SN 0600-1996

基本信息

标准号: SN 0600-1996

中文名称:出口粮谷中氟乐灵残留量检验方法

标准类别:商检行业标准(SN)

标准状态:现行

出版语种:简体中文

下载格式:.zip .pdf

下载大小:3943883

标准分类号

关联标准

出版信息

相关单位信息

标准简介

SN 0600-1996.Method for the determination of trifluralin residues in cereals for export.

1范围

SN 0600规定了出口粮谷中氟乐灵残留量检验的抽样、制样和气相色谱测定方法。

SN 0600适用于出口玉米中氟乐灵残留量的检验。

2曲样和制祥

2.1检验批

散积以不超过200t为一检验批,袋装以约2200袋为一检验批。

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。

2.2抽样数量

2.2.2散积货品

货堆高度不超过2m.按货堆面积分区设点,以50m2为一个职样区,每区设中心及四角距边缘1m处)5个点,每增加一个职样区,增加3个点。

2.3抽样工具

2.3.1金属双套管取样器:全长分1m、2m 均包括手柄)两种。内、外管同部位分段开几个槽口,每个槽口长15~20cm,口宽2. 0~2.5cm.内管的内径为2.5~3. 0cm ,职样器的探头长约7 cm.

2.3.2职样铲。

2.3.3分样板。

2.3.4盛样器:筒或袋,可密封。.

2.3. 5分样布或适用铺垫物。

2. 4抽样方法

2. 4. 1袋装抽样

2. 4. 1.1倒包抽样:从堆垛的各部位随机抽职2.2. 1规定的应抽样袋数的10% (每批-般不少于3袋) ,将袋口缝线全部拆开,平置于分样布或其他洁净的铺垫物上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m ,使袋内货物全部倒出。查看袋内和袋间品质是否均匀,确认情况正常后,用职样铲随机在各部位抽职样品,并立即将样品倒入盛样器内。每袋抽职样品的量应基本一致。

2.4. 1.2袋内抽样:按2. 2.1规定的应抽样袋数(扣除倒包抽样袋数) ,在垛堆四周上、中、下各层以曲线形走向随机抽取。用1m长的金属双套管职样器(2.3.1),关闭槽口,从每袋一角依斜对角方向插入袋内,然后旋转内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。每袋所抽取样品的量应与2.4. 1.1基本一致。

1范围

SN 0600规定了出口粮谷中氟乐灵残留量检验的抽样、制样和气相色谱测定方法。

SN 0600适用于出口玉米中氟乐灵残留量的检验。

2曲样和制祥

2.1检验批

散积以不超过200t为一检验批,袋装以约2200袋为一检验批。

同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。

2.2抽样数量

2.2.2散积货品

货堆高度不超过2m.按货堆面积分区设点,以50m2为一个职样区,每区设中心及四角距边缘1m处)5个点,每增加一个职样区,增加3个点。

2.3抽样工具

2.3.1金属双套管取样器:全长分1m、2m 均包括手柄)两种。内、外管同部位分段开几个槽口,每个槽口长15~20cm,口宽2. 0~2.5cm.内管的内径为2.5~3. 0cm ,职样器的探头长约7 cm.

2.3.2职样铲。

2.3.3分样板。

2.3.4盛样器:筒或袋,可密封。.

2.3. 5分样布或适用铺垫物。

2. 4抽样方法

2. 4. 1袋装抽样

2. 4. 1.1倒包抽样:从堆垛的各部位随机抽职2.2. 1规定的应抽样袋数的10% (每批-般不少于3袋) ,将袋口缝线全部拆开,平置于分样布或其他洁净的铺垫物上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m ,使袋内货物全部倒出。查看袋内和袋间品质是否均匀,确认情况正常后,用职样铲随机在各部位抽职样品,并立即将样品倒入盛样器内。每袋抽职样品的量应基本一致。

2.4. 1.2袋内抽样:按2. 2.1规定的应抽样袋数(扣除倒包抽样袋数) ,在垛堆四周上、中、下各层以曲线形走向随机抽取。用1m长的金属双套管职样器(2.3.1),关闭槽口,从每袋一角依斜对角方向插入袋内,然后旋转内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。每袋所抽取样品的量应与2.4. 1.1基本一致。

标准图片预览

标准内容

中华人民共和国进出口商品检验行业标准SN0600-1996

出口粮谷中氟乐灵残留量检验方法Method for the determination of trifluralinresidues in cereals for export1996-11-15发布

中华人民共和国国家进出口商品检验局1997-05-01实施

SN0600-1996

本标准是根据GB/T1.11993《标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》的要求而进行编写的。其中测定方法采用了美国食品药物管理局的农药残留量分析手册中的方法。技术内容与原方法相同,经验证后,按规定格式要求作了编辑性修改。在标准中同时制定了抽样和制样方法。

测定低限是根据国际上对粮谷中氟乐灵残留量的最高限量和测定方法的灵敏度而制定的。本标准的附录A为提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准起草单位:中华人民共和国内蒙古进出口商品检验局。本标准主要起草人:张曦静、包杰、潘国卿。本标准系首次发布的行业标准。1范围

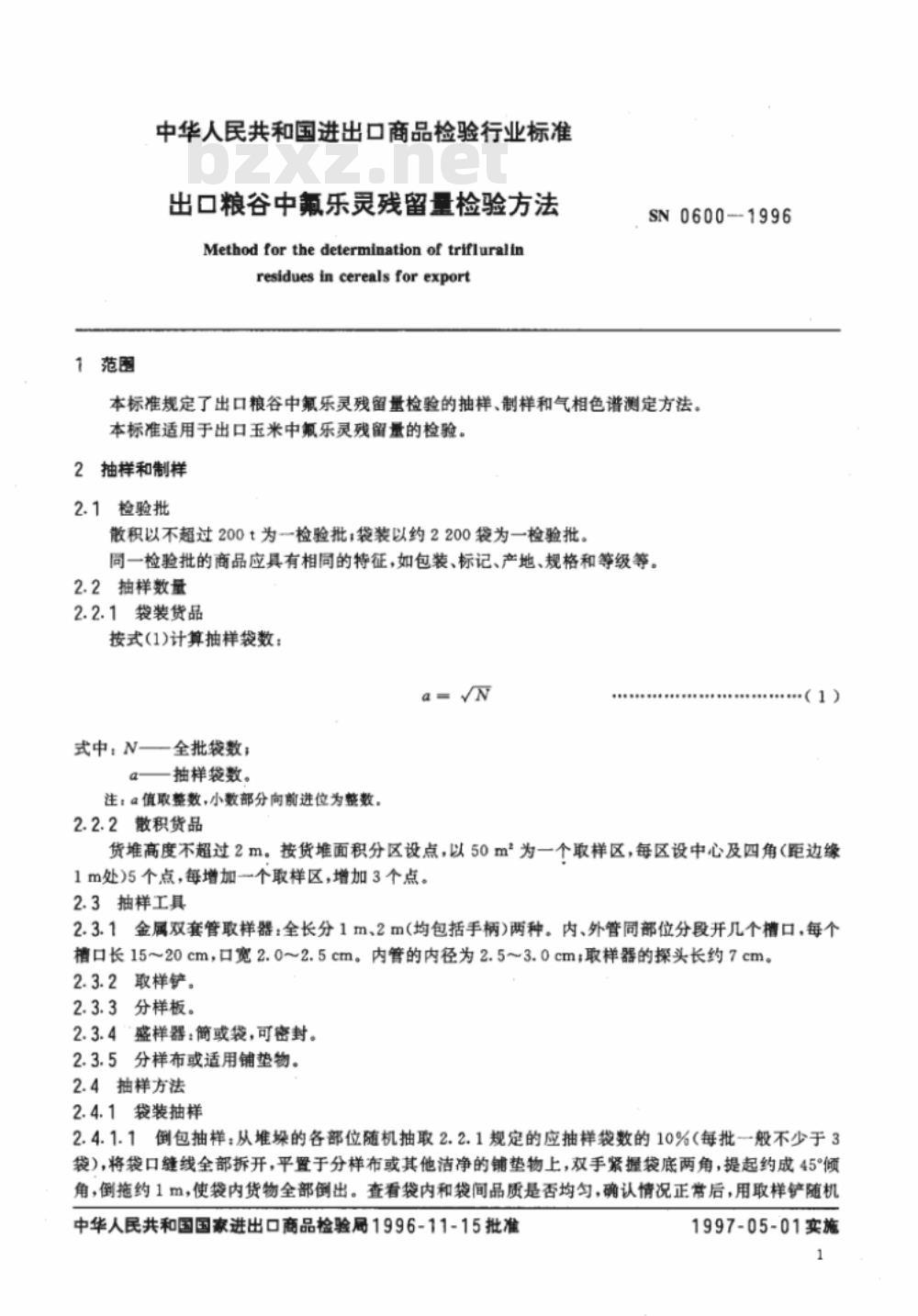

中华人民共和国进出口商品检验行业标准出口粮谷中氟乐灵残留量检验方法Methodforthedetermination of trifluralinresidues in cereals for exportSN0600--1996

本标准规定了出口粮谷中氟乐灵残留量检验的抽样、制样和气相色谱测定方法。本标准适用于出口玉米中氟乐灵残留量的检验。2抽样和制样

2.1检验批

散积以不超过200t为一检验批;袋装以约2200袋为一检验批。同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

2.2.1袋装货品

按式(1)计算抽样袋数:

式中:N——全批袋数;

Q—抽样袋数。

注:a值取整数,小数部分向前进位为整数,2.2.2散积货品

货堆高度不超过2m。按货堆面积分区设点,以50m为一个取样区,每区设中心及四角(距边缘1m处)5个点,每增加个取样区,增加3个点。2.3抽样工具

2.3.1金属双套管取样器:全长分1m、2m(均包括手柄)两种。内、外管同部位分段开几个槽口,每个槽口长15~20cm,口宽2.0~2.5cm。内管的内径为2.53.0cm;取样器的探头长约7cm。2.3.2取样铲。

2.3.3分样板。此内容来自标准下载网

2.3.4盛样器:筒或袋,可密封。2.3.5分样布或适用铺垫物。

2.4抽样方法

2.4.1袋装抽样

2.4.1.1倒包抽样:从堆垛的各部位随机抽取2.2.1规定的应抽样袋数的10%(每批一般不少于3袋),将袋口缝线全部拆开,平置于分样布或其他洁净的铺垫物上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m,使袋内货物全部倒出。查看袋内和袋间品质是否均匀,确认情况正常后,用取样铲随机中华人民共和国国家进出口商品检验局1996-11-15批准1997-05-01实施

SN0600-1996

在各部位抽取样品,并立即将样品倒入盛样器内。每袋抽取样品的量应基本一致。2.4.1.2袋内抽样:按2.2.1规定的应抽样袋数(扣除倒包抽样袋数),在垛堆四周上、中、下各层以曲线形走向随机抽取。用1m长的金属双套管取样器(2.3.1),关闭槽口,从每袋一角依斜对角方向插入袋内,然后旋转内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。每袋所抽取样品的量应与2.4.1.1基本致。每批所抽取的样品总量应不少4kg。2.4.2散积抽样

按2.2.2规定的取样点,逐点抽取样品。将取样器(2.3.1)槽口关闭,以斜倾45°角度插入粮堆至相应深度,旋转取样器内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。从各点所抽取的样品量应基本一致。每批所抽取的样品总量应不少于4kg。2.4.3大样缩分

袋装样品:合并从袋内和倒包抽样所取全部样品,例于分样布上,用分样板按四分法缩分样品至不少于2kg,盛于盛样器内,加封后标明标记,并及时送交实验室。散积样品:将抽取的全部样品,倒于分样布上,以下按上述袋装样品方法进行。2.5试样制备

将样品按四分法缩分至1kg,全部磨碎并通过20目筛。混匀,均分成两份作为试样,分装入洁净的盛样器内,密封,标明标记。

2.6试样保存

将试样于一5℃以下避光保存。

注:在抽样和制样的操作过程中,必须防止样品受到污染或发生残留物含量的变化。3测定方法

3.1方法提要

试样中残留的氮乐灵用甲醇提取,提取液经用二氯甲烷进行液液分配。二氟甲烷层经脱水、浓缩、蒸发至干。以正已烷溶解提取物,溶液过弗罗里硅土柱净化后,用电子俘获检测器-气相色谱法测定,外标法定量。

3.2试剂和材料

除另有规定外,试剂均为分析纯,水为蒸馏水。3.2.1甲醇:重蒸馏。

3.2.2二氯甲烷:重蒸馏。

3.2.3正己烷:重蒸馏。

3.2.4苯:重蒸馏。

3.2.5氯化钠溶液:5%水溶液。

3.2.6无水硫酸钠:650℃灼烧4h,冷却后贮于密封容器中备用。3.2.7弗罗里硅土:层析用,60~80目,650℃灼烧4h,贮于密闭容器中。使用前一天再在130℃下烘5h,冷却后,置于广口瓶中,加入1.5%的水脱活,平衡24h,密封存放备用。3.2.8氟乐灵标准品:纯度≥99%。3.2.9氟乐灵标准贮备液:准确称取氟乐灵标准品,用苯配成浓度为0.10mg/mL的标准储备液。根据需要再用苯稀释成适当浓度的标准工作溶液。3.3仪器和设备

3.3.1气相色谱仪:配有电子俘获检测器。3.3.2微量注射器:1μL,10μL,2

3.3.3旋转蒸发器。

3.3.4振荡机。

3.3.5全玻璃蒸馏装置。

SN0600-1996

3.3.6无水硫酸钠柱:50mL简形分液漏斗,内装5cm高的无水硫酸钠。3.3.7弗罗里硅土柱:具有活塞的20cm×2.2cm(内径)层析管,柱底填约0.5cm脱脂棉,干法装入高7.5cm弗罗里硅土(3.2.7),上填高2.5cm无水硫酸钠(3.2.6)。使用前用100mL正已烷预淋洗,并在柱中保持正已烷层。

3.3.8刻度试管:具磨口塞,10mL。3.4测定步骤

3.4.1提取

称取试样12.5g(精确至0.01g),置于250mL具塞锥形烧瓶中,加入100mL甲醇,振荡提取20min,过滤于500mL分液漏斗中。用15mL甲醇分三次洗涤残渣,合并提取液和洗液。加入250mL5%氧化钠溶液,混匀。分别用30,30,20mL二氯甲烷提取三次,合并提取液,使通过无水硫酸钠柱,收集于250mL心形瓶中。再用15mL二氯甲烷分三次洗涤无水硫酸钠柱,洗液并入提取液中。用旋转蒸发器在50℃水浴中蒸去二氯甲烷。注;二氯甲烷一蒸发完,立卿取下心形瓶,以防氟乐灵报失。3.4.2净化

加入5mL正己烷,轻轻转动心形瓶,以溶解提取物。使之通过弗罗里硅土柱(3.3.7),再用4×5mL正已烧冲洗心形瓶,转入柱中。用正已烷进行洗脱,前70mL弃去,后100mL保留。收集保留部分洗脱液于250mL心形瓶中,蒸发至干。准确加入2.0mL苯以溶解残渣,溶液转移至10mL具塞玻璃试管中,待色谱测定。

注;避免苯落液直接暴露在阳光下。3.4.3测定

3.4.3.1色谱条件

a)色谱柱:玻璃柱1.6m×3mm(id),填充物为5%(m/m)SE-30涂于Chromos0rbW(80~100目);

b)色谱柱温度:180℃;

c)进样口温度:230℃;

d)检测器温度:230℃;

e)载气:氮气,纯度≥99.99%,50mL/min;f)进样量:0.5μL。

3.4.3.2气相色谐测定

根据试样中被测农药含量情况,选定峰高相近的标准工作溶液。标准工作液和待测样液中农药的响应值均应在仪器检测的线性范围内。对标准工作液与样液应等体积参插进样测定。在上述色谐条件下,氟乐灵保留时间约为2.2min。标准品色谱图见附录A中图A1。3.4.4空白试验

除不称取试样外,均按上述测定步骤进行。3.5结果计算和表述

用色谱数据处理机或按式(2)计算试样中氟乐灵的残留含量:V.c.h

式中:X——试样中氟乐灵含量,mg/kg;h-—-样液中氟乐灵的峰高,mm;SN0600--1996

h,—标准工作液中氟乐灵的峰高,mmc标准工作液中氟乐灵的浓度,g/mL;V---样液最终定容体积,mL;

一最终样液所代表的试样量,g。m

注:计算结果需将空白值扣除。测定低限、回收率

4.1测定低限

本方法的测定低限为0.005mg/kg。4.2回收率

玉米中氟乐灵的添加浓度和回收率的实验数据:添加浓度在0.005mg/kg时,回收率为90.0%;添加浓度在0.010mg/kg时,回收率为92.0%添加浓度在0.050mg/kg时,回收率为94.0%。SN0600-1996

附录A

(提示的附录)

标准品色谱图

图A1氟乐灵标准品色谱图

SN0600-1996

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1--1993 \Directives forthe work of standardization-Unit 1:Drafting and presentation of standards-Part 1:General rules fordrafting standards \and SN/T 0001--1995“General rules for drafting the standard methods for the deter-mination of pesticide,veterinary drug residues and biotoxins in commodities for export\. In this standard,the testing method for trifluralin residues in“Pesticide Analytical Manual\FDA of U.S.A. is-adopted asthe method of determination,which is thus technically identical with that of the original;only minor editori-al modification required for the stipulated format was made after going through verification.In addition,methods of sampling and sample preparation are also specified in this standard.The limit of determination in this standard is defined on the bases of the current international maxi-mum limit for trifluralin residues in cereals and the sensitivity of the method.AnnexA of this standard isaninformativeannex.This standiard was proposed by and is under the charge of the State Administration of Import and Ex-port Commodity Inspection of the People's Republic of China.This standard was drafted by Inner Mongolia Import and Export Commodity Inspection Bureau of thePeople'sRepublic of China,

Themain drafters of this standard are Zhang Xijing,Bao Jie,Pan GuoqingThis standard isa professional standard promulgated for thefirst timeNote; This English version,a translation from the Chinese text,is solely for guidanceProfessionalStandardofthePeople'sRepublicofChinaforImportandExportCommodityInspectionMethodforthedeterminationoftrifluralinresiduesincerealsforexport

SN0600-1996

This standard specifies the methods of sampling,sample preparation and determination of trifluralinresidues by gas chromatography in cereals for export.This standard is applicable to the determination of trifluralin residue content in maize for export.2Samplingandsamplepreparation2.1Inspectionlot

For the cargo in bulk,each inspection lot should not exceed 200 t.For the cargo in bags,each inspec-tionlotisabout2200bags.

Thecharacteristics ofthecargowithin the same inspectionlot,such as packing,mark,origin,specifica-tion,grade etc. ,should be the same.2.2Quantityofsampletaken

2.2.1Cargoinbags

Calculatethenumberofbagstobetakenbyformula(1):a=VN

N-total number of bags in a lot;anumberof bagstobetaken.

Note: If value α is with decimal,round off the decimal part,which is added as unity to the integral part of a2.2.2Cargo inbulk

The height of the cereal pile should not exceed 2 m. Set up areas and spots for sampling on the pilesurface. 50 m' is considered as an area,in which 5 spots shall be fixed,one in the.centre and four at fourcorners(1 m from the margins) of the area. For an additional area,3 more sampling spots should befixed.2.3Samplingtools

2.3.1Metallic double casing sampler: Length 1 m and 2 m (both including handle),with some slots ondifferent sections at the same heights for both inner and outer casings;length of slots:15-20 cm;width ofthe slots 2.0—2.5 cm;inside diameter of the inner casing:2.5—3.0 cm;the probe length of the sampler:ca7cm.

2.3.2Sampling shovel.

ApprovedbytheStateAdministrationofImport and ExportCommodityInspection ofthePeople's Republic of China on Nov.15,1996ImplementedfromMay.1,1997

2.3.3Plateforquartering

SN0600-1996

2.3.4Sample container:Can orbag,which canbesealed.2.3.5Cloth (or other suitablematerial)sheet:For sample dividing(quartering).2.4Samplingprocedure

2.4.1Forcargoinbags

2.4.1.1 Sampling by emptying outDraw 10 percent of the number of bags specified in 2. 2.1 (not lessthan 3 bags) at any part of the pile at random.Unseam and open the bag,and lay it on a clean cloth sheet(or other clean sheet). Grasp tight two corners of the bag bottom and raise up to an angle of 45°,tug back-ward for ca 1 m until all content of the bag is emptied out.Check whether the quality of goods is uniformwithin and between the bags. After confirming the goods are in normal condition,scoop up the sample fromdifferent parts of the out-poured,content with a shovel at random,and promptly place in a sample contain-er,The quantity of sample drawn from each bag should bebasically the seme.2.4.1.2Samplingfrom insidethebags:Draw the samples from the number of bags specified in 2.2.1(bydeducting the number of bags drawn in 2. 4. 1.1) as follows:Along the sine wave of the pile,draw sampiesfrom the bags ofupper,middle and lower parts around the pile at random.Insert the metallic double casingsampler(2.3. 1,length 1 m)(the slots should be closed while inserting in)diagonally into each bag.Turnthe inner casing to open the slots so that the sample may fill up the inner tube. Again turn the inner casingto close the slots and draw out the sampler.Promptly pour the sample into a sample container.The quantityof the sample drawn from each bag should be basically the same as in 2. 4.1.1.The total weight of the sample of each lot should be not less than 4 kg.2.4.2Sampling from the cargo in bulk;Insert the double casing sampler (2. 3.1) successively into thepile at the spots specified in 2. 2. 2 to an appropriate depth at 45° (the slots shouid be closed while insertingin). Turn the ininer casing to open the slots so that the sample may fill up the inner tube, Again turn the inner casing to close the slots and draw out the sampler.Promptly pour the sample into a sample container.The quantity of the sample drawn from all the spots shall be basically the same.The total weight of the sample of each lot should benot less than 4kg2.4.3 Reduction of gross sampleFor cargo in bags;Pour all the samples (from both 2. 4. 1.1 and 2. 4. 1.2) on to a clean sheet. Reduceto not less than 2 kg by quartering with a plate. Place in a sample container,seal,label and send to the laboratory in time.

For cargo in bulk;Pour all the drawn samples onto a clean sheet and proceed as for cargo in bags de-scribed above.

2.5Preparationof test sampleReduce the sample to ca 1 kg by quartering+grind thoroughly and let pass through a 20-mesh sieve,Mix thoroughly and divide into two equal portions,place in clean sample containers as the test samples,sealand label.

2.6Storageoftestsample

The test samples should be stored below-5C and kept away from light.Note: In the course of sampling and sample preparation,precaution must be taken to avoid contamination or any factorsthatmay cause change of theresiduecontent,3Methodof determination

3.1 Principle

SN0600—1996

The trifluralin residues in sample is extracted with methanol,the extract is treated by methanol-dichloromethane partitioning,then the dichloromethane solution is dehydrated,concentrated and evaporatedto dryness. The residue is dissolved with n-hexane and cleaned up by passing through a florisil column. Thetrifluralin is determined by GC-ECD,using external standard method.3.2Reagentsandmaterials

Unless otherwise specified,all reagents should be of analytical grade,wateris distilled water.3.2.1MethanolRedistilled.

3.2.2DichloromethaneRedistilled.3.2.3n-HexaneRedistlled.

3.2.4Benzene:Redistilled.

3.2.5Sodiumchloridesolution;5%aqueoussolution.3. 2.6Anhydrous sodium sulfate:gnite at 650'C for 4 h and keep in a tightly closed container after cool-ing.

3.2.7Florisil:For chromatographic use,60—80 mesh.Ignite at 650C for 4 h,keep in a closed container.Before use,it is activated again at 130'C for 5 h,then deactivated after cooling by adding 1. 5% of dis-tilled water. Keep in a tightly closed container and let stand overnight.3.2.8Trifluralin standard.Purity≥99%.3.2.9Trifluralin standard solution;Accurately weigh an adequate amount of trifluralin standard,dissolvein benzene and prepare a solution of o.10 mg/mL in concentration as the standard stock solution.Accord-ing to the requirment,prepare a standard working solution of appropriate concentration by diluting thestock solution with benzene.3.3Apparatusandequipment

3.3.1 Gas chromatograph,equipped with electron capture detector.3.3.2Micro-syringe:1 μL,10 μL.3.3.3Rotaryvacuumevaporator.3.3.4Shaker.

3.3.5All-glass distilling system.3. 3. 6Anhydrous sodium sulfate columnA cylinder-shaped funnel of 50 mL in capacity,filled with 5 cmheight of anhydrous sodium sulfate.3.3.7Florisil column:20X2. 2 cm(id) glass column,with round stopper,packed with 0.5 cm height ofabsorbent cotton at the bottom of the column and packed with7.5 cmheight of florisil (3.2.7)then covered with 2. 5 cm height of anhydrous sodium sulfate (3. 2. 6). Wash the column with 100 mL of n-hexanebeforeuseandretaina layerof hexaneonthecolumn.3.3.8Graduatedtest-tube;10mL,withgroundstopper.3.4Procedure

3.4.1Extraction

Weigh ca 12.5g of thetest sample(accurate to 0. 01 g) into a 250mL conical flask withground stopper,add 100 mL of methanol,stopper and shake for 20 min by a shaker.Filter the extract into a 500 mLseparatory funnel.Rinse the residue on the filter for three times with methanol(15 mL in total),combinethe filtrates into the same separatory funnel,then add 250 mL of 5% sodium chloride solution,mixed. Thesolution is extracted successively with 30,30 and 20mLof dichloromethane.Letthe combined extract passthrough the column of anhydrous sodium sulfate,then rinse the column for three times with 15 mL ofdichloromethane in total. Collect the solution in a heart-shaped flask and evaporate off the dichloromethane9

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

出口粮谷中氟乐灵残留量检验方法Method for the determination of trifluralinresidues in cereals for export1996-11-15发布

中华人民共和国国家进出口商品检验局1997-05-01实施

SN0600-1996

本标准是根据GB/T1.11993《标准化工作导则第1单元:标准的起草与表述规则第1部分:标准编写的基本规定》及SN/T0001一1995《出口商品中农药、兽药残留量及生物毒素检验方法标准编写的基本规定》的要求而进行编写的。其中测定方法采用了美国食品药物管理局的农药残留量分析手册中的方法。技术内容与原方法相同,经验证后,按规定格式要求作了编辑性修改。在标准中同时制定了抽样和制样方法。

测定低限是根据国际上对粮谷中氟乐灵残留量的最高限量和测定方法的灵敏度而制定的。本标准的附录A为提示的附录。

本标准由中华人民共和国国家进出口商品检验局提出并归口。本标准起草单位:中华人民共和国内蒙古进出口商品检验局。本标准主要起草人:张曦静、包杰、潘国卿。本标准系首次发布的行业标准。1范围

中华人民共和国进出口商品检验行业标准出口粮谷中氟乐灵残留量检验方法Methodforthedetermination of trifluralinresidues in cereals for exportSN0600--1996

本标准规定了出口粮谷中氟乐灵残留量检验的抽样、制样和气相色谱测定方法。本标准适用于出口玉米中氟乐灵残留量的检验。2抽样和制样

2.1检验批

散积以不超过200t为一检验批;袋装以约2200袋为一检验批。同一检验批的商品应具有相同的特征,如包装、标记、产地、规格和等级等。2.2抽样数量

2.2.1袋装货品

按式(1)计算抽样袋数:

式中:N——全批袋数;

Q—抽样袋数。

注:a值取整数,小数部分向前进位为整数,2.2.2散积货品

货堆高度不超过2m。按货堆面积分区设点,以50m为一个取样区,每区设中心及四角(距边缘1m处)5个点,每增加个取样区,增加3个点。2.3抽样工具

2.3.1金属双套管取样器:全长分1m、2m(均包括手柄)两种。内、外管同部位分段开几个槽口,每个槽口长15~20cm,口宽2.0~2.5cm。内管的内径为2.53.0cm;取样器的探头长约7cm。2.3.2取样铲。

2.3.3分样板。此内容来自标准下载网

2.3.4盛样器:筒或袋,可密封。2.3.5分样布或适用铺垫物。

2.4抽样方法

2.4.1袋装抽样

2.4.1.1倒包抽样:从堆垛的各部位随机抽取2.2.1规定的应抽样袋数的10%(每批一般不少于3袋),将袋口缝线全部拆开,平置于分样布或其他洁净的铺垫物上,双手紧握袋底两角,提起约成45°倾角,倒拖约1m,使袋内货物全部倒出。查看袋内和袋间品质是否均匀,确认情况正常后,用取样铲随机中华人民共和国国家进出口商品检验局1996-11-15批准1997-05-01实施

SN0600-1996

在各部位抽取样品,并立即将样品倒入盛样器内。每袋抽取样品的量应基本一致。2.4.1.2袋内抽样:按2.2.1规定的应抽样袋数(扣除倒包抽样袋数),在垛堆四周上、中、下各层以曲线形走向随机抽取。用1m长的金属双套管取样器(2.3.1),关闭槽口,从每袋一角依斜对角方向插入袋内,然后旋转内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。每袋所抽取样品的量应与2.4.1.1基本致。每批所抽取的样品总量应不少4kg。2.4.2散积抽样

按2.2.2规定的取样点,逐点抽取样品。将取样器(2.3.1)槽口关闭,以斜倾45°角度插入粮堆至相应深度,旋转取样器内管以开启槽口,待样品流满内管后,再旋转内管以关闭槽口。抽出取样器,立即将样品倒入盛样器内。从各点所抽取的样品量应基本一致。每批所抽取的样品总量应不少于4kg。2.4.3大样缩分

袋装样品:合并从袋内和倒包抽样所取全部样品,例于分样布上,用分样板按四分法缩分样品至不少于2kg,盛于盛样器内,加封后标明标记,并及时送交实验室。散积样品:将抽取的全部样品,倒于分样布上,以下按上述袋装样品方法进行。2.5试样制备

将样品按四分法缩分至1kg,全部磨碎并通过20目筛。混匀,均分成两份作为试样,分装入洁净的盛样器内,密封,标明标记。

2.6试样保存

将试样于一5℃以下避光保存。

注:在抽样和制样的操作过程中,必须防止样品受到污染或发生残留物含量的变化。3测定方法

3.1方法提要

试样中残留的氮乐灵用甲醇提取,提取液经用二氯甲烷进行液液分配。二氟甲烷层经脱水、浓缩、蒸发至干。以正已烷溶解提取物,溶液过弗罗里硅土柱净化后,用电子俘获检测器-气相色谱法测定,外标法定量。

3.2试剂和材料

除另有规定外,试剂均为分析纯,水为蒸馏水。3.2.1甲醇:重蒸馏。

3.2.2二氯甲烷:重蒸馏。

3.2.3正己烷:重蒸馏。

3.2.4苯:重蒸馏。

3.2.5氯化钠溶液:5%水溶液。

3.2.6无水硫酸钠:650℃灼烧4h,冷却后贮于密封容器中备用。3.2.7弗罗里硅土:层析用,60~80目,650℃灼烧4h,贮于密闭容器中。使用前一天再在130℃下烘5h,冷却后,置于广口瓶中,加入1.5%的水脱活,平衡24h,密封存放备用。3.2.8氟乐灵标准品:纯度≥99%。3.2.9氟乐灵标准贮备液:准确称取氟乐灵标准品,用苯配成浓度为0.10mg/mL的标准储备液。根据需要再用苯稀释成适当浓度的标准工作溶液。3.3仪器和设备

3.3.1气相色谱仪:配有电子俘获检测器。3.3.2微量注射器:1μL,10μL,2

3.3.3旋转蒸发器。

3.3.4振荡机。

3.3.5全玻璃蒸馏装置。

SN0600-1996

3.3.6无水硫酸钠柱:50mL简形分液漏斗,内装5cm高的无水硫酸钠。3.3.7弗罗里硅土柱:具有活塞的20cm×2.2cm(内径)层析管,柱底填约0.5cm脱脂棉,干法装入高7.5cm弗罗里硅土(3.2.7),上填高2.5cm无水硫酸钠(3.2.6)。使用前用100mL正已烷预淋洗,并在柱中保持正已烷层。

3.3.8刻度试管:具磨口塞,10mL。3.4测定步骤

3.4.1提取

称取试样12.5g(精确至0.01g),置于250mL具塞锥形烧瓶中,加入100mL甲醇,振荡提取20min,过滤于500mL分液漏斗中。用15mL甲醇分三次洗涤残渣,合并提取液和洗液。加入250mL5%氧化钠溶液,混匀。分别用30,30,20mL二氯甲烷提取三次,合并提取液,使通过无水硫酸钠柱,收集于250mL心形瓶中。再用15mL二氯甲烷分三次洗涤无水硫酸钠柱,洗液并入提取液中。用旋转蒸发器在50℃水浴中蒸去二氯甲烷。注;二氯甲烷一蒸发完,立卿取下心形瓶,以防氟乐灵报失。3.4.2净化

加入5mL正己烷,轻轻转动心形瓶,以溶解提取物。使之通过弗罗里硅土柱(3.3.7),再用4×5mL正已烧冲洗心形瓶,转入柱中。用正已烷进行洗脱,前70mL弃去,后100mL保留。收集保留部分洗脱液于250mL心形瓶中,蒸发至干。准确加入2.0mL苯以溶解残渣,溶液转移至10mL具塞玻璃试管中,待色谱测定。

注;避免苯落液直接暴露在阳光下。3.4.3测定

3.4.3.1色谱条件

a)色谱柱:玻璃柱1.6m×3mm(id),填充物为5%(m/m)SE-30涂于Chromos0rbW(80~100目);

b)色谱柱温度:180℃;

c)进样口温度:230℃;

d)检测器温度:230℃;

e)载气:氮气,纯度≥99.99%,50mL/min;f)进样量:0.5μL。

3.4.3.2气相色谐测定

根据试样中被测农药含量情况,选定峰高相近的标准工作溶液。标准工作液和待测样液中农药的响应值均应在仪器检测的线性范围内。对标准工作液与样液应等体积参插进样测定。在上述色谐条件下,氟乐灵保留时间约为2.2min。标准品色谱图见附录A中图A1。3.4.4空白试验

除不称取试样外,均按上述测定步骤进行。3.5结果计算和表述

用色谱数据处理机或按式(2)计算试样中氟乐灵的残留含量:V.c.h

式中:X——试样中氟乐灵含量,mg/kg;h-—-样液中氟乐灵的峰高,mm;SN0600--1996

h,—标准工作液中氟乐灵的峰高,mmc标准工作液中氟乐灵的浓度,g/mL;V---样液最终定容体积,mL;

一最终样液所代表的试样量,g。m

注:计算结果需将空白值扣除。测定低限、回收率

4.1测定低限

本方法的测定低限为0.005mg/kg。4.2回收率

玉米中氟乐灵的添加浓度和回收率的实验数据:添加浓度在0.005mg/kg时,回收率为90.0%;添加浓度在0.010mg/kg时,回收率为92.0%添加浓度在0.050mg/kg时,回收率为94.0%。SN0600-1996

附录A

(提示的附录)

标准品色谱图

图A1氟乐灵标准品色谱图

SN0600-1996

Foreword

This standard was drafted in accordance with the requirements of GB/T 1.1--1993 \Directives forthe work of standardization-Unit 1:Drafting and presentation of standards-Part 1:General rules fordrafting standards \and SN/T 0001--1995“General rules for drafting the standard methods for the deter-mination of pesticide,veterinary drug residues and biotoxins in commodities for export\. In this standard,the testing method for trifluralin residues in“Pesticide Analytical Manual\FDA of U.S.A. is-adopted asthe method of determination,which is thus technically identical with that of the original;only minor editori-al modification required for the stipulated format was made after going through verification.In addition,methods of sampling and sample preparation are also specified in this standard.The limit of determination in this standard is defined on the bases of the current international maxi-mum limit for trifluralin residues in cereals and the sensitivity of the method.AnnexA of this standard isaninformativeannex.This standiard was proposed by and is under the charge of the State Administration of Import and Ex-port Commodity Inspection of the People's Republic of China.This standard was drafted by Inner Mongolia Import and Export Commodity Inspection Bureau of thePeople'sRepublic of China,

Themain drafters of this standard are Zhang Xijing,Bao Jie,Pan GuoqingThis standard isa professional standard promulgated for thefirst timeNote; This English version,a translation from the Chinese text,is solely for guidanceProfessionalStandardofthePeople'sRepublicofChinaforImportandExportCommodityInspectionMethodforthedeterminationoftrifluralinresiduesincerealsforexport

SN0600-1996

This standard specifies the methods of sampling,sample preparation and determination of trifluralinresidues by gas chromatography in cereals for export.This standard is applicable to the determination of trifluralin residue content in maize for export.2Samplingandsamplepreparation2.1Inspectionlot

For the cargo in bulk,each inspection lot should not exceed 200 t.For the cargo in bags,each inspec-tionlotisabout2200bags.

Thecharacteristics ofthecargowithin the same inspectionlot,such as packing,mark,origin,specifica-tion,grade etc. ,should be the same.2.2Quantityofsampletaken

2.2.1Cargoinbags

Calculatethenumberofbagstobetakenbyformula(1):a=VN

N-total number of bags in a lot;anumberof bagstobetaken.

Note: If value α is with decimal,round off the decimal part,which is added as unity to the integral part of a2.2.2Cargo inbulk

The height of the cereal pile should not exceed 2 m. Set up areas and spots for sampling on the pilesurface. 50 m' is considered as an area,in which 5 spots shall be fixed,one in the.centre and four at fourcorners(1 m from the margins) of the area. For an additional area,3 more sampling spots should befixed.2.3Samplingtools

2.3.1Metallic double casing sampler: Length 1 m and 2 m (both including handle),with some slots ondifferent sections at the same heights for both inner and outer casings;length of slots:15-20 cm;width ofthe slots 2.0—2.5 cm;inside diameter of the inner casing:2.5—3.0 cm;the probe length of the sampler:ca7cm.

2.3.2Sampling shovel.

ApprovedbytheStateAdministrationofImport and ExportCommodityInspection ofthePeople's Republic of China on Nov.15,1996ImplementedfromMay.1,1997

2.3.3Plateforquartering

SN0600-1996

2.3.4Sample container:Can orbag,which canbesealed.2.3.5Cloth (or other suitablematerial)sheet:For sample dividing(quartering).2.4Samplingprocedure

2.4.1Forcargoinbags

2.4.1.1 Sampling by emptying outDraw 10 percent of the number of bags specified in 2. 2.1 (not lessthan 3 bags) at any part of the pile at random.Unseam and open the bag,and lay it on a clean cloth sheet(or other clean sheet). Grasp tight two corners of the bag bottom and raise up to an angle of 45°,tug back-ward for ca 1 m until all content of the bag is emptied out.Check whether the quality of goods is uniformwithin and between the bags. After confirming the goods are in normal condition,scoop up the sample fromdifferent parts of the out-poured,content with a shovel at random,and promptly place in a sample contain-er,The quantity of sample drawn from each bag should bebasically the seme.2.4.1.2Samplingfrom insidethebags:Draw the samples from the number of bags specified in 2.2.1(bydeducting the number of bags drawn in 2. 4. 1.1) as follows:Along the sine wave of the pile,draw sampiesfrom the bags ofupper,middle and lower parts around the pile at random.Insert the metallic double casingsampler(2.3. 1,length 1 m)(the slots should be closed while inserting in)diagonally into each bag.Turnthe inner casing to open the slots so that the sample may fill up the inner tube. Again turn the inner casingto close the slots and draw out the sampler.Promptly pour the sample into a sample container.The quantityof the sample drawn from each bag should be basically the same as in 2. 4.1.1.The total weight of the sample of each lot should be not less than 4 kg.2.4.2Sampling from the cargo in bulk;Insert the double casing sampler (2. 3.1) successively into thepile at the spots specified in 2. 2. 2 to an appropriate depth at 45° (the slots shouid be closed while insertingin). Turn the ininer casing to open the slots so that the sample may fill up the inner tube, Again turn the inner casing to close the slots and draw out the sampler.Promptly pour the sample into a sample container.The quantity of the sample drawn from all the spots shall be basically the same.The total weight of the sample of each lot should benot less than 4kg2.4.3 Reduction of gross sampleFor cargo in bags;Pour all the samples (from both 2. 4. 1.1 and 2. 4. 1.2) on to a clean sheet. Reduceto not less than 2 kg by quartering with a plate. Place in a sample container,seal,label and send to the laboratory in time.

For cargo in bulk;Pour all the drawn samples onto a clean sheet and proceed as for cargo in bags de-scribed above.

2.5Preparationof test sampleReduce the sample to ca 1 kg by quartering+grind thoroughly and let pass through a 20-mesh sieve,Mix thoroughly and divide into two equal portions,place in clean sample containers as the test samples,sealand label.

2.6Storageoftestsample

The test samples should be stored below-5C and kept away from light.Note: In the course of sampling and sample preparation,precaution must be taken to avoid contamination or any factorsthatmay cause change of theresiduecontent,3Methodof determination

3.1 Principle

SN0600—1996

The trifluralin residues in sample is extracted with methanol,the extract is treated by methanol-dichloromethane partitioning,then the dichloromethane solution is dehydrated,concentrated and evaporatedto dryness. The residue is dissolved with n-hexane and cleaned up by passing through a florisil column. Thetrifluralin is determined by GC-ECD,using external standard method.3.2Reagentsandmaterials

Unless otherwise specified,all reagents should be of analytical grade,wateris distilled water.3.2.1MethanolRedistilled.

3.2.2DichloromethaneRedistilled.3.2.3n-HexaneRedistlled.

3.2.4Benzene:Redistilled.

3.2.5Sodiumchloridesolution;5%aqueoussolution.3. 2.6Anhydrous sodium sulfate:gnite at 650'C for 4 h and keep in a tightly closed container after cool-ing.

3.2.7Florisil:For chromatographic use,60—80 mesh.Ignite at 650C for 4 h,keep in a closed container.Before use,it is activated again at 130'C for 5 h,then deactivated after cooling by adding 1. 5% of dis-tilled water. Keep in a tightly closed container and let stand overnight.3.2.8Trifluralin standard.Purity≥99%.3.2.9Trifluralin standard solution;Accurately weigh an adequate amount of trifluralin standard,dissolvein benzene and prepare a solution of o.10 mg/mL in concentration as the standard stock solution.Accord-ing to the requirment,prepare a standard working solution of appropriate concentration by diluting thestock solution with benzene.3.3Apparatusandequipment

3.3.1 Gas chromatograph,equipped with electron capture detector.3.3.2Micro-syringe:1 μL,10 μL.3.3.3Rotaryvacuumevaporator.3.3.4Shaker.

3.3.5All-glass distilling system.3. 3. 6Anhydrous sodium sulfate columnA cylinder-shaped funnel of 50 mL in capacity,filled with 5 cmheight of anhydrous sodium sulfate.3.3.7Florisil column:20X2. 2 cm(id) glass column,with round stopper,packed with 0.5 cm height ofabsorbent cotton at the bottom of the column and packed with7.5 cmheight of florisil (3.2.7)then covered with 2. 5 cm height of anhydrous sodium sulfate (3. 2. 6). Wash the column with 100 mL of n-hexanebeforeuseandretaina layerof hexaneonthecolumn.3.3.8Graduatedtest-tube;10mL,withgroundstopper.3.4Procedure

3.4.1Extraction

Weigh ca 12.5g of thetest sample(accurate to 0. 01 g) into a 250mL conical flask withground stopper,add 100 mL of methanol,stopper and shake for 20 min by a shaker.Filter the extract into a 500 mLseparatory funnel.Rinse the residue on the filter for three times with methanol(15 mL in total),combinethe filtrates into the same separatory funnel,then add 250 mL of 5% sodium chloride solution,mixed. Thesolution is extracted successively with 30,30 and 20mLof dichloromethane.Letthe combined extract passthrough the column of anhydrous sodium sulfate,then rinse the column for three times with 15 mL ofdichloromethane in total. Collect the solution in a heart-shaped flask and evaporate off the dichloromethane9

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。