmevinphosresiduesinfruitsforexport1Scope

This standard specifies the methods of samplingsample preparation and determination of mevinphos residues by gas chromatoqraphy in fruits for export.This standard is applicable to the determination of mevinphos residues in applefor exportSampling and sample preparation2

2.1Inspectionlot

Thequantityof aninspectionlotshouldnotbemorethan15oopackages.The characteristics of the cargo within the same inpection lot,such as packing,mark,origin,gradeand specification.should be the same.2.2Quantityof sampletaken

Numberofpackagesin

each inspection lot

26-100

101-250

251-1500

2.3 Sampling Procedure

Minimum number of

packages to be taken

A number of packages specified in 2.2 are taken at random and opened one by one.The sampleweight taken as the primary sample from each package should be at least 500 grams. The total weightof all primary samples should not be less than 2kg,which shall be sealed,labeled and sent to laboratoryin time.

2.4Preparationoftestsample

The combined primary sample is reduced to 1 kg,the edible portions are blended in a blender,andthen divided into two equal portions. Each portion is placed in a clean container as the test sample,which is sealed and labeled.2.5 Storageoftest sample

Thetestsamplesshouldbestoredbelow-18C.NoteIn the courseofsampling and samplepreparationprecautionmustbetaken to avoidthe contaminationoranyfactors which msy cause the change of residue content.ApprovedbytheStateAdministration ofImport and ExportCommodityInspection ofthePeople'sRepublicofChinaonNov.15,19966

ImplementedfromMay1.1997

3Mthodof determination

3.1Principle

SN0599-1996

The mevinphos residues in test sample are extracted with acetone, The extract is partitioned witha mixture of dichloromethane and water and the dichloromethane solution is cleand up with aluminaand charcoal.Then the solution is concentrated to a definite volume and analyzed by GC with flamephotometric detector,using external standard method.3.2Reagents and materials

Unless otherwise specified,all reagents should be analytically pure,\water\ is redistilled water.3.2.1Acetone.

3.2.2 Dichloromethane.

3.2.3Anhydrous sodium sulfate:Ignite at 650C for 4h,and keep in a desiccator.3.2.4Activated charcoal;For chromatographic use,2040mesh.Ignite at 600C for4hand store ina desiccator.Heat at 105 C for 4 h before use.3.2.5Alumina:Neutral,for chromatographic use,100-200mesh.Ignite at 550C for 4 h and storein a desiccator.Heat at 130C for 5 h before use.3.2.6Sodiumchloride solutionsaturated aqueous solution.3.2.7MevinphosstandardPurity≥95%.3.2.8 Mevinphos standard sodution:Accurately weigh a suitable amount of mevinphos standard,dis.solve in dichloromethane and prepare a solution of 1.O0 mg/mL in concentration as the standard stocksolution.Accordingto the requirement,dilute withdichloromethane to prepare a standardworking solution ofappropriateconcentration.3.3Apparatusand equipment

3.3.1Chromatograph;Equipped with flame photometric detector and phosphorous filter (526 nm).3.3.2 Rotary evaporator.

3.3.3Homogenizer3000or/min.

3.3.4Heart-shaped bottle;200mL,with5mLgraduated tip.3.3.5此内容来自标准下载网

Suctionfiliterfunnel:60mm(id).3.3.6

Separatoryfunnel:500mL.

Suctionflask:250mL

3.3.8Micro-syringe:10 μL.

3.4Procedure

3.4.1Extraction

Weigh ca 40 g of the test sample(accurate to 0.1 g) into a homogenizing bottle.Add 100 mL ofacetone and homogenize for 3min at 3 O00 r/min.Filter by suction the extract with a suction filter fun-nel into a suction flask,rinse the homogenizing bottle and the residue for several times with 50 mL ofacetone in total and filter.Combine the filtrates and the rinsings. Tranfer the filtrate into a 500-mLseparatory funnel,add 250 mL of water and 25 mL of saturated sodium chloride soiution and shake.Add 50 mL of dichloromethane and shake vigorously for 2 min. Let stand for separation. Drain thedichloromethane layer into a beaker.Re-extract the aqueous phase with 50 mL of dichloromethane asabove.Combinethedichloromethaneextracts in thebeaker.3.4.2Cleanup

Add 30 g of anhydrous sodium sulfate (3. 2. 3) into the dichloromethane extract. Let stand for 307

SN0599-1996

min with occasionally stirring with a glass rod to remove the water.Add 1 g of alumina (3. 2.5) and0.5 g of activated charcoal (3.2.4),and stir for 1 min.Filter the dichloromethane layer through high-speed quantitative filter paper into a heart shaped bottle,and wash the residue for several times withsamll amount of dichloromethane and filter. Combine the washings with the filtrates. The solution isconcentrated (never to dryness) in a 4o C water-bath under reduced pressure,and exactly diluted to 5mL with dichioromethane. The solution is used for chromatographic determination.3.4.3Determination

3.4.3.1 GC operating conditiona)Column:Glass1.6mX3.2mm(id).packedwith1.5%(m/m)0V-17+1.95%(m/m)QF-1onChromosorbWAW-Carbowax20Mcrosslinkedphase(100-200mesh);b)Column temperature:185C;

c)Injectionporttemperature:220Cd)Detector temperature:260'C;e)Nitrogen:Purity≥99.99%,65mL/min;f)Hydrogen:50mL/min;

g)Air60mL/min

3.4.3.2GC determination

According ro the approximate concentration of mevinphos in the sample solution,select the stan-dard working solution with similar peak height to that of sample solution, The responses of mevinphosin the standard solution and sample solution should be in the linear range of the instrumental detec-tion. The standard working solution should be injected in-between the injections of sample solution ofequal volume.Under the above chromatographic condition.the retention time of mevinphos is about 4min.For chromatogram of the standard,see fig.Al in annex A.3.4.4Blank test

The operation of the blank test is the same as that described in the method of determination butwithout addition of sample.

3.4.5Calculation and expression of result.The calculation of result is carried out by GC data processor or according to formula (1):h.c·V

X--the residue contentofmevinphos in test samplemg/kg;hthepeakheightofmevinphos inthesamplesolution.mm;h,the peak height of mevinphos in the standard working solution,mm;C-the concentration of mevinphos in the standard working solution,μg/mL;V-the final volume of sample solution,mL;mthe corresponding mass of test sample in the final sample solutiongNote: The blank value should be subttacted from the above result of calculstion.4Limit of determination and recovery4.1Limit ofdetermination

The limit of determination of this method is 0. 05 mg/kg.4.2Recovery

SN0599-1996

According to the experimental data,the fortifying concentrations of mevinphos and their correspondingrecoveriesare:

0.05mg/kg,therecovery89.4%;

0.1mg/kg,the recovery88.1%

0.5mg/kg,the recovery91.5%.

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。