SN/T 4063-2014

基本信息

标准号: SN/T 4063-2014

中文名称:出口植物性中药材中汞含量的测定直接进样-冷原子吸收光谱法

标准类别:商检行业标准(SN)

标准状态:现行

出版语种:简体中文

下载格式:.zip .pdf

下载大小:10336432

相关标签: 出口 植物性 中药材 含量 测定 直接 原子 吸收光谱

标准分类号

关联标准

出版信息

相关单位信息

标准简介

SN/T 4063-2014.Determination of mercury in botanic Chinese medicinal material for export-

Direct injection-cold atomic absorption spectroscopy method.

1范围

SN/T 4063规定了植物性中药材中汞含量的直接进样冷原子吸收光谱测定方法。

SN/T 4063适用于人参、甘草、大青叶、紫苏叶、菊花、红花.枸杞、山楂、麻黄、藿香、黄柏、肉桂等植物性中药材中汞含量的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T602化学试剂杂质测定用标准溶液的制备

GB/T5330工业用金属丝编织方孔筛网

GB/T6682分析实验室用水规格和试验方法:

3方法提要

样品通过进样器导人测汞仪中,经干燥后热分解,分解后的汞被还原成汞原子,汞原子蒸气在齐化管中进行金汞齐化反应、高温解析后在波长253.65nm处进行测定,按照标准曲线法定量。

4试剂和材料

除另有规定外,所用试剂均为优级纯,水为GB/T 6682规定的一级水。

4.1 硝酸:优级纯。

4.2 10% 硝酸溶液:量取100mL硝酸(4.1),用水稀释成1000mL。

4.3重铬酸钾。

4.4重铬酸钾溶液(1g/L):称取0.1g重铬酸钾(4.3)溶于100mL水中。

4.5汞标准储备溶液(1000mg/L):按GB/T602方法配制,或者直接使用有证标准物质。

4.6汞标准中间溶液(20 mg/L):准确移取2 mL汞标准溶液(4.5)于100mL的容量瓶中,加入1mL重铬酸钾溶液(4.4),用硝酸溶液(4.2)定容,混匀,于室温下存储。

Direct injection-cold atomic absorption spectroscopy method.

1范围

SN/T 4063规定了植物性中药材中汞含量的直接进样冷原子吸收光谱测定方法。

SN/T 4063适用于人参、甘草、大青叶、紫苏叶、菊花、红花.枸杞、山楂、麻黄、藿香、黄柏、肉桂等植物性中药材中汞含量的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T602化学试剂杂质测定用标准溶液的制备

GB/T5330工业用金属丝编织方孔筛网

GB/T6682分析实验室用水规格和试验方法:

3方法提要

样品通过进样器导人测汞仪中,经干燥后热分解,分解后的汞被还原成汞原子,汞原子蒸气在齐化管中进行金汞齐化反应、高温解析后在波长253.65nm处进行测定,按照标准曲线法定量。

4试剂和材料

除另有规定外,所用试剂均为优级纯,水为GB/T 6682规定的一级水。

4.1 硝酸:优级纯。

4.2 10% 硝酸溶液:量取100mL硝酸(4.1),用水稀释成1000mL。

4.3重铬酸钾。

4.4重铬酸钾溶液(1g/L):称取0.1g重铬酸钾(4.3)溶于100mL水中。

4.5汞标准储备溶液(1000mg/L):按GB/T602方法配制,或者直接使用有证标准物质。

4.6汞标准中间溶液(20 mg/L):准确移取2 mL汞标准溶液(4.5)于100mL的容量瓶中,加入1mL重铬酸钾溶液(4.4),用硝酸溶液(4.2)定容,混匀,于室温下存储。

标准图片预览

标准内容

中华人民共和国出入境检验检疫行业标准SN/T4063—2014

出口植物性中药材中汞含量的测定直接进样-冷原子吸收光谱法

Determination of mercury in botanic Chinese medicinal material for export-Directinjection-coldatomicabsorptionspectroscopymethod2014-11-19发布

中华人民共和国

国家质量监督检验检疫总局

2015-05-01实施

本标准按照GB/T1.1—2009给出的规则起草。SN/T4063-—2014

请注意本文件的某些内容可能涉及专利。本文件的发布机构不承担识别这些专利的责任本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国重庆出人境检验检疫局,本标准主要起草人:郑国灿、李贤良、朱美文、王晶、张雷、刘毅、陈江、向清华。1范围

出口植物性中药材中汞含量的测定直接进样-冷原子吸收光谱法

本标准规定了植物性中药材中汞含量的直接进样-冷原了吸收光谱测定方法。SN/T4063-—2014bzxZ.net

本标准适用于人参、廿草、大青叶、紫苏叶、菊花、红花、枸杞、山楂、麻黄、藿香、黄柏、肉桂等植物性中药材中汞含量的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。GB/T602化学试剂杂质测定用标准溶液的制备GB/T5330工业用金属丝编织方孔筛网GB/T6682分析实验室用水规格和试验方法3方法提要

样品通过进样器导人测汞仪中,经干燥后热分解,分解后的汞被还原成汞原子,汞原子蒸气在齐化管中进行金汞齐化反应、高温解析后在波长253.65nm处进行测定,按照标准曲线法定量。4试剂和材料

除另有规定外,所用试剂均为优级纯,水为GB/T6682规定的一级水。4.1硝酸:优级纯。

4.210%硝酸溶液:量取100mL硝酸(4.1)用水稀释成1000mL4.3重铬酸钾。

4.4重铬酸钾溶液(1g/L):称取0.1g重铬酸钾(4.3)溶于100mL水中。4.5汞标准储备溶液(1000mg/L):按GB/T602方法配制,或者直接使用有证标准物质。4.6汞标准中间溶液(20mg/L):准确移取2mL汞标准溶液(4.5)于100mL的容量瓶中,加入1ml重铬酸钾溶液(4.4),用硝酸溶液(4.2)定容,混,于室温下存储。4.7汞标准中间溶液(2.0mg/L):准确移取10mL求标准中间溶液(4.6)于100mL的容量瓶中,加入1mL重铬酸钾溶液(4.4),用水定容,混匀。此溶液含汞2.0μg/mL(溶液用时现配)。4.8汞标准工作溶液:分别移取0mL、0.10ml.0.25mL0.50mL、1.50mL、2.50mL、5.00mL、10.00ml15.00mL汞标准中间溶液(4.7)和2.5mL、5.0mL、15.0ml、25.0mL汞标准中间溶液(4.6)于两组100mL的容量瓶中,用水稀释至刻度,混勾。此时标准工作溶液对应的汞浓度分别为0μg/L、2μg/L、5μg/L、10ug/L、30μg/L、50μg/L、100μg/L、200μg/L、300ug/L(低含量系列)和500ug/L、1000μg/L、3000uμg/L5000ug/L(高含量系列)。1

SN/T4063—2014

载气:氧气,纯度≥99.99%。

仪器和设备

5.1测汞仪:配2个吸收池。

5.2样品舟:材质为镍或相当者。分析天平:感量0.1mg。

移液器:量程10μl~200μ。

6试样的制备与保存

6.1取有代衣性样约200g,用分析研磨机将样品粉摩成细粉(95%以上粉末能通过符合GB/T5330中R40/3系列孔径为0.25mm的标准试验筛),装人洁净容器,存储于干燥器中。6.2制样操作过程中应防止样品受到污染或发生残留物含量的变化。7测定步骤

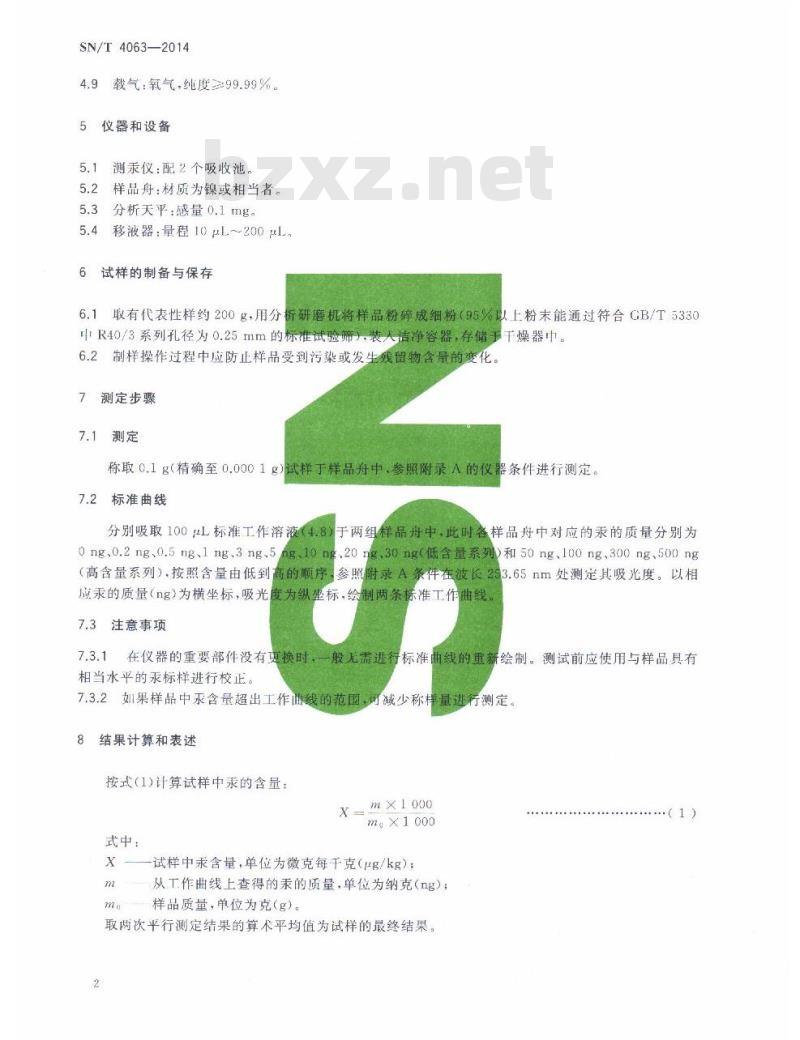

7.1测定

称取0.1g(精确至0.0001g)试样于样品舟中.参照附录A的仪器条件进行测定。7.2标准曲线

分别吸取100μL标准工作溶液(4.8)于两组样品舟中,此时各样品舟中对应的汞的质量分别为0ng、0.2ng、0.5ng、1ng、3ng、5ng、10ng、20ng、30ng(低含量系列)和50ng、100ng、300ng、500ng(高含量系列),按照含量由低到高的顺序,参照附录A条件在波长253.65nm处测定其吸光度。以相应汞的质量(ng)为横坐标,吸光度为纵坐标,绘制两条标准工作曲线。7.3注意事项

在仪器的重要部件没有更换时,一般无需进行标准曲线的重新绘制。测试前应使用与样品具有7.3.1

相当水平的汞标样进行校正。

7.3.2如果样品中汞含量超出工作曲线的范围,可减少称样量进行测定。8结果计算和表述

按式(1)计算试样中汞的含量:式中:

X=mx1000

maX1000

试样中汞含量,单位为微克每千克(ug/kg);从工作曲线上查得的汞的质量,单位为纳克(ng);样品质量,单位为克(g)。

取两次平行测定结果的算术平均值为试样的最终结果。2

.(1)

-TKAONKAca

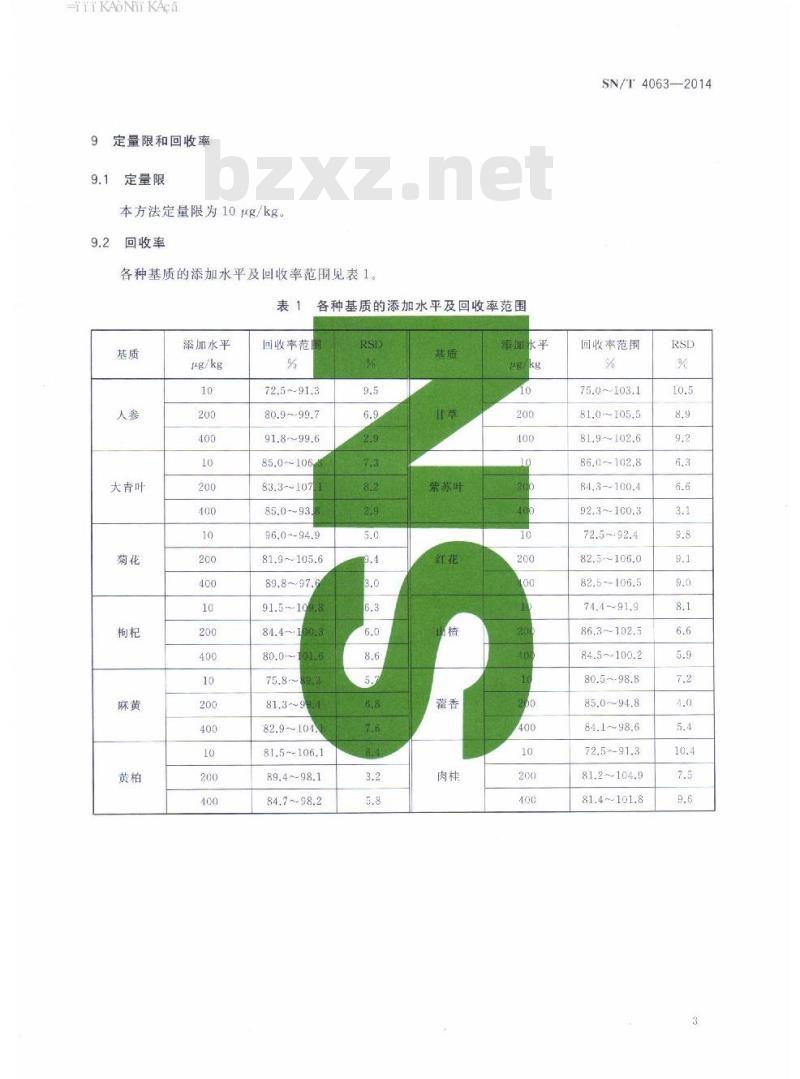

定量限和回收率

定量限

本方法定量限为10μg/kg。

回收率

各种基质的添加水平及回收率范围见表1。表1各种基质的添加水平及回收率范围基质

大青叶

添加水平

Iig/kg

回收率范围

72.5~-91.3

80.9~-99.7

91.8~99.6

96.0~-94.9

81.9~105.6

89.8~97.6

84.4~100.3

82.9-104.

81.5--106.1

89.4~-98.1

84.7--98.2

紫苏畔

SN/T4063—2014

回收率范围

75.0~103.1

81.0~105.5

81.9102.6

86.0--102.8

84.3~100.4

92.3~100.3

82.5~106.0

82.5-~106.5

74.4--91.9

86.3102.5

84.5~-100.2

80.5~98.8

85.0~94.8

81.2~104.9

81.4~-101.8

-TrKAONiKAca

SN/T4063—2014

附录A

(资料性附录)

仪器参考条件”

由于测试结果取决于所使用仪器,因此不可能给出测汞仪的通用参数。设定的参数应保证样品中的汞含量能够得到有效的测定。下列给出的参数证明是可行的:a)

干燥温度:300℃;

干燥时间:70S;

分解温度:800℃:

分解时间:120S;

催化温度:600℃;

等待时间:608

金汞齐温度:600℃;

汞齐化时间:125;

记录测量信号时问:1505;

载气输人压力:89.6kPa~-117.2kPa;载气输出压力2.6kPa~10.3kPa。1)非商业性声明:附录A所列参考条件是在TELEDYNELeemanLabsHydra-C型全白动测汞仪上完成的,此次列出试验用仪器型号仪为提供参考,并不涉及商业目的,鼓励标准使用者尝试不同厂家或型号的仪器,4

riKAoNiiKAca

Foreword

This standard was drafted according to GB/T 1.1-2009SN/T4063-—2014

Please note that some of the elements of this document may be involved in patent,issued the docu-ment does not assume the responsibility identification of these patents.This standard was proposed by and was under the charge of National Regulatory Commission for Cer-tificationandAccreditationofthePeople'sRepublicof China.The standard was drafted by Chongqing Entry-Exit Inspection and Quarantine Bureau of the People'sRepublicof China.

This standard was mainly drafted by Zheng Guocan,Li Xianliang,Zhu Meiwen,Wang JingZhang Lei.LiuYi,ChenJiang,XiangQinghuaNote:This English version,a translation from theChinesetextis solely forguidance.-rKAoNiKAca

SN/T4063—2014

DeterminationofmercuryinbotanicChinesemedicinal materialforexportDirect injection-coldatomic absorption spectroscopy method1Scope

The standard specifies the method of determination of mercury in botanic Chinese medicinal materialfor export by direct injection-colddatomicabsorption spectroscopyThis standard is applicable to the determination of mercury in ginseng,licorice,folium isatidis,perillaleaf,chrysanthemum,safflower,Chinesewolfberry.hawthorn.ephedra,patchouli,cortexphellodendri,cinna-mon.

2 Normative reference

Thefollowingdocumentsarenecessaryforthisstancshall applytothis standard.Forundated reference

ordatedreferences,onlydatededitionss.the latest edition of the normative document(in-cludingsubsequentamendments)isreferredtoapplies.GB/T602

GB/T5330

GB/T6682

Chenmical reagent

rd solutionsforimpurity

Preparations of standa

Industrialwovenmetal

re cloth(square opening

Waterforanalytical laboratory use3Principle

Specificationand

testmethod

The sample was guided into the the mercury analyzer through the injector,drying and thermal decomposition,mercury which decomposited was reduced to atomic mercury vapor,and was reacted ingold amalgam,and.quantitatied at the wavelengthof 253.65 nm after resolution underhigh tempera-ture,according to the standard curve4Reagents and materials

Unless specified,all reagents shall be of analytical grade;Water\is the first water prescribed byGB/T6682

-TKAONiKAca

4.1 Nitric acid: GR.

SN/T4063-—2014

4.2 Nitric acid solution(10%):dilute 100 mL nitric acid(4.1) to 1000 mL withwater.4.3Potassiumdichromate.

4.4Potassium dichromate solution (1g/L):Dilute0.1gPotassiumdichromate(4.3)to100mLwithwater.

4.5Mercury standard solution(1000mg/L):Prepared by GB/T602method,oruse certificated ref-erencematerial.

4.6Mercury standard middle solution(20 mg/LAccurately

measured2mLthestandard solution(4.5)in an100 mL volumetric flask andPotassium dichromate solution(4.4) andadded1ml

dissloved withnitric acid solution (4.toforma

standard solution was stored at the room tempeddle standardsolutionof 20 mg/L.Themiddle4.7Mercury standard middle solution(2.0 mg/L):Accuratelymeasured 10mL themiddle standardsolution(4.6))inan10omLvolumetricflaskandaddedm

umdichromatesolution(4.4)andotassu

dissloved withwatertoformamiddlestandard solution of2.Oμg/L4.8 Mercury standard working solution:Respectivelymeasured0mL.0.10mL0.25mL,0.50mL,mL.15.00mL

1.50mL.2.50mL,5.00mL,10.00

standardmiddlesolution(4.7)and2.5mL,mercury

in differentvolumetric flaskanddi-5.0mL,15.0mL,25.0mLmercurystandardmiddlesolution(4.6)luted to 100 mL with water.the conct50μg/L100μg/.200μg/L,300

5000μg/L(highcontentrange).4.9

Carriergas:Oxygen.purity≥99.995

Apparatus and equipment

2ugL.5μg/L,10μg/L,30μg/L,swereoug/L

rntrations

content

Mercury analyzer:With2absorption cell.range)

Sample boats:materials for nickel or equivalent.5.3E

Electronicbalance(0.1mg)

5.4Pipettes:the rangeof10μL~200μL.and500μg/L1000μg/L3000ug/

SN/T4063—2014

Sample preparation and storage6.1 Take a representative sample of about 200 g,crushed with grinding machine (which more than95%p0wder can through the0.25mm standardtest sieveofGB/T5330R40/3series).put intoaclean container,stored in a desiccator.6.2Certain measures shall be taken to prevent contamination of the samples or decomposition ofthe residues during the sample preparation procedure.7

Analytical procedure

Determination

Weigh 0.1 g (accurate to 0.000 1g) sample in the sample boat,and determined refer to instrumentconditionsinappendixA

Standard curve

Respectively absorb100μL standard working solution(4.8)in sampleboats,the contentsof mercurywere0ng.0.2ng.0.5ng,1ng.3ng.5ng.10ng.20ng,30ng(lowcontentrange)and50ng.100ng,300 ng.500 ng (high content range),then determined refer to instrument conditions in appendix Afrom low to high,drawing two standard working curve.Corresponding to the mercury mass (ng) asabscissa,absorbanceasordinate.7.3Note

7.3.1In general,the cuve don't need to draw,if the important component in the instrument withoutreplacement,themercury standard solution was used to calibrate before determination.Sampleweightcanbe reducedif mercurycontentbeyond thework curve7.3.2

Calculationand expression of result8

Calculatingthecontentof mercuryaccordingtotheformula(1)X=

where:

m×1000

m。×1000

thecontentofmercuryinthetestsample,ug/kg...1)

thecontentofmercurycheckedfromworkingcurve.ng;sampleweightg

Two parallel determinations on the average as the final results of the sampleLimitofquantification(LoQ)andrecovery9.1

TheLimitofquantificationwas10μg/kg。9.2

Recovery

The recoveries ranges of mercury in everymatrix were listed in table1.SN/T4063—2014

Tablel-The spiked levels andrecoveriesranges of mercuryineverymatrixMatrix

ginseng

folium

isatidis

chrysanthe

Chinese

wolfberry

ephedra

cortex

phellodendri

Spikedlevels

Recovery ranges

72.5~91.3

80.9~99.7

91.8~99.6

85.0~106.3

83.3~107.1

85.0~93.8

96.0~94.9

81.9~105.6

89.8~97.6

91.5~109.8

84.4~100.3

80.0~101.6

75.8~89.3

81.3~99.4

82.9~104.1

81.5~106.1

89.4~98.1

84.7~98.2

Matrix

licorice

perilla leaf

safflower

carthamus

hawthorn

patchouli

cinnamon

Spikedlevels

Recoveryranges

75.0~103.1

81.0~105.5

81.9~102.6

86.0~102.8

84.3~100.4

92.3~100.3

72.5~92.4

82.5~106.0

82.5106.5

74.4~91.9

86.3~102.5

84.5~100.2

80.5~98.8

85.0~94.8

84.1~98.6

72.5~91.3

81.2~104.9

81.4~101.8

SN/T4063—2014

AnnexA

(Informative)

Reference conditions of instrumentl)Because the test results depends on the used instrument,it is not possible to give general parametersof mercury detector. Set parameters shall ensure that the mercury content in the samples can be ef-fectively measured parameters are given.The following is proved feasiblea)

Drying temperature:300 ℃

Dryingtime:70s;

Decompositiontemperature:800 CDecomposition time:120 s

Catalytic temperature:600℃:Wait time: 60 s:

Goldamalgamtemperature:600

Goldamalgamtime:12s

Time of record the measurement signal:150 sInletpressureofcarriergas:89.6kPa17.2kPaOutletpressureofcarriergas:2.6kPa~10.3kPa1)

Non-commerical statement:the reference mass parameters in Annex A are accomplished by TELEDYNELeeman Labs Hydra-C,the equipment and its type involved in the standard method is only for reference and notrelated to any commercial aim,and the analysts are encouraged to use equipments of different corporation ordifferent type.

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

出口植物性中药材中汞含量的测定直接进样-冷原子吸收光谱法

Determination of mercury in botanic Chinese medicinal material for export-Directinjection-coldatomicabsorptionspectroscopymethod2014-11-19发布

中华人民共和国

国家质量监督检验检疫总局

2015-05-01实施

本标准按照GB/T1.1—2009给出的规则起草。SN/T4063-—2014

请注意本文件的某些内容可能涉及专利。本文件的发布机构不承担识别这些专利的责任本标准由国家认证认可监督管理委员会提出并归口。本标准起草单位:中华人民共和国重庆出人境检验检疫局,本标准主要起草人:郑国灿、李贤良、朱美文、王晶、张雷、刘毅、陈江、向清华。1范围

出口植物性中药材中汞含量的测定直接进样-冷原子吸收光谱法

本标准规定了植物性中药材中汞含量的直接进样-冷原了吸收光谱测定方法。SN/T4063-—2014bzxZ.net

本标准适用于人参、廿草、大青叶、紫苏叶、菊花、红花、枸杞、山楂、麻黄、藿香、黄柏、肉桂等植物性中药材中汞含量的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。GB/T602化学试剂杂质测定用标准溶液的制备GB/T5330工业用金属丝编织方孔筛网GB/T6682分析实验室用水规格和试验方法3方法提要

样品通过进样器导人测汞仪中,经干燥后热分解,分解后的汞被还原成汞原子,汞原子蒸气在齐化管中进行金汞齐化反应、高温解析后在波长253.65nm处进行测定,按照标准曲线法定量。4试剂和材料

除另有规定外,所用试剂均为优级纯,水为GB/T6682规定的一级水。4.1硝酸:优级纯。

4.210%硝酸溶液:量取100mL硝酸(4.1)用水稀释成1000mL4.3重铬酸钾。

4.4重铬酸钾溶液(1g/L):称取0.1g重铬酸钾(4.3)溶于100mL水中。4.5汞标准储备溶液(1000mg/L):按GB/T602方法配制,或者直接使用有证标准物质。4.6汞标准中间溶液(20mg/L):准确移取2mL汞标准溶液(4.5)于100mL的容量瓶中,加入1ml重铬酸钾溶液(4.4),用硝酸溶液(4.2)定容,混,于室温下存储。4.7汞标准中间溶液(2.0mg/L):准确移取10mL求标准中间溶液(4.6)于100mL的容量瓶中,加入1mL重铬酸钾溶液(4.4),用水定容,混匀。此溶液含汞2.0μg/mL(溶液用时现配)。4.8汞标准工作溶液:分别移取0mL、0.10ml.0.25mL0.50mL、1.50mL、2.50mL、5.00mL、10.00ml15.00mL汞标准中间溶液(4.7)和2.5mL、5.0mL、15.0ml、25.0mL汞标准中间溶液(4.6)于两组100mL的容量瓶中,用水稀释至刻度,混勾。此时标准工作溶液对应的汞浓度分别为0μg/L、2μg/L、5μg/L、10ug/L、30μg/L、50μg/L、100μg/L、200μg/L、300ug/L(低含量系列)和500ug/L、1000μg/L、3000uμg/L5000ug/L(高含量系列)。1

SN/T4063—2014

载气:氧气,纯度≥99.99%。

仪器和设备

5.1测汞仪:配2个吸收池。

5.2样品舟:材质为镍或相当者。分析天平:感量0.1mg。

移液器:量程10μl~200μ。

6试样的制备与保存

6.1取有代衣性样约200g,用分析研磨机将样品粉摩成细粉(95%以上粉末能通过符合GB/T5330中R40/3系列孔径为0.25mm的标准试验筛),装人洁净容器,存储于干燥器中。6.2制样操作过程中应防止样品受到污染或发生残留物含量的变化。7测定步骤

7.1测定

称取0.1g(精确至0.0001g)试样于样品舟中.参照附录A的仪器条件进行测定。7.2标准曲线

分别吸取100μL标准工作溶液(4.8)于两组样品舟中,此时各样品舟中对应的汞的质量分别为0ng、0.2ng、0.5ng、1ng、3ng、5ng、10ng、20ng、30ng(低含量系列)和50ng、100ng、300ng、500ng(高含量系列),按照含量由低到高的顺序,参照附录A条件在波长253.65nm处测定其吸光度。以相应汞的质量(ng)为横坐标,吸光度为纵坐标,绘制两条标准工作曲线。7.3注意事项

在仪器的重要部件没有更换时,一般无需进行标准曲线的重新绘制。测试前应使用与样品具有7.3.1

相当水平的汞标样进行校正。

7.3.2如果样品中汞含量超出工作曲线的范围,可减少称样量进行测定。8结果计算和表述

按式(1)计算试样中汞的含量:式中:

X=mx1000

maX1000

试样中汞含量,单位为微克每千克(ug/kg);从工作曲线上查得的汞的质量,单位为纳克(ng);样品质量,单位为克(g)。

取两次平行测定结果的算术平均值为试样的最终结果。2

.(1)

-TKAONKAca

定量限和回收率

定量限

本方法定量限为10μg/kg。

回收率

各种基质的添加水平及回收率范围见表1。表1各种基质的添加水平及回收率范围基质

大青叶

添加水平

Iig/kg

回收率范围

72.5~-91.3

80.9~-99.7

91.8~99.6

96.0~-94.9

81.9~105.6

89.8~97.6

84.4~100.3

82.9-104.

81.5--106.1

89.4~-98.1

84.7--98.2

紫苏畔

SN/T4063—2014

回收率范围

75.0~103.1

81.0~105.5

81.9102.6

86.0--102.8

84.3~100.4

92.3~100.3

82.5~106.0

82.5-~106.5

74.4--91.9

86.3102.5

84.5~-100.2

80.5~98.8

85.0~94.8

81.2~104.9

81.4~-101.8

-TrKAONiKAca

SN/T4063—2014

附录A

(资料性附录)

仪器参考条件”

由于测试结果取决于所使用仪器,因此不可能给出测汞仪的通用参数。设定的参数应保证样品中的汞含量能够得到有效的测定。下列给出的参数证明是可行的:a)

干燥温度:300℃;

干燥时间:70S;

分解温度:800℃:

分解时间:120S;

催化温度:600℃;

等待时间:608

金汞齐温度:600℃;

汞齐化时间:125;

记录测量信号时问:1505;

载气输人压力:89.6kPa~-117.2kPa;载气输出压力2.6kPa~10.3kPa。1)非商业性声明:附录A所列参考条件是在TELEDYNELeemanLabsHydra-C型全白动测汞仪上完成的,此次列出试验用仪器型号仪为提供参考,并不涉及商业目的,鼓励标准使用者尝试不同厂家或型号的仪器,4

riKAoNiiKAca

Foreword

This standard was drafted according to GB/T 1.1-2009SN/T4063-—2014

Please note that some of the elements of this document may be involved in patent,issued the docu-ment does not assume the responsibility identification of these patents.This standard was proposed by and was under the charge of National Regulatory Commission for Cer-tificationandAccreditationofthePeople'sRepublicof China.The standard was drafted by Chongqing Entry-Exit Inspection and Quarantine Bureau of the People'sRepublicof China.

This standard was mainly drafted by Zheng Guocan,Li Xianliang,Zhu Meiwen,Wang JingZhang Lei.LiuYi,ChenJiang,XiangQinghuaNote:This English version,a translation from theChinesetextis solely forguidance.-rKAoNiKAca

SN/T4063—2014

DeterminationofmercuryinbotanicChinesemedicinal materialforexportDirect injection-coldatomic absorption spectroscopy method1Scope

The standard specifies the method of determination of mercury in botanic Chinese medicinal materialfor export by direct injection-colddatomicabsorption spectroscopyThis standard is applicable to the determination of mercury in ginseng,licorice,folium isatidis,perillaleaf,chrysanthemum,safflower,Chinesewolfberry.hawthorn.ephedra,patchouli,cortexphellodendri,cinna-mon.

2 Normative reference

Thefollowingdocumentsarenecessaryforthisstancshall applytothis standard.Forundated reference

ordatedreferences,onlydatededitionss.the latest edition of the normative document(in-cludingsubsequentamendments)isreferredtoapplies.GB/T602

GB/T5330

GB/T6682

Chenmical reagent

rd solutionsforimpurity

Preparations of standa

Industrialwovenmetal

re cloth(square opening

Waterforanalytical laboratory use3Principle

Specificationand

testmethod

The sample was guided into the the mercury analyzer through the injector,drying and thermal decomposition,mercury which decomposited was reduced to atomic mercury vapor,and was reacted ingold amalgam,and.quantitatied at the wavelengthof 253.65 nm after resolution underhigh tempera-ture,according to the standard curve4Reagents and materials

Unless specified,all reagents shall be of analytical grade;Water\is the first water prescribed byGB/T6682

-TKAONiKAca

4.1 Nitric acid: GR.

SN/T4063-—2014

4.2 Nitric acid solution(10%):dilute 100 mL nitric acid(4.1) to 1000 mL withwater.4.3Potassiumdichromate.

4.4Potassium dichromate solution (1g/L):Dilute0.1gPotassiumdichromate(4.3)to100mLwithwater.

4.5Mercury standard solution(1000mg/L):Prepared by GB/T602method,oruse certificated ref-erencematerial.

4.6Mercury standard middle solution(20 mg/LAccurately

measured2mLthestandard solution(4.5)in an100 mL volumetric flask andPotassium dichromate solution(4.4) andadded1ml

dissloved withnitric acid solution (4.toforma

standard solution was stored at the room tempeddle standardsolutionof 20 mg/L.Themiddle4.7Mercury standard middle solution(2.0 mg/L):Accuratelymeasured 10mL themiddle standardsolution(4.6))inan10omLvolumetricflaskandaddedm

umdichromatesolution(4.4)andotassu

dissloved withwatertoformamiddlestandard solution of2.Oμg/L4.8 Mercury standard working solution:Respectivelymeasured0mL.0.10mL0.25mL,0.50mL,mL.15.00mL

1.50mL.2.50mL,5.00mL,10.00

standardmiddlesolution(4.7)and2.5mL,mercury

in differentvolumetric flaskanddi-5.0mL,15.0mL,25.0mLmercurystandardmiddlesolution(4.6)luted to 100 mL with water.the conct50μg/L100μg/.200μg/L,300

5000μg/L(highcontentrange).4.9

Carriergas:Oxygen.purity≥99.995

Apparatus and equipment

2ugL.5μg/L,10μg/L,30μg/L,swereoug/L

rntrations

content

Mercury analyzer:With2absorption cell.range)

Sample boats:materials for nickel or equivalent.5.3E

Electronicbalance(0.1mg)

5.4Pipettes:the rangeof10μL~200μL.and500μg/L1000μg/L3000ug/

SN/T4063—2014

Sample preparation and storage6.1 Take a representative sample of about 200 g,crushed with grinding machine (which more than95%p0wder can through the0.25mm standardtest sieveofGB/T5330R40/3series).put intoaclean container,stored in a desiccator.6.2Certain measures shall be taken to prevent contamination of the samples or decomposition ofthe residues during the sample preparation procedure.7

Analytical procedure

Determination

Weigh 0.1 g (accurate to 0.000 1g) sample in the sample boat,and determined refer to instrumentconditionsinappendixA

Standard curve

Respectively absorb100μL standard working solution(4.8)in sampleboats,the contentsof mercurywere0ng.0.2ng.0.5ng,1ng.3ng.5ng.10ng.20ng,30ng(lowcontentrange)and50ng.100ng,300 ng.500 ng (high content range),then determined refer to instrument conditions in appendix Afrom low to high,drawing two standard working curve.Corresponding to the mercury mass (ng) asabscissa,absorbanceasordinate.7.3Note

7.3.1In general,the cuve don't need to draw,if the important component in the instrument withoutreplacement,themercury standard solution was used to calibrate before determination.Sampleweightcanbe reducedif mercurycontentbeyond thework curve7.3.2

Calculationand expression of result8

Calculatingthecontentof mercuryaccordingtotheformula(1)X=

where:

m×1000

m。×1000

thecontentofmercuryinthetestsample,ug/kg...1)

thecontentofmercurycheckedfromworkingcurve.ng;sampleweightg

Two parallel determinations on the average as the final results of the sampleLimitofquantification(LoQ)andrecovery9.1

TheLimitofquantificationwas10μg/kg。9.2

Recovery

The recoveries ranges of mercury in everymatrix were listed in table1.SN/T4063—2014

Tablel-The spiked levels andrecoveriesranges of mercuryineverymatrixMatrix

ginseng

folium

isatidis

chrysanthe

Chinese

wolfberry

ephedra

cortex

phellodendri

Spikedlevels

Recovery ranges

72.5~91.3

80.9~99.7

91.8~99.6

85.0~106.3

83.3~107.1

85.0~93.8

96.0~94.9

81.9~105.6

89.8~97.6

91.5~109.8

84.4~100.3

80.0~101.6

75.8~89.3

81.3~99.4

82.9~104.1

81.5~106.1

89.4~98.1

84.7~98.2

Matrix

licorice

perilla leaf

safflower

carthamus

hawthorn

patchouli

cinnamon

Spikedlevels

Recoveryranges

75.0~103.1

81.0~105.5

81.9~102.6

86.0~102.8

84.3~100.4

92.3~100.3

72.5~92.4

82.5~106.0

82.5106.5

74.4~91.9

86.3~102.5

84.5~100.2

80.5~98.8

85.0~94.8

84.1~98.6

72.5~91.3

81.2~104.9

81.4~101.8

SN/T4063—2014

AnnexA

(Informative)

Reference conditions of instrumentl)Because the test results depends on the used instrument,it is not possible to give general parametersof mercury detector. Set parameters shall ensure that the mercury content in the samples can be ef-fectively measured parameters are given.The following is proved feasiblea)

Drying temperature:300 ℃

Dryingtime:70s;

Decompositiontemperature:800 CDecomposition time:120 s

Catalytic temperature:600℃:Wait time: 60 s:

Goldamalgamtemperature:600

Goldamalgamtime:12s

Time of record the measurement signal:150 sInletpressureofcarriergas:89.6kPa17.2kPaOutletpressureofcarriergas:2.6kPa~10.3kPa1)

Non-commerical statement:the reference mass parameters in Annex A are accomplished by TELEDYNELeeman Labs Hydra-C,the equipment and its type involved in the standard method is only for reference and notrelated to any commercial aim,and the analysts are encouraged to use equipments of different corporation ordifferent type.

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。