SN/T 4675.27-2016

基本信息

标准号: SN/T 4675.27-2016

中文名称:出口葡萄酒碱性灰分的测定

标准类别:商检行业标准(SN)

标准状态:现行

出版语种:简体中文

下载格式:.zip .pdf

下载大小:4899059

标准分类号

关联标准

出版信息

相关单位信息

标准简介

SN/T 4675.27-2016.Determination of alkaline ash in wine for export.

1范围

SN/T 4675.27规定了葡萄酒中碱性灰分的测定方法。

SN/T 4675.27适用于葡萄酒中碱性灰分的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T601化学试剂标准滴定溶液的制备

GB/T6682分析实验室用水规格和试验方法

3方法提要

灰分溶解于标准酸滴定溶液中,过量的酸以碱标准滴定溶液滴定.根据碱的消耗量乘以换算系数即为灰分的碱度。

4试剂和材料

4.1盐酸标准滴定溶液(0.1000mol/L)或硫酸标准滴定溶液(0.0500mol/L):按GB/T601进行配制及标定。

4.2氢氧化钠标准 滴定溶液(0.100 0 mol/L) :按GB/T 601进行配制及标定。

4.3甲 基橙指示剂(0.1%):称取0.1 g甲基橙(4.1),用少量水溶解,全部转移至100 mL容量瓶中,用水定容至刻度。

5仪器和设备

5.1恒温水浴锅。

5.2分析天平:感量为0.1 mg。

5.3加热板。

5.4 干燥器(内有干燥剂)。

5.5铂坩埚或瓷坩埚。

5.6马弗炉。

1范围

SN/T 4675.27规定了葡萄酒中碱性灰分的测定方法。

SN/T 4675.27适用于葡萄酒中碱性灰分的测定。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T601化学试剂标准滴定溶液的制备

GB/T6682分析实验室用水规格和试验方法

3方法提要

灰分溶解于标准酸滴定溶液中,过量的酸以碱标准滴定溶液滴定.根据碱的消耗量乘以换算系数即为灰分的碱度。

4试剂和材料

4.1盐酸标准滴定溶液(0.1000mol/L)或硫酸标准滴定溶液(0.0500mol/L):按GB/T601进行配制及标定。

4.2氢氧化钠标准 滴定溶液(0.100 0 mol/L) :按GB/T 601进行配制及标定。

4.3甲 基橙指示剂(0.1%):称取0.1 g甲基橙(4.1),用少量水溶解,全部转移至100 mL容量瓶中,用水定容至刻度。

5仪器和设备

5.1恒温水浴锅。

5.2分析天平:感量为0.1 mg。

5.3加热板。

5.4 干燥器(内有干燥剂)。

5.5铂坩埚或瓷坩埚。

5.6马弗炉。

标准图片预览

标准内容

中华人民共和国出入境检验检疫行业标准SN/T4675.27—2016

出口葡萄酒碱性灰分的测定

Determination of alkaline ash in wine for export2016-12-12发布

中华人民共和国

国家质量监督检验检疫总局

西涂黑夜真价

2017-07-01实施

SN/T4675《出口葡萄酒质量安全分析方法》共分为30个部分:SN/T4675.1

SN/T4675.2

SN/T4675.3

SN/T 4675.4

SN/T4675.5

SN/T4675.6

SN/T 4675.7

SN/T 4675.8

SN/T4675.9

SN/T4675.10

SN/T 4675.11

SN/T4675.12

SN/T 4675.13

SN/T-4675.14

SN/T4675.15

SN/T4675.16

SN/T4675.17

出口葡萄酒中甘油的测定酶法:出口葡萄酒中2.3丁二醇的测定气相色谱法;出口葡萄酒中乙醇稳定碳同位素比值的测定;出口葡萄酒中乳酸的测定酶法;出口葡萄酒中有机酸的测定离子色谱法:出口葡萄酒中葡萄糖、果糖和蔗糖的测定;出口葡萄酒中乙醛的测定气相色谱-质谱法;出口葡萄酒中5-羟甲基糠醛的测定液相色谱法;出口葡萄酒中二甘醇的测定气相色谱-质谱法:SN/T4675.27—2016

出口葡萄酒中赭曲霉毒素A的测定液相色谱质谱/质谱法;出口葡萄酒中7种花色苷的测定超高效液相色谱法;出口葡萄酒中溶菌酶的测定液相色谱法;出口葡萄酒中2,4,6-三氯苯甲醚残留量的测定气相色谱-质谱法;出口葡萄酒中纳他霉素的测定液相色谱质谱/质谱法;出口葡萄酒中水杨酸、脱氢乙酸和对氯苯甲酸的测定液相色谱法;出口葡萄酒中富马酸的测定液相色谱-质谱/质谱法;出口葡萄酒中丁基锡含量的测定气相色谱-质谱/质谱法;SN/T 4675.18

SN/T4675.19

SN/T4675.20

SN/T4675.21

SN/T4675.22

SN/T 4675.23

SN/T 4675.24

SN/T4675.25

出口葡萄酒中二硫代氨基甲酸酯残留量的测定顶空气相色谱法;出口葡萄酒中钠、镁、钾、钙、铬、锰、铁、铜、锌、砷、硒、银、锅、铅的测定;出口葡萄酒中稀土元素的测定电感耦合等离子体质谱法:出口葡萄酒中可溶性无机盐的测定离子色谱法:出口葡萄酒中总二氧化硫的测定比色法;出口葡萄酒及葡萄汁中氨氮的测定连续流动分析仪法;出口葡萄酒福林-肖卡指数的测定,分光光度计法;出口葡萄酒颜色的测定CIE1976(Lab)色空间法;SN/T4675.26

出口葡萄酒浊度的测定散射光法;SN/T 4675.27

SN/T4675.28

SN/T4675.29

出口葡萄酒碱性灰分的测定;

出口葡萄酒细菌、霉菌及酵母的计数:出口葡萄酒中酒香酵母检验实时荧光PCR法;出口葡菊酒中拜氏接合酵母检验实时荧光PCR法。SN/T4675.30

本部分为SN/T4675的第27部分。本部分按照GB/T1.1一2009给出的规则起草。本部分等同国际葡萄与葡萄酒组织(OIV)的方法OIV-MA-AS2-04《葡萄酒灰分》(AshofWines)和部分修改采用OIV-MA-AS2-05《葡萄酒碱性灰分滴定法》(AlkalinityofAshofWinesTitrimetricMethod)。本部分在技术内容上与两方法基本一致,但考虑到我国标准本身的特点及汉语表达习惯,对OIV的方法MA-AS2-05的个别内容作了技术性修改,修改的主要内容为:增加了瓷埚;

SN/T4675.27—2016

增加了盐酸标准滴定溶液(0.1000mo1/L):X(10-V)X0.069X1000

—增加了公式一

请注意本文件的某些内容可能涉及专利,本文件的发布机构不承担识别这些专利的责任。本部分由国家认证认可监督管理委员会提出并归口。本部分起草单位:中华人民共和国中山出入境检验检疫局、中华人民共和国黄埔出人境检验检疫局、中华人民共和国广东出入境检验检疫局本部分主要起草人:冯雪雅、李蓉、田玲、李云松、李浩洋、谢丽芳、梁健宇、何杏宗、刘青、李志勇。1范围

出口葡萄酒碱性灰分的测定

SN/T4675的本部分规定了葡萄酒中碱性灰分的测定方法。本部分适用于葡萄酒中碱性灰分的测定,2规范性引用文件

SN/T4675.27—2016

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注目期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。GB/T601化学试剂标准滴定溶液的制备GB/T6682分析实验室用水规格和试验方法3方法提要

灰分溶解于标准酸滴定溶液中,过量的酸以碱标准滴定溶液滴定、根据碱的消耗量乘以换算系数即为灰分的碱度。

4试剂和材料

除另有规定外,所用试剂均为分析纯,试验用水为GBT6682规定的4.1甲基橙(C4HN,SO.Na)。

盐酸(HCI)。

硫酸(H,SO)。

氢氧化钠(NaOH)。

4.5盐酸标准滴定溶液(0.1000mol/L)或硫酸标准滴定溶液(0.050mol/L):按GB/T601进行配制及标定。

4.6氢氧化钠标准滴定溶液(0.1000mol/L):按GB/T601进行配制及标定。4.7甲基橙指示剂(0.1%)称取0.1g甲基橙(4.1),用少量水溶解,全部转移至100mL容量瓶中,用水定容至刻度。

仪器和设备

恒温水浴锅。

分析天平:感量为0.1mg。

加热板。

干燥器(内有干燥剂)。

5.5铂埚或瓷埚。

马弗炉。

TTKAONTKAca

SN/T4675.27-2016

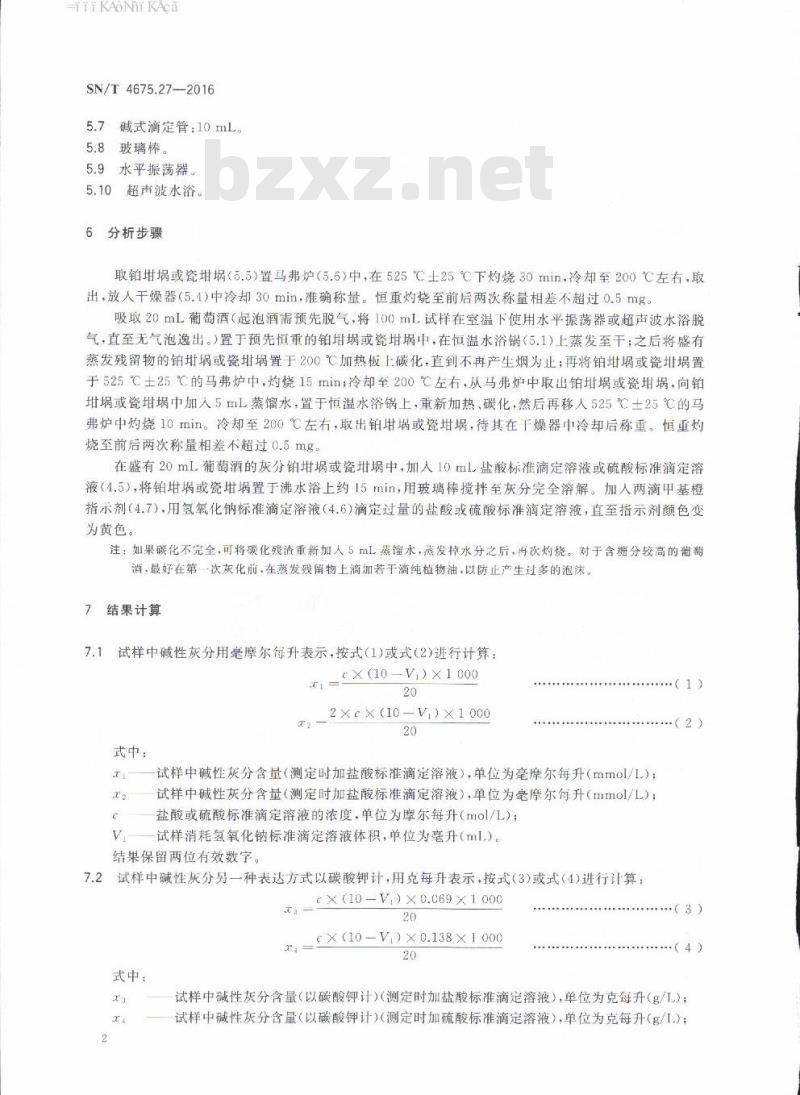

5.7碱式滴定管:10mL。

5.8玻璃棒。

5.9水平振荡器。

5.10超声波水浴。

6分析步骤

取铂埚或瓷(5.5)置马弗炉(5.6)中,在525℃土25℃下灼烧30min,冷却至200℃左右,取出,放人干燥器(5.4)中冷却30min,准确称量。恒重灼烧至前后两次称量相差不超过0.5mg。吸取20mL葡萄酒(起泡酒需预先脱气,将100mL试样在室温下使用水平振荡器或超声波水浴脱气,直至无气泡逸出。)置于预先恒重的铂埚或瓷埚中,在恒温水浴锅(5.1)上蒸发至干;之后将盛有蒸发残留物的铂埚或瓷埚置于200℃加热板上碳化:直到不再产生烟为止;再将铂甘或瓷置于525℃土25℃的马弗炉中,灼烧15min;冷却至200℃左右,从马弗炉中取出铂埚或瓷,向铂甘或瓷埚中加入5mL蒸馏水,置于恒温水浴锅上,重新加热、碳化,然后再移人525℃±25℃的马弗炉中灼烧10min。冷却至200℃左右,取出铂埚或瓷,待其在干燥器中冷却后称重。恒重灼烧至前后两次称量相差不超过0.5mg。在盛有20mL葡萄酒的灰分铂埚或瓷甘埚中,加人10ml盐酸标准滴定溶液或硫酸标准滴定溶液(4.5),将铂或瓷置于沸水浴上约15min,用玻璃棒搅拌至灰分完全溶解。加人两滴甲基橙指示剂(4.7),用氢氧化钠标准滴定溶液(4.6)滴定过量的盐酸或硫酸标准滴定溶液,直至指示剂颜色变为黄色。

注:如果碳化不完全,可将碳化残清重新加人5mL燕馏水,燕发掉水分之后,再次灼烧。对于含糖分较高的葡葡酒,最好在第一次灰化前,在蒸发残留物上滴加若干滴纯植物油,以防止产生过多的泡沫。7结果计算

7.1试样中碱性灰分用毫摩尔每升表示,按式(1)或式(2)进行计算:X(10-V))×1 000

式中:

2Xc(10-V)X1000

试样中碱性灰分含量(测定时加盐酸标准滴定溶液),单位为毫摩尔每升(mmol/L);试样中碱性灰分含量(测定时加盐酸标准滴定溶液),单位为毫摩尔每升(mmol/L);盐酸或硫酸标准滴定溶液的浓度,单位为摩尔每升(mol/L);试样消耗氢氧化钠标准滴定溶液体积,单位为毫升(mL)。V

结果保留两位有效数字。免费标准下载网bzxz

2试样中碱性灰分另一种表达方式以碳酸钾计,用克每升表示,按式(3)或式(4)进行计算:7.2

cX10-V)X0.069X1000

;=X(10V)0.138×1 000

式中:

(2)

(3)

·(4

试样中碱性灰分含量(以碳酸钾计)(测定时加盐酸标准滴定溶液),单位为克每升(g/L);试样中碱性灰分含量(以碳酸钾计)(测定时加硫酸标准滴定溶液),单位为克每升(g/L):-KAoNiKAca

盐酸或硫酸标准滴定溶液的浓度,单位为摩尔每升(mol/L);试样消耗氢氧化钠标准滴定溶液体积,单位为毫升(mL);0.069

SN/T4675.27—2016

与1.00mL盐酸标准滴定溶液[c(HCI)=1.000mol/L]相当的碳酸钾的质量,单位为克(g):

与1.00mL硫酸标准滴定溶液[c(H,SO,)=1.000mol/L]相当的碳酸钾的质量,单位为克(g)。

结果保留两位有效数字。

8重复性

以两次平行测定结果的算术平均值作为测定结果,两次平行测定结果的绝对差值不得超过其算术平均值的10%。

KAoNiKAca

SN/T4675.27—2016

Foreword

Standard(SN/T4675)\Methodsofexportwineanalysis\includes30parts:SN/T4675.1Determinationofglycerol inwineforexport-Enzymaticmethod;-SN/T4675.2Determinationof2,3-butanediolinwineforexport-GCmethod;-SN/T 4675.3 Determination of stable carbon isotope ratio of ethanol in wineforexport;SN/T4675.4Determinationof lacticacid inwineforexport-SN/T4675.5DeterminationoforganicacidinwineforexEnzymaticmethod;

port-lonchromatographymethod;-SN/T4675.6Determinationofglucose.fructoseand sucrose inwine forexport;-SN/T4675.7 Determinationofacetaldehyde inwineforexport--GC/MSmethod;—SN/T4675.8Determinationof5-hydroxymeethylfurfural inwinefor export-HPLC method;—SN/T4675.9Determinationof diethyleneinwineforexport--GC/MSmethod;

Ainwine for

HPLC/MS/MSmethod;

-SN/T4675.10Determinationofochratoxinexport-

Determination of7anthyocy

SN/T4675.11D

UHPLCmethod;

-SN/T4675.12Determination of lysozyme in wine for export-HPLCmethod;

—SN/T4675.13Determinationof2,4,6-trichloroanosoleinwineforexport-GC/MSmethod;-SN/T4675.14Determinationofnatamycineinwineforexport—HPLC/MS/MSmethod;SN/T4675.15Determination of salicylic acid,dehydroacetic acid and 4-chlorobenzoic acid in wineforexport-HPLCmethod:

—SN/T 4675.16 Determination of fumaric acid in wine for export-HPLC/MS/MS method;SN/T4675.17Determinationofbutyltincompoundsinwineforexport-GC/MS/MSmethod;SN/T4675.18Determinationofdithiocarbamates(salt)residuesinwinefor export-Headspace4

KAOKAca

GCmethod;

SN/T4675.27—2016

-SN/T4675.19Determinationof sodium,magnesium,potassium,calcium,chromium,manganese,ironcopperzinc,arsenic,selenium,silvercadmiumandleadinwineforexportSN/T4675.20Determinationof rare-earthelementsinwineforexport-ICP-MSmethod;SN/T4675.21

method

Determination of soluble inorganic salts in wine for export-lon chromatography-SN/T4675.22Determination oftotal sulfurdioxide in wineforexport-Colorimetricmethod;-SN/T4675.23Determination ofammoniumnitrogen in wineand grape juiceforexport-Continu-ousflowanalysis(CFA)method:

-SN/T4675.24Determinationof Folin&Ciocalteu indexmethod;

—SN/T4675.25

spacesystem;

fwineforexport-Spectrophotometryexport-CIELabcolor

Determination of chromatic characteristics of winefor—SN/T4675.26

Determination of turbidity

fwineforexport-Diffused radiationmethod-SN/T4675.27Determinationofalkalineashofwineforexpont:

-SN/T4675.28Method for enumeration of colony-forming units of yeasts,moulds and bacteria incork stoppers and wine for export;—SN/T4675.29Determinationofbrettanomycesin wineforexport

-SN/T4675.30

eal-timePCRmethod;

Determination of zygosaccharomyces baili in wine for export-Real-time PCRThis part is part27of the standardThispart isdrafted accordingtoGB/T1.1—2009This part completely adopted the method of Organization of International Vine and wine (OlV) MA-AS2-04,\Ashof Wines\and modified MA-As2-05\Alkalinity of Ashof WinesTitrimetricMethod”.Thetechnical contentwas the sameexcept for sometechnical changesas follows:-Porcelaincruciblewasincreased:5

TKAoNIKAca

SN/T4675.27—2016

—Hydrochloricacid standard titration solution(0.1000mol/L)was increased;-Formulaofx3

c×10-V,)0.069x1000

wasincreased

Please note that some of the content of the standard may involvepatents.Publication of the presentstandard does not bear the responsibility of identifying these patents.This part was proposed by and was under the jurisdiction of Certification and Accreditation Adminis-trationofthePeople'sRepublicofChina.This part was drafted by Zhongshan Entry-Exit Inspection and QuarantineBureau of thePeople's Republic of China,Huangpu Entry-Exit Inspection and Quarantine Bureau of the People's Republic ofChina and Guangdong Entry-Exit Inspection and Quarantine Bureauof thePeople's Republic of China.Themain drafters of this part were Feng Xueya,Li Rong,Tian Ling,Li Yunsong,Li Haoyang,Xie Lifang,LiangJianyu,HeXingzong,Liu Qingand Li Zhiyong.1

SN/T4675.27—2016

Determinationof alkalineashinwineforexportScope

This part specifies the method for the determination of alkalinity ash in wine.This part is applicable to the determination of alkalinityash in wine.2

Quotednormativedocuments

The following referenced documents are indispensable for the application of this document.Fordated references,only edition cited applies.For undated references,the latest edition of the refer-enced document(including any amendments)applies.GB/T601

Chemical reagent-Preparations of standardvolumentric solutions2Water foranalytical laboratoryuse-Specification and testmethods.GB/T6682

Principle

The ash is dissolved in acid standard titration solution,the excess acid solution is determined by Al-kali standard titration solution,the consumption of alkali content multiplied by the conversion coeffi.cientfactoristhealkalinityof ash4

Reagents and materials

Unless others specified,the reagents should be analytical pure. And the water should accord withGB/T6682

Methylorange(CiaH1N,SO,Na).

Hydrochloric acid (HCl),

Sulfuricacid(H,SO4).

Sodiumhydroxide(NaOH)

SN/T4675.27—2016

4.5Hydrochloric acid standard titration solution (o.1000 mol/L)or sulfuric acid standard solution(o.050omol/L):PreparationandcalibrationofGB/T601.4.6Sodium hydroxide standard titration solution(0.1000 mol/L):Preparation and calibration ofGB/T601.

4.7Methylorange indicator(0.1%)Take0.1gmethylorange(4.1),dissolved with a small amountofwater,transferredtoavolumetricflask(100mL),diluteto100mL.5Apparatus and equipment

5.1Thermostaticbath.

5.2Analysis balance:sensitive to0.1mg.5.3 Heatingplate.

Dryer(desiccant).

5.5 Platinum crucible or porcelain crucible.Mufflefurnace.

Alkali Burette:10 mL

Glass rod.

5.9Horizontal oscillatortuble.5.10

Ultrasonic bath.

6Analyticalprocedure

Put platinum crucible or porcelain crucible(5.5)in a muffle furnace (5.6),burning for 30 min at525℃±25,cooling to200,removeand place ina dryer(5.4)coolingfor30 min,accuratelyweighing.Burning to constant weight,the weight difference of before and after burning times is un-der0.5mg.

Pipette20 mL wine(sparkling wine need to pre-degas,100 mL sample willbe degassedbyhorizontaloscillator or ultrasonic waveat room temperature until no bubles) into the previously platinum cruci-ble or porcelain crucible(constant weight),evaporate sample wine to dry on the Thermostatic bath8

SN/T4675.27—2016

(5.1),then carbonizing the evaporating residues on the heating plate at 20o ℃,until no smog ap-peared.Put the crucible into the furnace and burn for 15min at 525℃ ±25℃,cooling to 200 ℃,andtake out the crucible and add 5 mL water,and put into Thermostatic bath(5.1),then re-heating,re-carbonizing.then put into muffle furnace,burning for 10 mins,cooling to 20o C,take out platinumcrucible or porcelain crucible,then weigh it after being cooled in dryer.Burning to constant weight,the weight difference of before and after burning times is under o.5mg.Add 10 mL hydrochloric acid standard titration solution or sulfuric acid standard solution(4.5) to theash from 20 mL of wine in the platinum crucible or porcelain crucible.Place the crucible on the boilingwater-bathforabout15

irringthesolutionbyglassroduntil theashwastotallydissolved.Add two drops of methyl orange solution (4.7)and titrate the excess hydrochloric acid orsulfuric acid against sodium hydroxide standard titration solution(4.6)until the color of the indicatorchangestoyellow.

tcompletely.canre-add5mLdistilledwaterthenevaporatedwa-Note:if the carbonization was notters,burning again. For some sample wine which include high sugar content.when firstlycarbonizing,itwillbebettertodropsomepla7

Expression of results

n samplewineforpreventingfoam.7.1In the sample,the alkaline ash contentexpressed in milliequivalents per liter was calculated byformula(1)orformula(2)

×1000

2xC×(10-V)×1000

Where:

·(2)

x,alkaline ash content in the sample,(determination of the hydrochloric acid standard titration so-lution)mmol/L;

X2the alkalineash content in the sample,(determination of the sulfuric standard titration solution)mmol/L:

c the concentration of the standard titration solution of hydrochloric acid or sulfuric acid,mol/L;V,-thevolumeof the sampleconsumptionof sodiumhydroxidestandardtitrationsolution,mL;The result is kept to two decimal places.9

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。

出口葡萄酒碱性灰分的测定

Determination of alkaline ash in wine for export2016-12-12发布

中华人民共和国

国家质量监督检验检疫总局

西涂黑夜真价

2017-07-01实施

SN/T4675《出口葡萄酒质量安全分析方法》共分为30个部分:SN/T4675.1

SN/T4675.2

SN/T4675.3

SN/T 4675.4

SN/T4675.5

SN/T4675.6

SN/T 4675.7

SN/T 4675.8

SN/T4675.9

SN/T4675.10

SN/T 4675.11

SN/T4675.12

SN/T 4675.13

SN/T-4675.14

SN/T4675.15

SN/T4675.16

SN/T4675.17

出口葡萄酒中甘油的测定酶法:出口葡萄酒中2.3丁二醇的测定气相色谱法;出口葡萄酒中乙醇稳定碳同位素比值的测定;出口葡萄酒中乳酸的测定酶法;出口葡萄酒中有机酸的测定离子色谱法:出口葡萄酒中葡萄糖、果糖和蔗糖的测定;出口葡萄酒中乙醛的测定气相色谱-质谱法;出口葡萄酒中5-羟甲基糠醛的测定液相色谱法;出口葡萄酒中二甘醇的测定气相色谱-质谱法:SN/T4675.27—2016

出口葡萄酒中赭曲霉毒素A的测定液相色谱质谱/质谱法;出口葡萄酒中7种花色苷的测定超高效液相色谱法;出口葡萄酒中溶菌酶的测定液相色谱法;出口葡萄酒中2,4,6-三氯苯甲醚残留量的测定气相色谱-质谱法;出口葡萄酒中纳他霉素的测定液相色谱质谱/质谱法;出口葡萄酒中水杨酸、脱氢乙酸和对氯苯甲酸的测定液相色谱法;出口葡萄酒中富马酸的测定液相色谱-质谱/质谱法;出口葡萄酒中丁基锡含量的测定气相色谱-质谱/质谱法;SN/T 4675.18

SN/T4675.19

SN/T4675.20

SN/T4675.21

SN/T4675.22

SN/T 4675.23

SN/T 4675.24

SN/T4675.25

出口葡萄酒中二硫代氨基甲酸酯残留量的测定顶空气相色谱法;出口葡萄酒中钠、镁、钾、钙、铬、锰、铁、铜、锌、砷、硒、银、锅、铅的测定;出口葡萄酒中稀土元素的测定电感耦合等离子体质谱法:出口葡萄酒中可溶性无机盐的测定离子色谱法:出口葡萄酒中总二氧化硫的测定比色法;出口葡萄酒及葡萄汁中氨氮的测定连续流动分析仪法;出口葡萄酒福林-肖卡指数的测定,分光光度计法;出口葡萄酒颜色的测定CIE1976(Lab)色空间法;SN/T4675.26

出口葡萄酒浊度的测定散射光法;SN/T 4675.27

SN/T4675.28

SN/T4675.29

出口葡萄酒碱性灰分的测定;

出口葡萄酒细菌、霉菌及酵母的计数:出口葡萄酒中酒香酵母检验实时荧光PCR法;出口葡菊酒中拜氏接合酵母检验实时荧光PCR法。SN/T4675.30

本部分为SN/T4675的第27部分。本部分按照GB/T1.1一2009给出的规则起草。本部分等同国际葡萄与葡萄酒组织(OIV)的方法OIV-MA-AS2-04《葡萄酒灰分》(AshofWines)和部分修改采用OIV-MA-AS2-05《葡萄酒碱性灰分滴定法》(AlkalinityofAshofWinesTitrimetricMethod)。本部分在技术内容上与两方法基本一致,但考虑到我国标准本身的特点及汉语表达习惯,对OIV的方法MA-AS2-05的个别内容作了技术性修改,修改的主要内容为:增加了瓷埚;

SN/T4675.27—2016

增加了盐酸标准滴定溶液(0.1000mo1/L):X(10-V)X0.069X1000

—增加了公式一

请注意本文件的某些内容可能涉及专利,本文件的发布机构不承担识别这些专利的责任。本部分由国家认证认可监督管理委员会提出并归口。本部分起草单位:中华人民共和国中山出入境检验检疫局、中华人民共和国黄埔出人境检验检疫局、中华人民共和国广东出入境检验检疫局本部分主要起草人:冯雪雅、李蓉、田玲、李云松、李浩洋、谢丽芳、梁健宇、何杏宗、刘青、李志勇。1范围

出口葡萄酒碱性灰分的测定

SN/T4675的本部分规定了葡萄酒中碱性灰分的测定方法。本部分适用于葡萄酒中碱性灰分的测定,2规范性引用文件

SN/T4675.27—2016

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注目期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。GB/T601化学试剂标准滴定溶液的制备GB/T6682分析实验室用水规格和试验方法3方法提要

灰分溶解于标准酸滴定溶液中,过量的酸以碱标准滴定溶液滴定、根据碱的消耗量乘以换算系数即为灰分的碱度。

4试剂和材料

除另有规定外,所用试剂均为分析纯,试验用水为GBT6682规定的4.1甲基橙(C4HN,SO.Na)。

盐酸(HCI)。

硫酸(H,SO)。

氢氧化钠(NaOH)。

4.5盐酸标准滴定溶液(0.1000mol/L)或硫酸标准滴定溶液(0.050mol/L):按GB/T601进行配制及标定。

4.6氢氧化钠标准滴定溶液(0.1000mol/L):按GB/T601进行配制及标定。4.7甲基橙指示剂(0.1%)称取0.1g甲基橙(4.1),用少量水溶解,全部转移至100mL容量瓶中,用水定容至刻度。

仪器和设备

恒温水浴锅。

分析天平:感量为0.1mg。

加热板。

干燥器(内有干燥剂)。

5.5铂埚或瓷埚。

马弗炉。

TTKAONTKAca

SN/T4675.27-2016

5.7碱式滴定管:10mL。

5.8玻璃棒。

5.9水平振荡器。

5.10超声波水浴。

6分析步骤

取铂埚或瓷(5.5)置马弗炉(5.6)中,在525℃土25℃下灼烧30min,冷却至200℃左右,取出,放人干燥器(5.4)中冷却30min,准确称量。恒重灼烧至前后两次称量相差不超过0.5mg。吸取20mL葡萄酒(起泡酒需预先脱气,将100mL试样在室温下使用水平振荡器或超声波水浴脱气,直至无气泡逸出。)置于预先恒重的铂埚或瓷埚中,在恒温水浴锅(5.1)上蒸发至干;之后将盛有蒸发残留物的铂埚或瓷埚置于200℃加热板上碳化:直到不再产生烟为止;再将铂甘或瓷置于525℃土25℃的马弗炉中,灼烧15min;冷却至200℃左右,从马弗炉中取出铂埚或瓷,向铂甘或瓷埚中加入5mL蒸馏水,置于恒温水浴锅上,重新加热、碳化,然后再移人525℃±25℃的马弗炉中灼烧10min。冷却至200℃左右,取出铂埚或瓷,待其在干燥器中冷却后称重。恒重灼烧至前后两次称量相差不超过0.5mg。在盛有20mL葡萄酒的灰分铂埚或瓷甘埚中,加人10ml盐酸标准滴定溶液或硫酸标准滴定溶液(4.5),将铂或瓷置于沸水浴上约15min,用玻璃棒搅拌至灰分完全溶解。加人两滴甲基橙指示剂(4.7),用氢氧化钠标准滴定溶液(4.6)滴定过量的盐酸或硫酸标准滴定溶液,直至指示剂颜色变为黄色。

注:如果碳化不完全,可将碳化残清重新加人5mL燕馏水,燕发掉水分之后,再次灼烧。对于含糖分较高的葡葡酒,最好在第一次灰化前,在蒸发残留物上滴加若干滴纯植物油,以防止产生过多的泡沫。7结果计算

7.1试样中碱性灰分用毫摩尔每升表示,按式(1)或式(2)进行计算:X(10-V))×1 000

式中:

2Xc(10-V)X1000

试样中碱性灰分含量(测定时加盐酸标准滴定溶液),单位为毫摩尔每升(mmol/L);试样中碱性灰分含量(测定时加盐酸标准滴定溶液),单位为毫摩尔每升(mmol/L);盐酸或硫酸标准滴定溶液的浓度,单位为摩尔每升(mol/L);试样消耗氢氧化钠标准滴定溶液体积,单位为毫升(mL)。V

结果保留两位有效数字。免费标准下载网bzxz

2试样中碱性灰分另一种表达方式以碳酸钾计,用克每升表示,按式(3)或式(4)进行计算:7.2

cX10-V)X0.069X1000

;=X(10V)0.138×1 000

式中:

(2)

(3)

·(4

试样中碱性灰分含量(以碳酸钾计)(测定时加盐酸标准滴定溶液),单位为克每升(g/L);试样中碱性灰分含量(以碳酸钾计)(测定时加硫酸标准滴定溶液),单位为克每升(g/L):-KAoNiKAca

盐酸或硫酸标准滴定溶液的浓度,单位为摩尔每升(mol/L);试样消耗氢氧化钠标准滴定溶液体积,单位为毫升(mL);0.069

SN/T4675.27—2016

与1.00mL盐酸标准滴定溶液[c(HCI)=1.000mol/L]相当的碳酸钾的质量,单位为克(g):

与1.00mL硫酸标准滴定溶液[c(H,SO,)=1.000mol/L]相当的碳酸钾的质量,单位为克(g)。

结果保留两位有效数字。

8重复性

以两次平行测定结果的算术平均值作为测定结果,两次平行测定结果的绝对差值不得超过其算术平均值的10%。

KAoNiKAca

SN/T4675.27—2016

Foreword

Standard(SN/T4675)\Methodsofexportwineanalysis\includes30parts:SN/T4675.1Determinationofglycerol inwineforexport-Enzymaticmethod;-SN/T4675.2Determinationof2,3-butanediolinwineforexport-GCmethod;-SN/T 4675.3 Determination of stable carbon isotope ratio of ethanol in wineforexport;SN/T4675.4Determinationof lacticacid inwineforexport-SN/T4675.5DeterminationoforganicacidinwineforexEnzymaticmethod;

port-lonchromatographymethod;-SN/T4675.6Determinationofglucose.fructoseand sucrose inwine forexport;-SN/T4675.7 Determinationofacetaldehyde inwineforexport--GC/MSmethod;—SN/T4675.8Determinationof5-hydroxymeethylfurfural inwinefor export-HPLC method;—SN/T4675.9Determinationof diethyleneinwineforexport--GC/MSmethod;

Ainwine for

HPLC/MS/MSmethod;

-SN/T4675.10Determinationofochratoxinexport-

Determination of7anthyocy

SN/T4675.11D

UHPLCmethod;

-SN/T4675.12Determination of lysozyme in wine for export-HPLCmethod;

—SN/T4675.13Determinationof2,4,6-trichloroanosoleinwineforexport-GC/MSmethod;-SN/T4675.14Determinationofnatamycineinwineforexport—HPLC/MS/MSmethod;SN/T4675.15Determination of salicylic acid,dehydroacetic acid and 4-chlorobenzoic acid in wineforexport-HPLCmethod:

—SN/T 4675.16 Determination of fumaric acid in wine for export-HPLC/MS/MS method;SN/T4675.17Determinationofbutyltincompoundsinwineforexport-GC/MS/MSmethod;SN/T4675.18Determinationofdithiocarbamates(salt)residuesinwinefor export-Headspace4

KAOKAca

GCmethod;

SN/T4675.27—2016

-SN/T4675.19Determinationof sodium,magnesium,potassium,calcium,chromium,manganese,ironcopperzinc,arsenic,selenium,silvercadmiumandleadinwineforexportSN/T4675.20Determinationof rare-earthelementsinwineforexport-ICP-MSmethod;SN/T4675.21

method

Determination of soluble inorganic salts in wine for export-lon chromatography-SN/T4675.22Determination oftotal sulfurdioxide in wineforexport-Colorimetricmethod;-SN/T4675.23Determination ofammoniumnitrogen in wineand grape juiceforexport-Continu-ousflowanalysis(CFA)method:

-SN/T4675.24Determinationof Folin&Ciocalteu indexmethod;

—SN/T4675.25

spacesystem;

fwineforexport-Spectrophotometryexport-CIELabcolor

Determination of chromatic characteristics of winefor—SN/T4675.26

Determination of turbidity

fwineforexport-Diffused radiationmethod-SN/T4675.27Determinationofalkalineashofwineforexpont:

-SN/T4675.28Method for enumeration of colony-forming units of yeasts,moulds and bacteria incork stoppers and wine for export;—SN/T4675.29Determinationofbrettanomycesin wineforexport

-SN/T4675.30

eal-timePCRmethod;

Determination of zygosaccharomyces baili in wine for export-Real-time PCRThis part is part27of the standardThispart isdrafted accordingtoGB/T1.1—2009This part completely adopted the method of Organization of International Vine and wine (OlV) MA-AS2-04,\Ashof Wines\and modified MA-As2-05\Alkalinity of Ashof WinesTitrimetricMethod”.Thetechnical contentwas the sameexcept for sometechnical changesas follows:-Porcelaincruciblewasincreased:5

TKAoNIKAca

SN/T4675.27—2016

—Hydrochloricacid standard titration solution(0.1000mol/L)was increased;-Formulaofx3

c×10-V,)0.069x1000

wasincreased

Please note that some of the content of the standard may involvepatents.Publication of the presentstandard does not bear the responsibility of identifying these patents.This part was proposed by and was under the jurisdiction of Certification and Accreditation Adminis-trationofthePeople'sRepublicofChina.This part was drafted by Zhongshan Entry-Exit Inspection and QuarantineBureau of thePeople's Republic of China,Huangpu Entry-Exit Inspection and Quarantine Bureau of the People's Republic ofChina and Guangdong Entry-Exit Inspection and Quarantine Bureauof thePeople's Republic of China.Themain drafters of this part were Feng Xueya,Li Rong,Tian Ling,Li Yunsong,Li Haoyang,Xie Lifang,LiangJianyu,HeXingzong,Liu Qingand Li Zhiyong.1

SN/T4675.27—2016

Determinationof alkalineashinwineforexportScope

This part specifies the method for the determination of alkalinity ash in wine.This part is applicable to the determination of alkalinityash in wine.2

Quotednormativedocuments

The following referenced documents are indispensable for the application of this document.Fordated references,only edition cited applies.For undated references,the latest edition of the refer-enced document(including any amendments)applies.GB/T601

Chemical reagent-Preparations of standardvolumentric solutions2Water foranalytical laboratoryuse-Specification and testmethods.GB/T6682

Principle

The ash is dissolved in acid standard titration solution,the excess acid solution is determined by Al-kali standard titration solution,the consumption of alkali content multiplied by the conversion coeffi.cientfactoristhealkalinityof ash4

Reagents and materials

Unless others specified,the reagents should be analytical pure. And the water should accord withGB/T6682

Methylorange(CiaH1N,SO,Na).

Hydrochloric acid (HCl),

Sulfuricacid(H,SO4).

Sodiumhydroxide(NaOH)

SN/T4675.27—2016

4.5Hydrochloric acid standard titration solution (o.1000 mol/L)or sulfuric acid standard solution(o.050omol/L):PreparationandcalibrationofGB/T601.4.6Sodium hydroxide standard titration solution(0.1000 mol/L):Preparation and calibration ofGB/T601.

4.7Methylorange indicator(0.1%)Take0.1gmethylorange(4.1),dissolved with a small amountofwater,transferredtoavolumetricflask(100mL),diluteto100mL.5Apparatus and equipment

5.1Thermostaticbath.

5.2Analysis balance:sensitive to0.1mg.5.3 Heatingplate.

Dryer(desiccant).

5.5 Platinum crucible or porcelain crucible.Mufflefurnace.

Alkali Burette:10 mL

Glass rod.

5.9Horizontal oscillatortuble.5.10

Ultrasonic bath.

6Analyticalprocedure

Put platinum crucible or porcelain crucible(5.5)in a muffle furnace (5.6),burning for 30 min at525℃±25,cooling to200,removeand place ina dryer(5.4)coolingfor30 min,accuratelyweighing.Burning to constant weight,the weight difference of before and after burning times is un-der0.5mg.

Pipette20 mL wine(sparkling wine need to pre-degas,100 mL sample willbe degassedbyhorizontaloscillator or ultrasonic waveat room temperature until no bubles) into the previously platinum cruci-ble or porcelain crucible(constant weight),evaporate sample wine to dry on the Thermostatic bath8

SN/T4675.27—2016

(5.1),then carbonizing the evaporating residues on the heating plate at 20o ℃,until no smog ap-peared.Put the crucible into the furnace and burn for 15min at 525℃ ±25℃,cooling to 200 ℃,andtake out the crucible and add 5 mL water,and put into Thermostatic bath(5.1),then re-heating,re-carbonizing.then put into muffle furnace,burning for 10 mins,cooling to 20o C,take out platinumcrucible or porcelain crucible,then weigh it after being cooled in dryer.Burning to constant weight,the weight difference of before and after burning times is under o.5mg.Add 10 mL hydrochloric acid standard titration solution or sulfuric acid standard solution(4.5) to theash from 20 mL of wine in the platinum crucible or porcelain crucible.Place the crucible on the boilingwater-bathforabout15

irringthesolutionbyglassroduntil theashwastotallydissolved.Add two drops of methyl orange solution (4.7)and titrate the excess hydrochloric acid orsulfuric acid against sodium hydroxide standard titration solution(4.6)until the color of the indicatorchangestoyellow.

tcompletely.canre-add5mLdistilledwaterthenevaporatedwa-Note:if the carbonization was notters,burning again. For some sample wine which include high sugar content.when firstlycarbonizing,itwillbebettertodropsomepla7

Expression of results

n samplewineforpreventingfoam.7.1In the sample,the alkaline ash contentexpressed in milliequivalents per liter was calculated byformula(1)orformula(2)

×1000

2xC×(10-V)×1000

Where:

·(2)

x,alkaline ash content in the sample,(determination of the hydrochloric acid standard titration so-lution)mmol/L;

X2the alkalineash content in the sample,(determination of the sulfuric standard titration solution)mmol/L:

c the concentration of the standard titration solution of hydrochloric acid or sulfuric acid,mol/L;V,-thevolumeof the sampleconsumptionof sodiumhydroxidestandardtitrationsolution,mL;The result is kept to two decimal places.9

小提示:此标准内容仅展示完整标准里的部分截取内容,若需要完整标准请到上方自行免费下载完整标准文档。